Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Can't find a reliable supplier for Glazed Corrugated Sheet Roll

Forming Machine ? Huachen is your best choise.

Cangzhou huachen roll forming machinery Co., Ltd is the

manufacturer specilized in metal roofing roll forming machine. We

provide an extensive line of products, which includes roof and wall

panel machine , roof tile machine, purline forming machine, floor

decking machine,gutter forming machine,roller shutter machine etc.

What's your machine application ?

Our roll forming machines can produce various of steel roof and

wall panel, it is a new building materials, the products are widely

used as the roof and wall of factory, warehouse, garage, gymnasium,

exhibition center, cinema, theatre, etc. It has many advantages,

such as easy installation, short building period, beauty, light

weight but high strength.

Quick Detail:

1. Suitable to process: Color steel plate

2. Width of the plate: 1200mm

3. Rollers: 12 rows

4. Dimensions: 7.2*1.55*1.51m

5. Power: 4+4kw

6. Rolling material: 45# steel(plated chrome on surface)

7. Thickness of the plate:0.3-0.6mm

8. Voltage: 380V 50Hz 3phases

9. Material of the cutting plate: Cr12

10. Hydraulic: 40#

11. Processing precision: Within 1.00mm

12. Control system: PLC control

Description:

Glazed Tile Roll Forming Machine Main parameter

No. | Main parameter of Glazed Tile Roll Forming Machine | |

1 | Suitable to process | Color steel plate |

2 | Width of the plate | 1200mm |

3 | Rollers | 12 rows |

4 | Dimensions | 7200*1550*1510m |

5 | Power | 4+4kw |

6 | Rolling material | 45# steel(plated chrome on surface) |

6 | Thickness of the plate | 0.3-0.6mm |

7 | Productivity | 4m/min |

8 | Diameter of the roller | Φ70mm |

9 | Voltage | 380V 50Hz 3phases |

10 | Material of the cutting plate | Cr12 |

11 | Hydraulic | 40# |

12 | Processing precision | Within 1.00mm |

13 | Control system | PLC control |

Equipment components: Man-made uncoiler-roll forming machine-computer control system-hydraulic control system-press form-cutting

Application

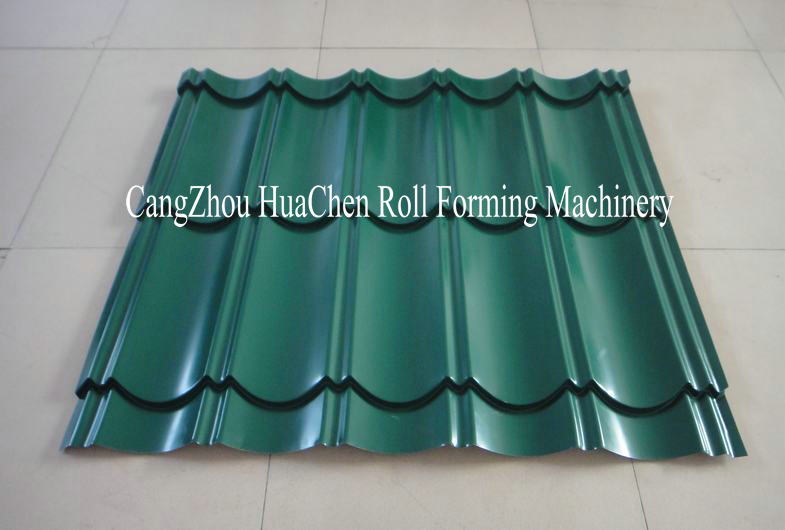

This type of glazed tile has advantage inclouding beautiful, classical appearance and grace taste. It can be widely used in village, hotel, exhibition, vocation vallage, family construction and outdoor decorate.

Competitive Advantage

1. CE certification

2. hydraulic motor drive

3. Exported to more than 70 countries

4. suitable for various kinds of steel plate

5. voltage according to customer request

Clear about working process for Roll Forming Machine ?

Decoiling--Feeding & Guiding--Roll Forming--Step

pressing--Cutting--Finished Products To Support Table

Why choose Huachen ?

1.Q: Do you have after sales support?

A: Yes, we are happy to give advice on machine operating and

maintenance. we also have skilled technicians available abroad to

help you.We need your machines running in order to keep your

business running.

2.Q: How do your machines compare with other big companies in this

market?

A: We are up to date with the latest technology and improve our

machines accordingly .We need to make gress to move forward.

3.Q: How does your factory do regarding quality control?

A: Quality is priority.To all Huachen people,the concept "Control

every process and perfect all products" is curved in mind. Every

product will be fully assembled and carefully tested before it's

packed for shipment.

4.Q: Do you sell only standard machines?

A: No, most of our machines are designed according to customers

specifications,we offer OEM service.

5.Q: Will you deliver the right goods as ordered? How can I trust

you?

A: Yes, we will. welcome to come and check your machine after

finished, or we will show you machine working video for confirm.

Then delivery.