Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

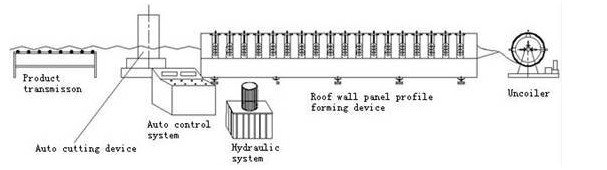

The chart of process flow

Decoiling—active feeding (put the coil strip into the first feeding roller)—leveling —roll forming —computer control system—hydraulic cutting—product to stand

Equipment technical parameters

| Molding host | Model | Shibo- shutters slat roll former |

| Forming size | 4500mm*1500mm*1300mm | |

| weight | 2.5 T | |

| Host big frame structure | Frame welded | |

| Roll station | 14row | |

| Axial material | 45# steel | |

| Out diameter of shaft | Φ75mm | |

| Roller materials | 45# steel hard chromium plating | |

| Drive | By chain | |

| Sprocket chain | 1 inch | |

| Main power | 4 + 4 kw | |

| Working speed | 8-12 m/min | |

| Material thickness | 0.3-0.8mm | |

| Made board | 25mm |

Hydraulic shearing

| Material of blade | Cr12,heat treatment 60-62HRC |

| Shearing system | shutters slat forming machine is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job. The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves. Power of the oil pump: 3kw Hydraulic oil :40# |

Electrical system

| Main computer control cabinet | shutters slat roll former adopts industrial computer to control. The target piece’s length is adjustable and digit of it can be adjusted. Computer mode has two modes: automatic and manual one. The system is easy to operate and use. Processing precision : within 1.00mm It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part. Transducer brand is EURA. The seller will provide Chinese and English language screen. |

Q1:If our country's voltage is different from yours, how to solve

that?

A1:The usual voltage is 380v,220v,415v. If yours are not one of

them, we will design the electric motor to suit your voltage.

Q2:We bought your shutters slat roll former, but we couldn't

install and debug it?

A2:Don't worry about that, when finished the machine, we will send

you the manual book which shows how to use the machine; if you

still don't know, we can record a video to teach you how to operate

the machine.

Q3:About the after service, what you can serve?

A3:All the machines are two years guaranteed, life maintenance. We

can send the technician abroard, but you should pay the round-trip

cost.