Cangzhou Huachen Roll Forming Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Combined U channel C stud Light Keel Rolling Forming Machine

Combined U channel C stud Light Keel Rolling Forming Machine

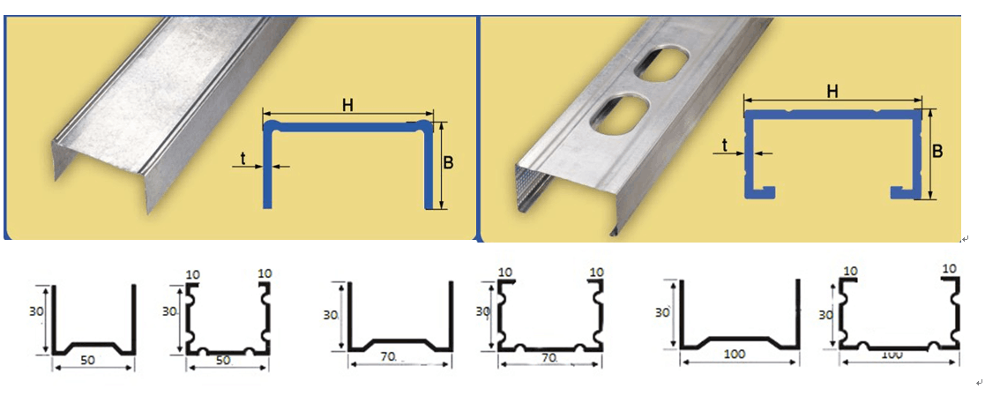

Combined U channel C stud Light Keel Rolling Forming Machine is designed based on the customer requirements. For one thing, it can save the factory sapce and save production cost. The stud and truck are frequenntly used in drywall making and ceiling making. Here are some drawing profiles for your reference:

What is stud and track profile and how it is used?

Combined UC light keel machine could be used to make C stud and U track by one machine and you do not need to adjust spacer. The combined U track and C stud machine is like making two machine together but using one set of electricity system, PLC control system and machine frame. By this method, the combined machine takes little space and save some money. For any sizes U track and C stud could be combined together.

How the combined U channel C stud Light Keel Rolling Forming Machine is designed?

Same with the entire roll forming machine, this combined light keel machine is composed by Decoiler, leveling beach, roll forming machine, shearing system and others. But the main machine will have some different. Here is the detail machine picture for your reference:

Description:

Keel Roll Forming Machine Main parameter

No. | Main parameter of Keel Roll Forming Machine | |

1 | Suitable to process | Color steel plate |

2 | Width of the plate | 175 mm |

3 | Rollers | 12 rows |

4 | Dimensions | 6100*1150*1510mm |

5 | Power | 4.5+3kw |

6 | Rolling material | shaft bearing steel(quenching) |

7 | Thickness of the plate | 0.3-0.6 mm |

8 | Productivity | 20m/min |

9 | Diameter of the roller | Φ50mm |

10 | Voltage | 380V 50Hz 3phases |

11 | Material of the cutting plate | Cr12 |

12 | Hydraulic | 40# |

13 | Processing precision | Within 1.00mm |

14 | Control system | PLC control |

Equipment components: Man-made uncoiler-roll forming machine-computer control system-hydraulic control system-cutting

Why choose combine U track and C stud machine?

1. Small machine design, it takes small space in the factory. If you factory has small space, please choose this type.

2. For the U track and C stud, you do not need to change roller and adjust the spacer.

3. Lower cost, as the two drawing profiles could be made by one machine, one PLC control system, one set of motors.

Some more detail parameters of the machine for your reference:

| Manual decoiler | ||||

| Material coil inner diameter | 450mm-550mm | |||

| Max coil width | 300mm | |||

| Carrying capacity | 1500kg | |||

| Main roll forming machine | ||||

| Number of forming steps | 9 stations | |||

| Shaft material:45# steel Outer diameter | 50mm | |||

| Roller material: | Cr12MoV | |||

| Transport | by gear | |||

| Forming speed: | 15-20m/min | |||

| Motor | 7.5kw | |||

| Voltage | 380v,50Hz,3 phase | |||

| Shearing system | ||||

| Usage | Together with punching words, cutting will be done together. | |||

| Material of blades | Gcr12 quenched | |||

| Power supply | hydraulic power | |||

| Frame | Pillar style with rack & pinion system | |||

| Stroke switch | non-contact photoelectric switch | |||

| Hydraulic Station | ||||

| Hydraulic motor Power | 3kw | |||

| Hydraulic oil | 46# | |||

| Components | The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves. | |||

| Electric Control System | ||||

| Feature | 1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2. Other electric element is Delta. 3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety. | |||

| Brand | Panasonic | |||