JIANGSU CHUANGPUAN MACHINERY TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

The Mango Pulp Production Line is a highly efficient and customizable production system designed for the processing of mangoes into high-quality pulp, juice, and other related products. This state-of-the-art production line is equipped with advanced machinery and technology, making it the perfect solution for businesses looking to streamline their mango processing process.

The Mango Pulp Production Line consists of the following components:

Together, these components work seamlessly to produce high-quality mango pulp and juice that meet industry standards and customer expectations.

The Mango Pulp Production Line offers numerous benefits for businesses, including:

The Mango Pulp Production Line is a top-of-the-line solution for businesses looking to optimize their mango processing process. With its customizable options, efficient components, and high-quality output, this production line is a valuable asset for any mango processing facility. Invest in the Mango Pulp Production Line today and take your mango processing to the next level!

| Brand | CHUANGPUAN |

|---|---|

| Size | 40000*20000*8000mm |

| Power | 20-150KW |

| Processing | Pulping |

| Application | Mango Pulp Processing |

| Voltage | 380V,415V,440V,460V Customized |

| Warranty | Two Year |

| Weight | 10000KG According To Actual |

| Delivery | 40-70days |

| Capacity | 0.5-20T/H |

| Key Features | mango evaporating machine, mango juice make machine, automatic mango pulp process machine |

CHUANGPUAN Mango Pulp Production Line is a high-quality and efficient mango processing equipment manufactured by our factory in China. Our brand name is CHUANGPUAN, and our model number is CPA-MJ. Our production line is suitable for processing mangoes into pulp and can handle a capacity of 0.5-20 tons per hour.

Our Mango Pulp Production Line is widely used in various food processing industries, such as fruit processing factories, juice production plants, and food processing companies. It is specifically designed for the production of mango pulp, which is an essential ingredient for making various mango-based products, such as juices, jams, and yogurts.

Imagine a bustling mango processing factory where workers are busy sorting, washing, and cutting fresh mangoes. In one corner, our CHUANGPUAN Mango Pulp Production Line is in full operation, smoothly turning the mangoes into juicy and smooth pulp. The stainless steel material of the production line ensures the cleanliness and hygiene of the process, while the efficient capacity of 0.5-20 tons per hour allows for a large volume of production.

Meanwhile, in another part of the factory, the mango pulp is being used to make various products, such as mango juice, jam, and yogurt. With the help of our production line, the process is quick and seamless, resulting in high-quality and delicious mango-based products. Our CE and ISO9001 certifications guarantee the safety and reliability of our Mango Pulp Production Line, giving both the producer and consumers peace of mind.

Outside the factory, our customers are satisfied with the performance of our product and the customized packaging that meets their specific requirements. They know that our delivery time of 40-70 working days can be trusted, and our flexible payment terms of T/T, L/C, and Western Union make the transaction smooth and convenient.

Overall, the CHUANGPUAN Mango Pulp Production Line proves to be an essential and reliable equipment for any mango processing factory, providing a seamless and efficient production process and producing high-quality and tasty mango-based products.

Our Mango Pulp Production Line is carefully packaged to ensure safe delivery to our customers. Each component is individually wrapped and placed in sturdy boxes to prevent damage during shipping.

The packaging process includes thorough quality checks to ensure that all components are in perfect condition before being packed. We use high-quality materials to protect the equipment from any external factors that may cause damage.

Once the equipment is packaged, it is loaded onto pallets and securely strapped to prevent shifting during transportation. Our packaging team pays attention to every detail to ensure that the equipment arrives in pristine condition.

For shipping, we partner with reliable freight companies to ensure timely and efficient delivery to our customers. Our team works closely with the freight company to provide accurate tracking information and updates on the status of the shipment.

In addition, we offer customization options for packaging and shipping to meet the specific requirements of our customers. This includes using different packaging materials, labeling, and shipment methods.

With our meticulous packaging and shipping process, you can be assured that your Mango Pulp Production Line will arrive safely and ready to use. Contact us for more information on our packaging and shipping options.

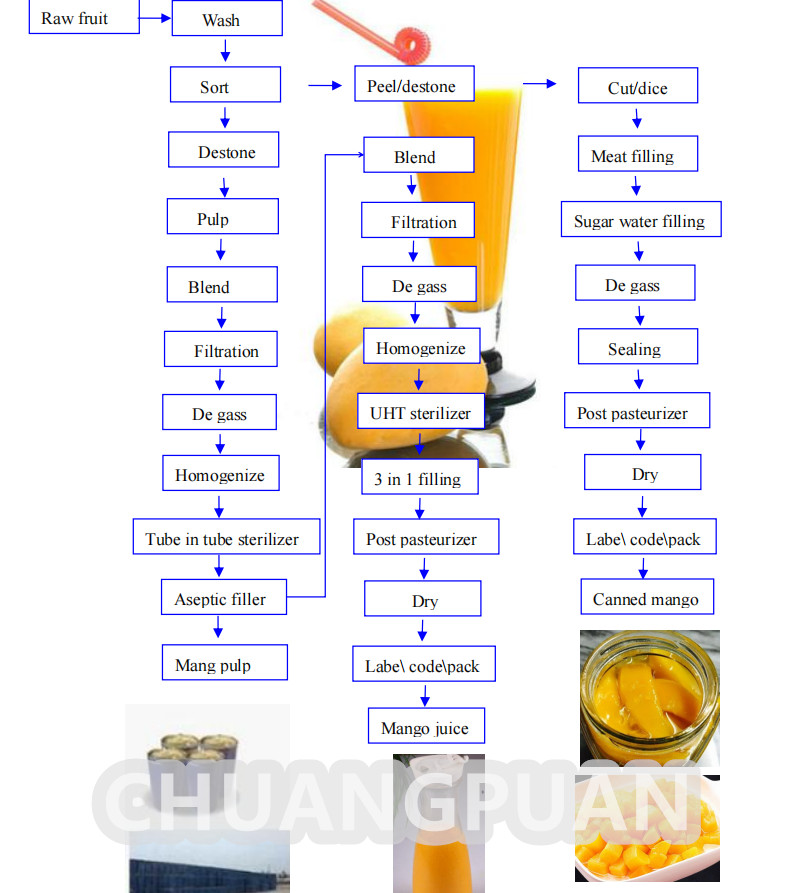

mango -wash-sort-destone-pulp-blend-filtration-de gass-homogenize-tubu in tube sterilizer-aseptic filler-mango pulp products

mango pulp-blend-filtration-de gass-homogenize-UHT sterilizer-three in one filling-dry-label/code/pack-mango juice products

mango-wash-sort-peel/destone-cut/dice-meat filling-sugar water filling-de gass -sealing-post pasteurizer-dry-label/code/pack-canned mango products