Wuhan Global Metal Engineering Co., Ltd |

|

Verified Suppliers

|

|

Pressed In Brass Coil Heater with Stainless Steel Armor For Hot Runner Nozzle

1. Brief Introduction

The Pressed in brass coil heater is made of Germany heater wire ,the united states high-purity magnesium oxide materials and strict process technology,there are various sections and sizes,square ,round and flat cross sections and sizes available ,provide high –performance electric heater for heating hot runner mold and other fileds. Heaters maximum temperature up to 700C.The integration of temperature thermocouple for precise temperature control ,can provide K J E themocuple ,blasting and black surface treatment ,also provides bright surface.

The Armored Nozzle Coil Heater are constructed with a Stainless Steel inner sleeve and a Stainless Steel outer sleeve. The heater is tightly sandwiched between these sleeves eliminating the heat transfer problems associated with other dual sleeved designs.

The materials used direct the heat inward toward the nozzle resulting in a very efficient heater with even heat distribution. The tightly toleranced I.D allows a slip fit with no clamping required.

2. Specification

| Sheath material | Chrome Nickel Steel |

| Insulation material | High purity MgO |

| Heating element | NiCr 80:20 |

| Thermocouple | 'J' type (Fe K) 'K' type (Cr Al) grounded or ungrounded |

| Connection Wires | Stranded Nickel wires with PTFE coating |

| Power Tolerance | (+5% ,-10%) (smaller tolerances on request ) |

| Insulation Resistance | ≥ 500 MΩ at 500V AC |

| Current Leakage | ≤ 0.5 mA at 253V AC |

| Sheath Temperature | 750°C |

| Dielectric strength (high voltage test ) | Min. 1000V |

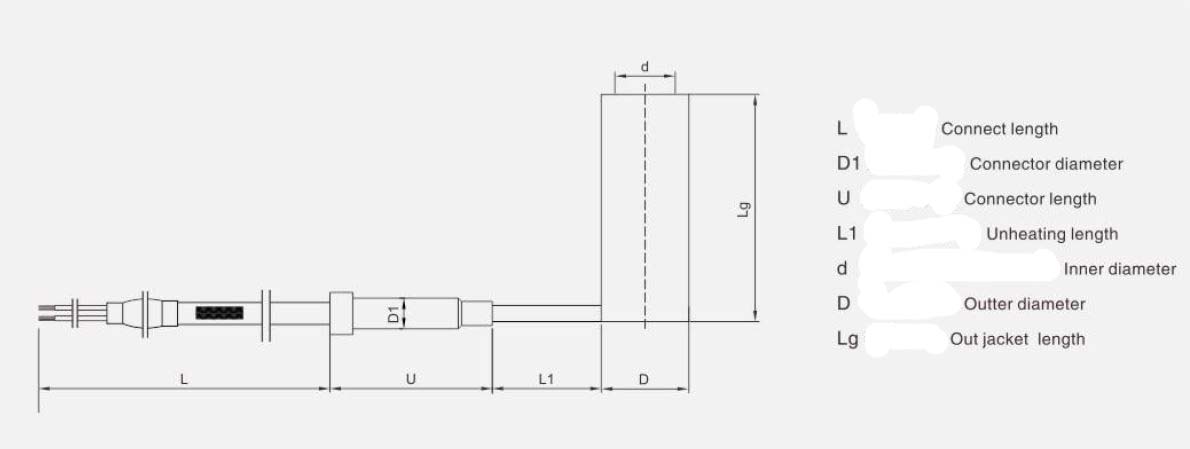

Technical Drawing

3. Feature

4. Application