JIANGSU CHUANGPUAN MACHINERY TECHNOLOGY CO.,LTD |

|

Verified Suppliers

|

|

The Mango Pulp Production Line is a state-of-the-art machine designed for efficient and high-quality processing of mangoes. With its advanced technology and high production capacity, it is the perfect solution for mango processing companies looking to increase their productivity and produce superior quality mango pulp.

The Mango Pulp Production Line has a compact size and measures 40000*20000*8000mm, making it suitable for use in smaller processing facilities. It has a power range of 20-150KW, providing the necessary energy for a smooth and efficient production process. The machine weighs 10000KG according to actual specifications, ensuring stability and durability during operation.

The main function of the Mango Pulp Production Line is to process mangoes into high-quality pulp. It is equipped with various machines and equipment that work seamlessly together to achieve this goal. The key functions of each machine in the production line are:

With these functions combined, the Mango Pulp Production Line is able to efficiently and effectively produce high-quality mango pulp, meeting the demands of the market.

The Mango Pulp Production Line has a delivery time of 40-70 days, depending on the location of the customer and their specific requirements. Our team of experts will work closely with you to ensure a timely delivery and installation of the machine at your facility. We also provide after-sales support to ensure the smooth operation of the production line.

The Mango Pulp Production Line is a must-have for any mango processing company looking to increase their production capacity and maintain the highest standards of quality. With its compact size, advanced technology, and efficient functions, it is the perfect solution for a successful mango processing operation.

| Product Name | Mango Juice Production Line |

|---|---|

| Brand | CHUANGPUAN |

| Delivery | 40-70 days |

| Processing | Pulping |

| Weight | 10000 KG According To Actual |

| Warranty | Two Year |

| Application | Mango Pulp Processing |

| Capacity | 0.5-20T/H |

| Power | 20-150KW |

| Function | Mango Processing |

The Mango Pulp Production Line by CHUANGPUAN is a state-of-the-art processing plant designed specifically for the production of high-quality mango pulp. This production line is perfect for businesses looking to enter the lucrative mango pulp market or for those looking to upgrade their existing processing facilities.

The Mango Pulp Production Line is ideal for processing mangoes into pulp for various purposes such as juice, jams, jellies, and other food products. It is widely used in fruit processing factories, food and beverage industries, and agricultural cooperatives. This production line is suitable for both small-scale and large-scale production, making it a versatile choice for all types of businesses.

The Mango Pulp Production Line is made of high-quality stainless steel, ensuring durability and hygiene. It consists of a series of machines, each performing a specific function in the production process. These machines include washing machines, sorting and grading machines, pulping machines, refining machines, and filling machines. The production line is designed for high efficiency, with minimal waste and maximum output.

The Mango Pulp Production Line can be customized according to the specific needs and requirements of each customer. The size, voltage, and packaging can be adjusted to fit the production facility and budget of the customer. Our team of experts will work closely with you to ensure that the production line meets all your business needs.

The Mango Pulp Production Line by CHUANGPUAN is the perfect solution for businesses looking to enter the mango pulp market or upgrade their existing facilities. With its high-quality materials, customizable options, and efficient production process, it is a reliable and cost-effective choice for all types of businesses. Contact us today to discuss your mango pulp production needs and we will provide you with a tailored solution that meets all your requirements.

| Brand Name | CHUANGPUAN |

|---|---|

| Model Number | CPA-MJ |

| Place of Origin | CHINA |

| Certification | ISO9001, CE |

| Minimum Order Quantity | 1 SET |

| Price | NEGOTIATION |

| Packaging Details | CUSTOMIZED |

| Delivery Time | 40-70 WORKING DAYS |

| Payment Terms | T/T, L/C, WESTERN UNION |

| Supply Ability | 30 SETS ONE YEAR |

| Application | Mango Pulp Processing |

| Material | Stainless Steel |

| Voltage | 380V, 415V, 440V, 460V Customized |

| Size | 40000*20000*8000mm |

| Brand | CHUANGPUAN |

The Mango Pulp Production Line is carefully packaged and shipped to ensure safe delivery and arrival at your desired location. Our packaging process is designed to protect the equipment from any damage during transportation.

The entire production line is packed in sturdy wooden crates, which are then securely strapped and loaded onto pallets for easy handling. The crates are also marked with clear labeling to indicate the contents and handling instructions.

We work with reputable shipping companies to ensure timely and efficient delivery of our products. Our experienced logistics team coordinates the shipping process and keeps you updated on the status of your order. We also provide necessary documentation for international shipments, including customs clearance and export permits.

Upon arrival at your location, our team will assist with unloading and installation of the production line. We also offer on-site training and technical support to ensure smooth operation and maintenance of the equipment.

With our reliable packaging and shipping methods, you can trust that your Mango Pulp Production Line will arrive in perfect condition and ready to use.

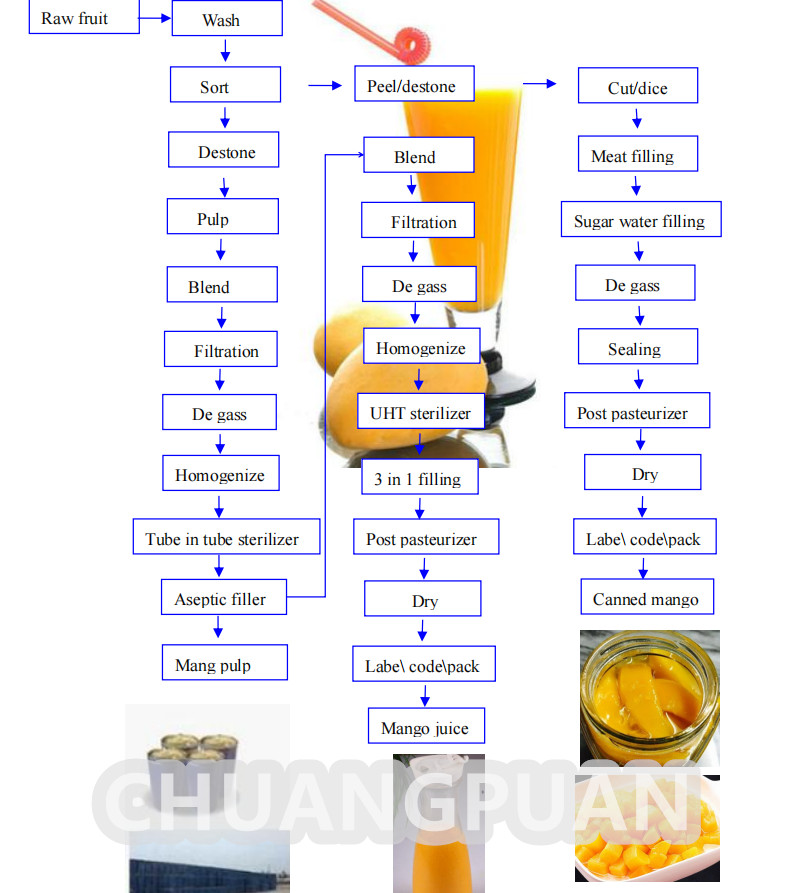

mango -wash-sort-destone-pulp-blend-filtration-de gass-homogenize-tubu in tube sterilizer-aseptic filler-mango pulp products

mango pulp-blend-filtration-de gass-homogenize-UHT sterilizer-three in one filling-dry-label/code/pack-mango juice products

mango-wash-sort-peel/destone-cut/dice-meat filling-sugar water filling-de gass -sealing-post pasteurizer-dry-label/code/pack-canned mango products