Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

1. Description:

This model of machine is exported to Euro market.The feeding width is 1250mm,and cover width is 1050,it is perfectly overlapped.Save material and out look is beautiful.The cutting device is different from the normal glazed roll forming machine,its curve cutting,cut the tile shape accordingly.

2. Competitive Advantage:

1. save space

2. easy installation

3. perfect service

4. excellent quality

5. Operate easily

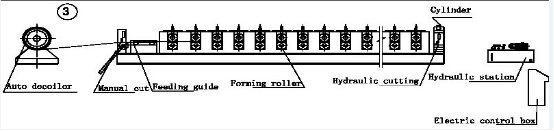

3. Flow chart

4. Specification

| NO. | ITEM | PARAMETER | NOTE | |

| 1 | Suitable | Type | Pre-painted sheet, | |

| material | Galvanized sheet | |||

| Galvanized Aluminum | ||||

| Width(mm) | 1250mm | |||

| Thickness(mm) | 0.3-0.8mm | |||

| Yield stress(mm) | Q235 | |||

| 2 | Product | Detail as the attached file | ||

| specifications | Length | Any length | ||

| 3 | Power | Type | 380v/3ph/50hz | Motor brand shanghai |

| Main Motor power | 7.5kw | |||

| requirement | ||||

| 4 | Forming speed(m/min) | 2-10m/min | Not include the time | |

| of cutting | ||||

| Suitable coil OD(MM) | 1250 | |||

| (Optional) | Suitable coil | 508 | ||

| ID(MM) | ||||

| 6 | Forming stand | 12 | Depend on actual design | |

| 7 | Thickness of structure | 16mm | ||

| 8 | Forming shaft diameter(mm) | 70 solid | ||

| 9 | Type of cutting | Roll formed and length-set cutting | ||

| 10 | Control system | Panasonic PLC and inverter | ||

| 11 | Install dimension(depend on the final design) | 9.3m×1.5m×1.2m | Without panel length | |

| 12 | Total weight (Approx) | 6T | Depend on final design | |

5. Applications:

| Our machine | Other company 's machine | Influence of the machine | |

| Machine's base | High strength H350 / H400 steel. machine through milling macine after welding | H270 steel mark, after welding use manual polish | keep base in the same horizontal line, ensure product standard |

| Roller material | High grade No.45 forged steel, with digital-controlled procession, Plated with 5 um chrome coated | Normal No. 45 steel with Simple polished and have no coating | Roller will have longer use life and ensure the products have same size,no nick on the surface. |

| Side wall | Use high strength16mm thickness steel panel mark | Use 12 mm thickness steel panel mark | Ensure machine harder to deform, keep the product accurate and stable |

| Active shaft material | High grade solid No.45 carbon steel, Shaft diameter is 70mm. surface CNC polish treatmen | Normal No. 45 steel with no surface treatment | Improve the integrated mechanic feature of the shaft. and ensure the shaft stability keep product standard |

| Electrical elements | PLC control panel, transducer imported from Panasonic of Japan. Other elements from famous suppliers in China | All the elements are made in china | Machine become more accurate and more stable |

| Cutter blade | Cr12 mould steel with quenched treatment | Normal high strength steel without quenched treatment | Stable the integrated mechanic feature of the cutter blade,harder to deform, longer blade's life, ensure product standard |