Suzhou Polywell Engineering Plastics Co.,Ltd |

|

Verified Suppliers

|

|

| Material | PA66GF25 |

| Production Speed | 8-14 cm/min |

| Max Output | 60-80 kg/h |

| Power | 380V,50Hz or customized |

| Water | Tap water or well water |

Extrusion is a technique where molten polymer is forced through a die and is used to produce components of a fixed cross-sectional area such as polyamide thermal break profiles.

The plastic extrusion process begins when PA compounds in the form granules are continuously fed through a hopper into the extruder. The screw gradually moves these materials along the barrel, and in the process, enough heat is generated to melt the PA compounds.

-We can make good quality strips moulds, including the complicated moulds.

Strip quantity from 20-120 pcs.

Strip shape from I type, C type, T type, CT type Hollow type

etc.

-We can supply the whole production line, including raw

material, Parallel twin-screw granulator and the extruding machine

of thermal barrier strip.

Production Time

30-38 working days after receiving the deposit

Payment

50% T/T before production, 50%T/T before shipment

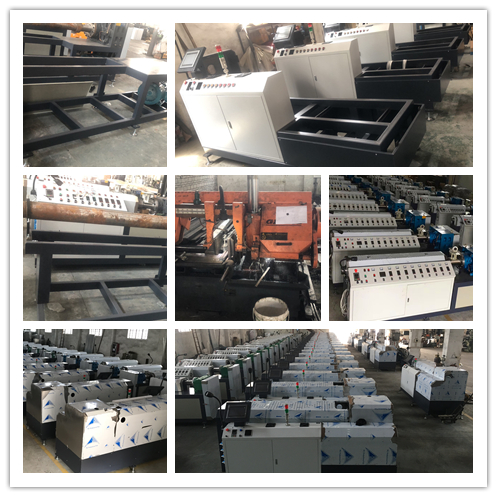

Our Factory

Please feel free to contact us if you have any questions.