Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Strong Ridge Cap Forming Machine,roll forming machine

The ridge cap roll forming machine can roll formed metal ridge which is mostly used with colorful roofing tile sheets. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface. We can design the machine according to your specification and profile drawing. This product is widely used in many kinds of industrial factory and civilian buildings. It has advantages of its pretty appearance and durability.

Machine Configuration:

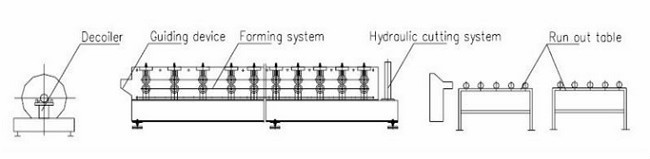

Decoiler, Feeding Applicator, Roll Forming Machine, Computer Control System, Hydraulic Cutting,Output Table

Working Flow:

Decoiler—Feeding Applicator—Roll Forming Machine—Computer Contol System— Hydraulic Cutting—Output Table

Specification:

| Item NO | Description | Offered specification |

| 1.0 | Roll forming machine | Roof sheet |

| 1.1 | Rolling speed | 15-20m/min |

| 1.2 | Rolling thickness | 0.25-0.8mm |

| 1.3 | Raw material | Galvanized steel sheet & pre-painted steel sheet up to 550mpa |

| 1.4 | Control system | PLC & Transducer(Mitsubishi ) |

| 1.6 | dimension | 7000×1500×1500(mm) |

| 1.7 | The material width | 6000mm |

| 1.8 | Effective width | 312/415mm |

| 1.9 | Roller stations | 25 stations |

| 1.10 | Roller material | 45#forge steel, coated with chrome |

| 1.11 | Shaft diameter | φ75mm ,material is 45# forge steel |

| 1.12 | Transmission | By chain |

| 1.13 | Material of chain | 45# forged steel with frequency quenching, 16A |

| 1.14 | Main motor power | 7.5kw |

| 1.15 | Hydraulic station power | 3.0kw |

| 1.16 | Hydraulic pressure | 12Mpa |

| 1.17 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.18 | Tolerance | 10m+-2mm |

| 1.19 | Electric source | 415 volts, 3 phase and 50 Hz or at buyer’s request |

| 1.20 | Frame | 350mmX175mm H type steel |

| 1.21 | Color of the machine | According customer’s requirements dark green |

| 1.22 | Container need | 1 x40 feet( machine will be fixed by string in the container) |