Dongguan Ziitek Electronic Materials & Technology Ltd. |

|

Verified Suppliers

|

|

Non toxic 1.5W / mK epoxy adhesive paste Thermal Conductive Glue 4000 CPs 300 volts/m For Automotive Starters Potting

Company Profile

With a wide range, good quality, reasonable prices and stylish designs, Ziitek thermal conductive interface materials are extensively used in Mainboards, VGA cards, Notebooks, DDR&DDR2 products, CD-ROM ,LCD TV, PDP products, Server Power products, Down lamps, Spotlights, Street lamps, Daylight lamps, LED Server Power products and others.

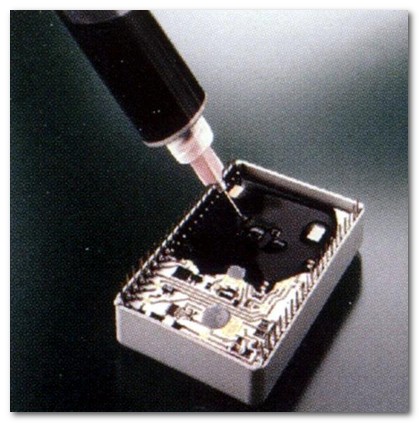

TIE™ 280-15AB is a two compound, high thermal conductive, low temperature cured, long pot life, fire resistant epoxy encapsulant compound. It is design for potting of capacitors and electrical devices.

Features

> Good thermal conductive: 1.5W/mK

> Excellent insulation and smoothly sourface.

> Low shrinkage

> Low viscosity, expediting air releaseed.

> Excellent in solvents and water proof.

> Longer life time.

> Excellent thermal shock efficiecy and impact resistance

Application

> Automotive starters potting; General potting Thermal detector potting

> Ferrite adhesion; TIP type LED; Good adhesion to aromatic polyester

> Relay sealant; Good adhesion to rubber, ceramics PCB and plastics

> Power transformers and coils; Potting capacitors Potting of small electrical devices

> Adhesion to metal glass and plastic LCD & substrates adhesion; Coating and sealant; Coil ; IGBTS; Transformer; Fire retardant

> Optical / medical component adhesive

| Typical Uncured Material TIE™ 280-25A (Resin) | |

| Color | Black |

| Viscosity@25℃ Brookfield | 3,000 cPs |

| Specific Gravity | 2.1 g/cc |

| Shelf life @25℃ in sealed container | 12 months |

| TIE™ 280-25B (Hardener) | |

| Color | Black |

| Viscosity@25℃ Brookfield | 5,000 cPs |

| Shelf life @25℃ in sealed container | 12 months n |

| Mix Ratio (By weight) TIE™ 280-12A : TIE™ 280-12B = 100 : 100 | |

| Viscosity @25℃ | 4,000 cPs |

| Working pot life (250 g @25℃) | 45 min |

| Specific Gravity | 2.1g/ccn |

| Cure Schedule | |

| Cure 12 hours at 25℃ | |

| Cure 30 minutes at 70℃ | |

| Cured Properties | |

| Hardness @25℃ | 85 Shore D |

| Service temperature | -40℃ to +130℃ |

| Glass transition temperature Tg | 92℃ |

| Elongation | 0.10% |

| Coefficient of thermal expansion, / ℃ | 3.0 X 10-5 |

| Fire resistance UL | Meet 94 V-0 |

| Moisture absorption % wt gain 24 hours water immersion @25℃ | 0.1 |

| Thermal | |

| Thermal Conductivity | 1.5 W/m-K |

| Thermal Impedance @10psi | 0.31 ℃-in²/W |

| ELECTRICAL AS CURED | |

| Dielectric Strength | 300 volts / mil |

| Dielectric Constant | 4.2 MHz |

| Dissipation factor | 0.029 MHz |

| Volume resistivity, ohm-cm @ 25℃ | 3.0 X 1012 |

Why Choose us ?

1.Our value message is'' Do it right the First time, total quality control''.

2.Our core competencies is thermal conductive interface materials

3.Competitive advantage products.

4.Condidentiality agreement Bussiness Secrect Contract

5.Free sample offer

6.Quality assurance contract

Ziitek Culture

Quality :

Do it right the first time, total quality control

Effectiveness:

Work precisely and thoroughly for effectiveness

Service:

Quick response, On time delivery and Excellent service

Team work:

Complete teamwork, including sales team, Marketing team, engineering team, R&D team, Manufacturing team, logistics team. All is for supporting and servicing a satisfy service for customers.