Shenzhen Kunhe Precision Hardware Co., Ltd. |

|

Verified Suppliers

|

|

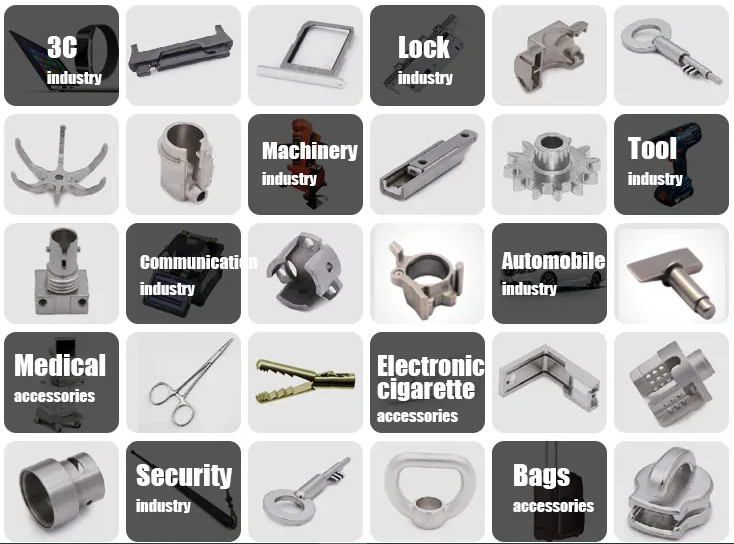

Factory price Mim metal powder injectioin parts metallurgy stainless steel ODM OEM decorative for home furnitures

Feature

High-quality material: Our metal injection molding (MIM) parts are made from high-quality stainless steel, ensuring durability and longevity.

Sandblasting finish: We use sandblasting to achieve a smooth and uniform finish on our MIM parts. This process not only enhances the appearance of the parts but also provides added protection against corrosion and wear.

Ideal for home furniture: Our MIM parts are ideal for use in home furniture, thanks to their superior strength and resistance to wear and tear.

Precision manufacturing: Our state-of-the-art manufacturing process ensures that our MIM parts are of the highest quality and meet the exacting specifications required for use in home furniture.

Customizable options: We offer a wide range of customizable options for our MIM parts, allowing our customers to choose the size, shape, and finish that best meets their needs. Whether it's for a one-of-a-kind piece or a large-scale production run, we have the expertise and technology to deliver the perfect MIM parts for your home furniture.

Product Description:

Specification:

| Attribute | Details |

|---|---|

| Brand name | OEM & ODM |

| Product type | MIM parts |

| Product Model | MIM |

| Material | Stainless steel 304,316L,17-4PH,TI |

| Forming Method | Powder Injection Molding |

| Mold material | Steel |

| Sintering method | Solid-phase sintering |

| Sintering environment | Vacuum |

| Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

| Size | Base on drawing or requirement |

| Tolerance | 10mm±(0.02-0.04)mm |

| Weight | ≤200g |

| Shape | Custom |

| Application | Decorative industry |

| OEM | Accept |

| QC system | 100% inspection before shipment |

| Payment terms | T/T at sight, Paypal, Western Union, etc. |

| Lead time | 15-20 working days |

| Supply capability | 500000 Piece Per Month |

| Packaging | PP bag / Anti-static film / anti-static plastic disc |

===================================================================================

advantages.

our sales team:

Manufacturing process: CNC stamping, CNC lathe, CNC milling, CNC machining, laser cutting, CNC MIM.

Drawing accepted: SOLIDWORKS, PROE, CAD, PDF, STP,IGS,

Quality assurance: ISO09001:2018, ROHS, TUV, IATF16949

Payment terms: by western union, paypal, T/T wiring, Payoneer, Moneygram.

Deliver terms: by UPS, Fedex, TNT, DHL, airfreight, seafreight.

Client visiting gathering pictures: