Dongguan Ampfort Electronics Co., Ltd. |

|

Verified Suppliers

|

|

Disc Zinc Oxide Chip Varistor 05D471K 470V 500A 0.1W With CQC UL TUV Certificates

Description Of The Chip Varistor 05D471K

chip varistor 05D471K designed as standard UL1449 and IEC61051, for linear LED application, insulated coating and high surge type can withstand inrush surge current , replace dip varistor , tape in reel package, produced by automatic machines, cheaper and easy to be installed.

Features Of The Chip Varistor 05D471K

* Wide operating temperature -40~+125C

* Tape in reel package

* Compact design

* Certificated by CQC UL TUV

* Surface mount devices

* Fully automatic production line

Applciation Of The Chip Varistor 05D471K

* AC LED

* DOB

* LED Driver

* Power Supply

* Floodlight

* LED Lighting

Intellectual Property Of The Chip Varistor 05D471K

| Intellectual property | Appearance patent | ZL 2017 3 0466542.2 |

| Utility patent | ZL 2017 2 0473501.0 | |

| Ivention patent | ZL 2017 1 0297717.0 | |

| International PCT patent | USA | 16666291 |

| Europe | CN2017/118998 | |

| India | 57563 |

Agency Approvals Of The Chip Varistor 05D471K

| Certification | CHINA | CQC | GB/T10193-1997 | 05D:CQC18001202949 10D:CQC18001203056 |

| USA/Canada | UL | UL1449 | E481249-20180122 | |

| Germany (EU) | TUV | IEC61051 | B 094255 0002 Rev.00 | |

| ROHS | SGS/SVHC | SGS is updated annually SVHC is effective for a long time | 05DSGS:CANEC2121716202 07DSGS:CANEC2121716204 10DSGS:CANEC2121716206 SVHC:CANEC2200885702 |

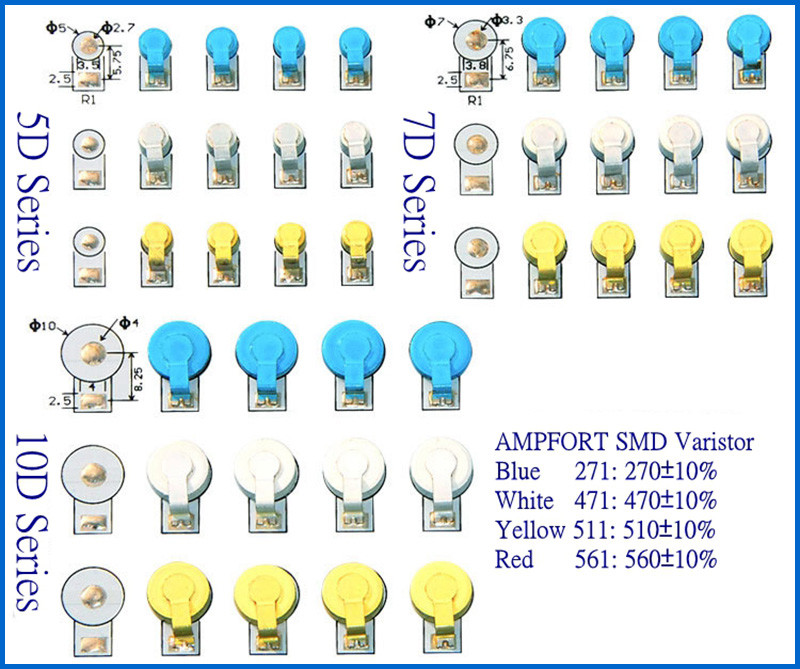

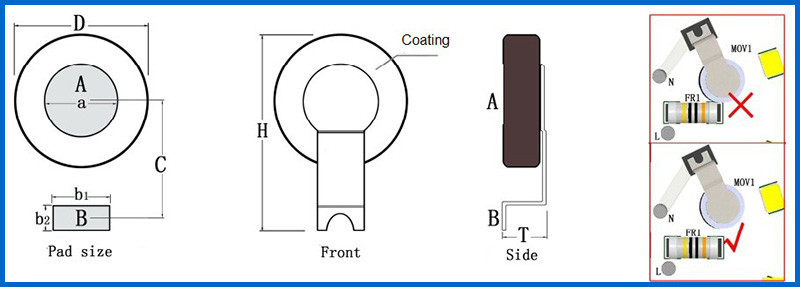

Dimensions, Appearance Identification and Packaging Of The Chip Varistor 05D471K(mm)

Highly Recommended:

1. In the drawing board, it is recommended that the A solder joint

be used as the L line, the B solder joint

as the N line, and the copper skin connected to the B solder joint is routed around the pressure-sensitive

chip circle (the entire diameter D should be regarded as belonging to the A solder joint.

2. For the sake of safety arcing, the circular edge of the chip should be at least 2.5mm away from any other

conductive device, as shown in the figure above (in order to prevent mutual displacement with other devices

during patching, if the space allows, please reserve the larger the

interval is. Okay.)

3. The use of varistors in DC circuits has unfavorable factors. It

is not recommended to use varistors in

rectified DC circuits. Please consider carefully or contact our company at 18128566098 (sales1@ampfort.net),

thank you!

| Model JYVDR~ | Pad A | Pad B | Pad center distance C | Diameter D | Height H±1.0 | Thickness T | Coating material and remarks (insulating paint) | |

| Φa | b1 | b2 | ||||||

| 05D271 | 2.7 | 3.5 | 2.5 | 5.75 | 5.0 | 9.1 | 2.0 | Blue 271:270VDC±10%; White 471:470VDC±10%; Yellow 511:510VDC±10%; Red 561:560VDC±10% 15 inch reel tape(MPQ): |

| 05D471 05D511 | 3.0 | |||||||

| 07D271 | 3.3 | 3.8 | 2.5 | 6.75 | 7.0 | 11.1 | 2.0 | |

| 07D471 07D511 07D561 | 3.0 | |||||||

| 10D271 | 4.0 | 4.0 | 2.5 | 8.25 | 10.0 | 14.2 | 2.0 | |

| 10D471 10D511 10D561 | 3.0 | |||||||

| 05D 07D 10D All series use 15-inch reel and 24-inch feeder placement machine | ||||||||

Electrical Performance Of The Chip Varistor 05D471K

| Model JYVDR~ | Varistor Voltage | Max Allowable Voltage | Max Clamp Voltage(8/20us) | Max Energy | Max Static Power | Capacitance | Leakage Current | Approved Temperature | ||

| VDC | VAC | VDC | VDC | IP | Combined wave(A) | W | pF | (℃) | ||

| 05D271 | 270±10% | 170 | 220 | 480 | 8A | 500A(1000V) | 0.1 | 100 | ≤20uA | -40~125 |

| 05D471 | 470±10% | 300 | 380 | 810 | 10A | 65 | ||||

| 05D511 | 510±10% | 325 | 415 | 870 | 60 | |||||

| 07D271 | 270±10% | 170 | 220 | 450 | 15A | 1.0KA(2000V) | 0.25 | 170 | ||

| 07D471 | 470±10% | 300 | 380 | 770 | 20A | 115 | ||||

| 07D511 | 510±10% | 325 | 415 | 840 | 110 | |||||

| 07D561 | 560±10% | 350 | 450 | 925 | 100 | |||||

| 10D271 | 270±10% | 170 | 220 | 450 | 35A | 2.0KA(4000V) | 0.4 | 380 | ||

| 10D471 | 470±10% | 300 | 380 | 760 | 40A | 250 | ||||

| 10D511 | 510±10% | 325 | 415 | 835 | 230 | |||||

| 10D561 | 560±10% | 350 | 450 | 920 | 210 | |||||

For different voltage application environments, we recommend the following pressure sensitive

combinations to provide overvoltage, surge and lightning stroke protection for ACLED.

| Working Voltage Environment | Forestage Varistor Parameter | Back-end Varistor Parameter | Remarks |

| 110VAC±20% | 270VDC±10% | / | In view of the insufficient voltage withstand capability of the IC, the two-stage varistor can be upgraded to 4KV lightning protection. The user can choose the varistor size according to the requirements of the anti-surge level. |

| 220-230VAC±20% | 510VDC±10% | 470VDC±10% | |

| 240VAC±20% | 560VDC±10% | 510VDC±10% | The combination is recommended for users in Indian and Brazil. |

Since pressure sensitive resistor is easy to degrade under the environment with strong voltage fluctuation,

it is required to select the combination with high pressure sensitive voltage value as much as possible

under the premise that withstand voltage of IC (MOS tube) +lamp bead on lamp board is pretty high

and that voltage has a large fluctuation area; besides, it is

necessary to select pressure sensitive

resistor with large circulation and volume as far as possible,

without exceeding cost limit.

Acceptance Standard Of The Chip Varistor 05D471K

Sampling should follow GB2828-87 and this Specification.

| Item | IL | AQL |

| Appearance, Dimension and Logo | II | 0.65 |

| Varistor voltage | II | 0.65 |

| Capacitance | S-3 | 0.65 |

| Weldability | S-3 | 2.5 |

Using Environment Condition Of The Chip Varistor 05D471K

| Environment Temperature | -40~125℃ |

| Relative Humidity | ≤95% |

| Atmospheric Pressure | 86~106Kpa |

| Vibration Frequency | 10~50HZ |

| Acceleration | 98m/S² |

| Storage Temperature | -40~85℃ |

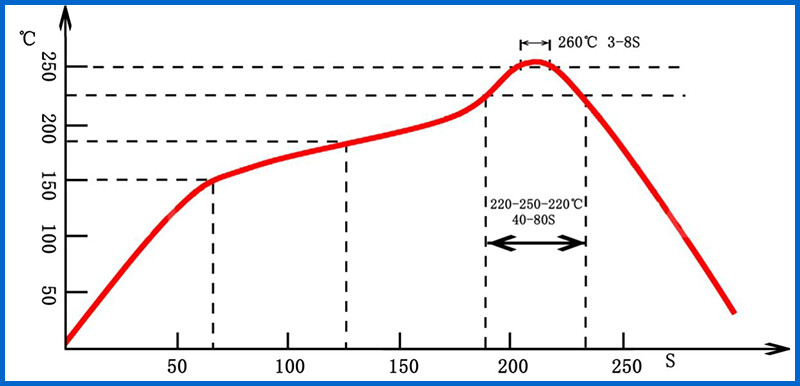

Curve diagram of wave soldering Of The Chip Varistor 05D471K

The picture above shows the approximate trend of the reflow oven temperature curve on the market. Our

SMD pressure sensor uses the silver electrode of the ceramic body as one of the welding electrodes.

Please pay attention to setting the oven temperature and time (if the highest temperature is 260°C,

please Note that the time is 3-8S, if it exceeds 30S, the protection effect of the varistor will be affected).

Other Properties Of The Chip Varistor 05D471K

| Item | Technical Requirement | Testing Condition and Method |

| Appearance | No obvious bubble, pinhole and other defects; no any visible damage lowering using performance; clear and long-lasting sign | Visual inspection |

| Weldability | Tin is uniform in tin immersion part; tinned area is ≥90%. | Soak varistor into 235℃±5℃ tin soldering liquid for 2±0.5 s; then

take it out and observe its appearance. |

| Resistance to Soldering Heat | Change rate of varistor voltage before and after test is ≤±5%. | Soak wire of varistor into 350℃ ±10℃tin soldering liquid, with soak depth for 2-0.5 mm far away from pedestal. Adopt 1.5±0.2 mm thermal insulation layer and keep it for 5±0.5 s; measure varistor voltage with recovery time within 1 h-2 h. |

| High Temperature Load | Before and after test, change rate of varistor voltage is ≤±10%; change rate of limiting voltage ≤±20%. | Put varistor in 125±2℃ for 1,000 h and apply corresponding

allowable using AC pressure of the temperature; power on for 90 min and power off for 30 min. After taking varistor out, put it under normal temperature for more than 1 h; measure varistor voltage and limiting voltage within 4 h. |

| Terminal strength | Change rate of varistor voltage before and after test is ≤±5%. | Apply tension to outlet terminal axis and make it act in sample

main body direction; apply 10N load for 10 s. |

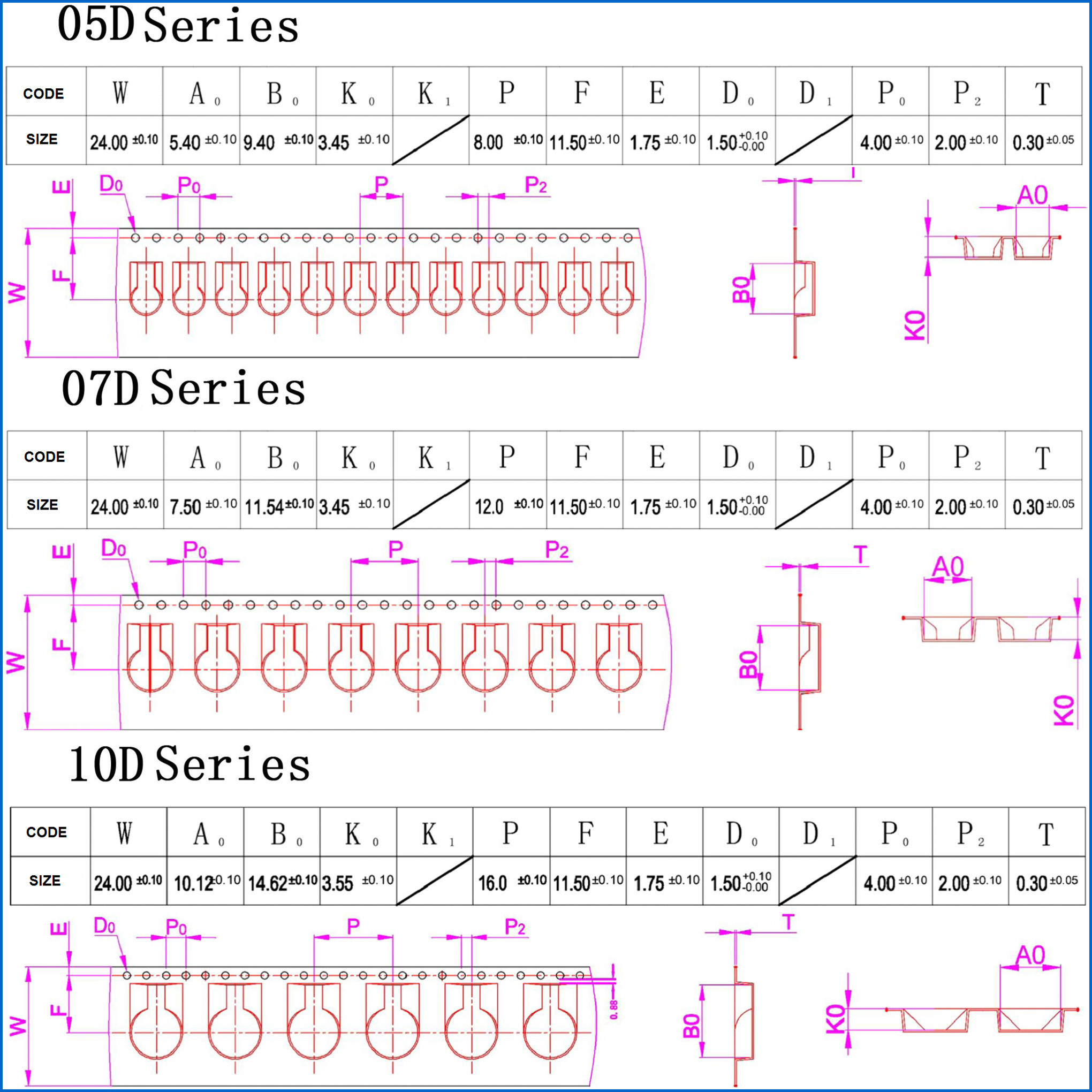

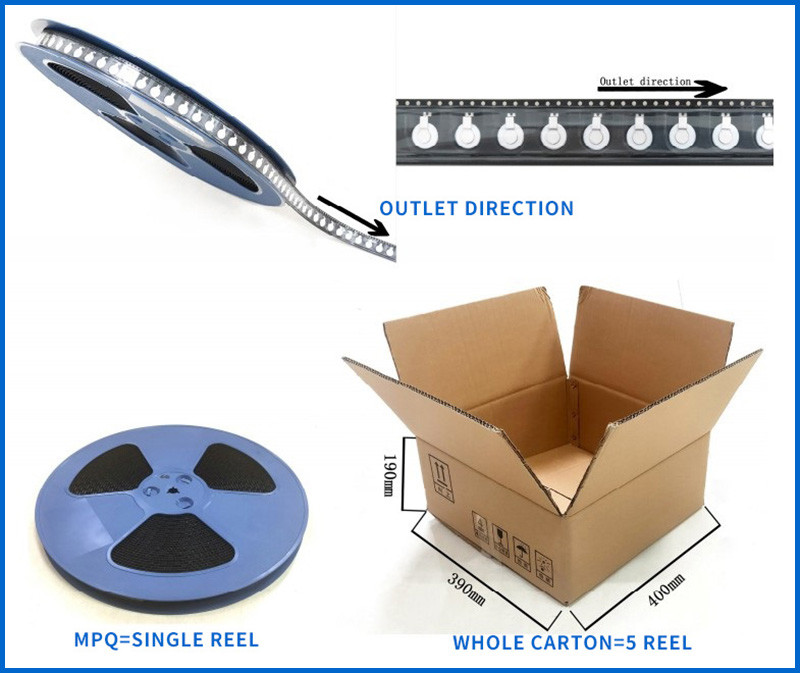

Package Of The Chip Varistor 05D471K

Precautions

1. The cumulative error of any 10 consecutive ratchet holes does

not exceed ±0.2mm;

2. The non-parallel distance of 250mm in the length direction of

the carrier tape shall not exceed 1mm;

3. The uninjected R angle is 0.2-0.3, and the uninjected demoulding

slope is 5°;

4. Comply with EIA-481-D specification and ROHS requirements;

5. Thickness: 0.30±0.05mm;

6. The whole series of 05D 07D 10D adopts 15-inch reel and 24-inch

feeder placement machine.

| Model JYVDR~ | MPQ (QTY/REEL) (PIECES) | WEIGHT/REEL(KG) | QTY PER REEL(PIECES) | WEIGHT PER CARTON(KG) |

| 05D271 | 4000 | 1.5 | 20000 | 8 |

| 05D471 | 3000 | 1.5 | 15000 | 8.4 |

| 05D511 | 3000 | 1.5 | 15000 | 8.4 |

| 07D271 | 3000 | 1.8 | 15000 | 9.5 |

| 07D471 | 2000 | 1.7 | 10000 | 9.1 |

| 07D511 | 2000 | 1.7 | 10000 | 9.1 |

| 07D561 | 2000 | 1.7 | 10000 | 9.1 |

| 10D271 | 2000 | 2 | 10000 | 11 |

| 10D471 | 1500 | 2.2 | 7500 | 12 |

| 10D511 | 1500 | 2.2 | 7500 | 12 |

| 10D561 | 1500 | 2.2 | 7500 | 12 |

Appendix I: Form of VI Characteristic Curve Of The Chip Varistor 05D471K

Current(A) Voltage(V) Model | 10-3 | 10-2 | 10-1 | 100 | 101 | 102 | 103 |

| 05D271 | 270 | 330 | 380 | 420 | 490 | 580 | / |

| 05D471 | 470 | 580 | 640 | 720 | 840 | 1020 | / |

| 05D511 | 510 | 640 | 700 | 780 | 900 | 1120 | / |

| 05D561 | 560 | 700 | 740 | 800 | 950 | 1200 | / |

| 07D271 | 270 | 320 | 370 | 390 | 440 | 520 | 720 |

| 07D471 | 470 | 560 | 620 | 670 | 760 | 900 | 1100 |

| 07D511 | 510 | 620 | 680 | 720 | 820 | 960 | 1250 |

| 07D561 | 560 | 660 | 700 | 740 | 850 | 1050 | 1290 |

| 10D271 | 270 | 310 | 360 | 380 | 430 | 500 | 640 |

| 10D471 | 470 | 540 | 600 | 650 | 740 | 820 | 1050 |

| 10D511 | 510 | 600 | 650 | 700 | 790 | 880 | 1190 |

| 10D561 | 560 | 610 | 660 | 710 | 830 | 930 | 1260 |

Appendix II: Form of Pulse Derating Curve Of The Chip Varistor 05D471K

| Specificati on/Model | Pulse Width | 50us | 100us | 500us | |||||||||

| Current | 5A | 10A | 50A | 100A | 5A | 10A | 50A | 100A | 5A | 10A | 50A | 100A | |

| 05D | Times | 104 | 102 | X | X | 102 | 10 | X | X | 10 | X | X | X |

| 07D | 106 | 104 | 2 | X | 105 | 103 | X | X | 102 | 2 | X | X | |

| 10D | ∞ | ∞ | 103 | 10 | ∞ | 105 | 102 | 2 | 106 | 103 | 1 | X | |

| 14D | ∞ | ∞ | 104 | 103 | ∞ | 106 | 103 | 102 | 106 | 104 | 2 | 1 | |

| 20D | ∞ | ∞ | 105 | 104 | ∞ | ∞ | 104 | 103 | ∞ | 106 | 103 | 101 | |