Suzhou Polywell Engineering Plastics Co.,Ltd |

|

Verified Suppliers

|

|

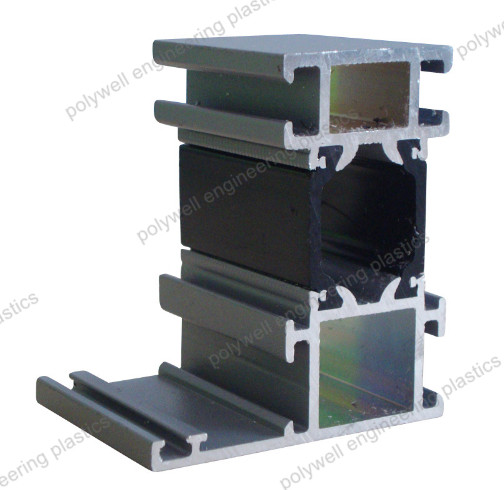

1. Pre-extruded profiles made from polyamide with 25 percent glass-fiber

2. Locked in place in ‘pockets’ extruded into two separate (inner and outer) aluminum extrusions

3. Enables finished assemblies with different finishes and colors on each surface

4. Aluminum extrusion pockets need to be ‘knurled’ prior to insertion of the polyamide profiles-and ‘rolled’ to create a structurally-secure finished assembly

5. The polyamide profiles can be supplied with ‘sealing-wire’ which give a reliable seal and enhanced shear strength when activated by heat e.g.-powder coating

6. The aluminum extrusions can be finished either before or after installation of the polyamide strips

Adding a thermal break to a window or door prevents both heat and cold from transferring through the frames altogether, alleviating issues that might be caused by extreme environments. By controlling this transfer, thermally broken windows and doors improve energy efficiency.

Aluminium window has the disadvantage of limited thermal insulation. Its Uf value, which indicates the amount of heat that passes through a window profile, is simply too high. If your windows have standard aluminium profiles, your home may develop condensation, or even mould. Besides the resulting high repair costs, household mould also aggravates respiratory problems such as asthma.

But that disadvantage has now been completely eliminated if you install polyamide strips in aluminum windows. In fact, thanks to the development of a new invention known as thermal break profiles, aluminium is at least as good as its competitors. In these profiles, produced with specialized machines, a polyamide strip is placed between the inner and outer sections of the profile.

Polyamide is a plastic that insulates more than 500 times better than aluminium, so thermal break profiles have a much lower Uf value - and transmit much less heat or cold. As a result, your home stays warmer in winter, while keeping the heat outside more easily in summer.

Name | Brand | Material |

Nylon Thermal Break Strips | Polywell | PA66 GF25 |

Item | Unit | GB/T 23615.1-2009 | PW-Technical specification |

Density | g/cm3 | 1.3±0.05 | 1.28-1.35 |

Linear expansion coefficient | K-1 | (2.3-3.5)×10-5 | (2.3-3.5)×10-5 |

Vicat softening temperature | ºC | ≥230ºC | ≥233ºC |

Melting point | ºC | ≥240 | ≥240 |

Testing for tensile cracks | - | No cracks | No cracks |

Shore hardness | - | 80±5 | 80-85 |

Impact strength(Unnotched) | KJ/m2 | ≥35 | ≥38 |

Tensile strength(longitudinal) | MPa | ≥80a | ≥82a |

Elasticity modulus | MPa | ≥4500 | ≥4550 |

Elongation at break | % | ≥2.5 | ≥2.6 |

Tensile strength(transverse) | MPa | ≥70a | ≥70a |

High temperature tensile strength(transverse) | MPa | ≥45a | ≥47a |

Low temperature tensile strength(transverse) | MPa | ≥80a | ≥81a |

Water resistance tensile strength(transverse) | MPa | ≥35a | ≥35a |

Aging resistance tensile strength(transverse) | MPa | ≥50a | ≥50a |

1. Sample water content less than 0.2% by weight.

2. Norm laboratory condition:(23±2)ºC and (50±10)% relative

humidity.

3. The specifications marked with "a" only applies to I-shape strip

otherwise, the specifications concluded between supplier and buyer

through consultation, shall be written in contract or purchase

order.

Before sales

1. introduce products in detail

2. recommend suitable solutions

3. provide with reference information

During manufacturing

1. provide with layout and engineering conditions

2. inform the processing status

3. offer related documents

After Sales

1. provide installation, commissioning and training

2. offer spare parts

3. Provide with necessary technical support

Related Products

About Sample

Sample is Free, but the express fee is collect or you pay us the cost in advance.

About MOQ

For the polyamide granules, MOQ is 1 ton. For the thermal break strips, MOQ is 5,000 meters.

About Customizing Special shape of polyamide Profiles and its period

You can customize the special shape of polyamide strips. If we didn't meet this shape before, we will make new mold for you, and you should pay for the mold.

About Customizing Package Style and Marks

You can customize the package style and marks.

Why your price is higher/lower than others?

For years specializing in polyamide granules and thermal break strips has bestowed us experienced and skilled technical workers and production workers. We promise the stability of products and the high-quality of raw material. Furthermore, we can provide technical support from raw material to the final appliance. Believe in that you can get better products and service with lower price.

About warranty

We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. . Any quality issue, we will deal with it immediately.

For all specifical shapes, they could be packaged in linear, the length will be 6 meters, or customized.

For the Shape "I", "C", and some simple shapes, they can be packed in rolls. 400-600 meters/roll.

shipped in 10-15 working days after payment.