Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

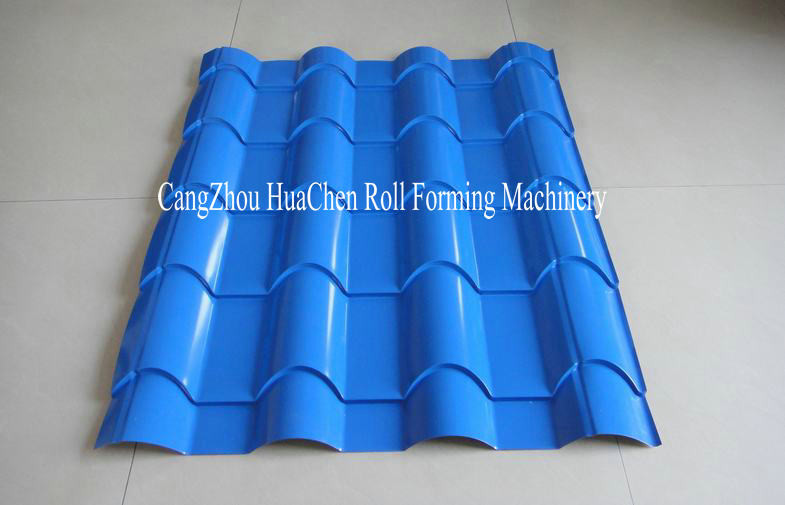

Metal Panel Cold Roller Forming Equipment

Glazed tile making machine, is used to produce glazed tile.

Machine components: glazed tile glazed tile making machine from the external structure to see by the loading frame, loading frame support, feed guide device, forming host, punching device, forming shear device, hydraulic station, computer control cabinet and other components.

We can also supply the customized machines.

Application for Roofing Tile Rollformer

The finished products are widely used in garden-like factories, tourist scenic spots, pavilions and pavilions, hotel villas, exhibition halls, resorts, resorts and so on. It has many advantages, such as beautiful scenery, Home and other architectural and outdoor decoration.

| Material Width | 1250mm |

| Rolling Speed | 4-5m/min (press step in 350mm, product length in 6m) |

| Rolling Thickness | 0.4-0.6mm (235Mpa) (Colored Steel plate) |

| Control System | PLC (Panasonic) |

| Roller Stations | About 16 stations |

| Diameter of Shaft | ¢76mm solid shaft |

| Motor Power | Decoiler: 13KW Main Power: 7.5KW servo motor Hydraulic power: 11KW

|

| Structure | Guide pillar structure |

| Way Of Drive | By chain, one complete chain |

Our services

…………………………………………………………………………………………………………………………………………………………………………………

Provide Pre-sales Consultant & On-purchase service 8 hr × 6 days per week

1. Reply within 24 hours

2. Provide relevant product information

3. Answer questions if request

4. Give technical suggestion

Provide After-sales service 24hr × 7days per week

1. Test the machine before shipment

2. Provide technical guidance relate to use the machine

3. Supply one-year warranty period for the machine

4. Provide the spare parts at cost price after warranty period

5. Collect the feedback for the machine working