Suzhou Polywell Engineering Plastics Co.,Ltd |

|

Verified Suppliers

|

|

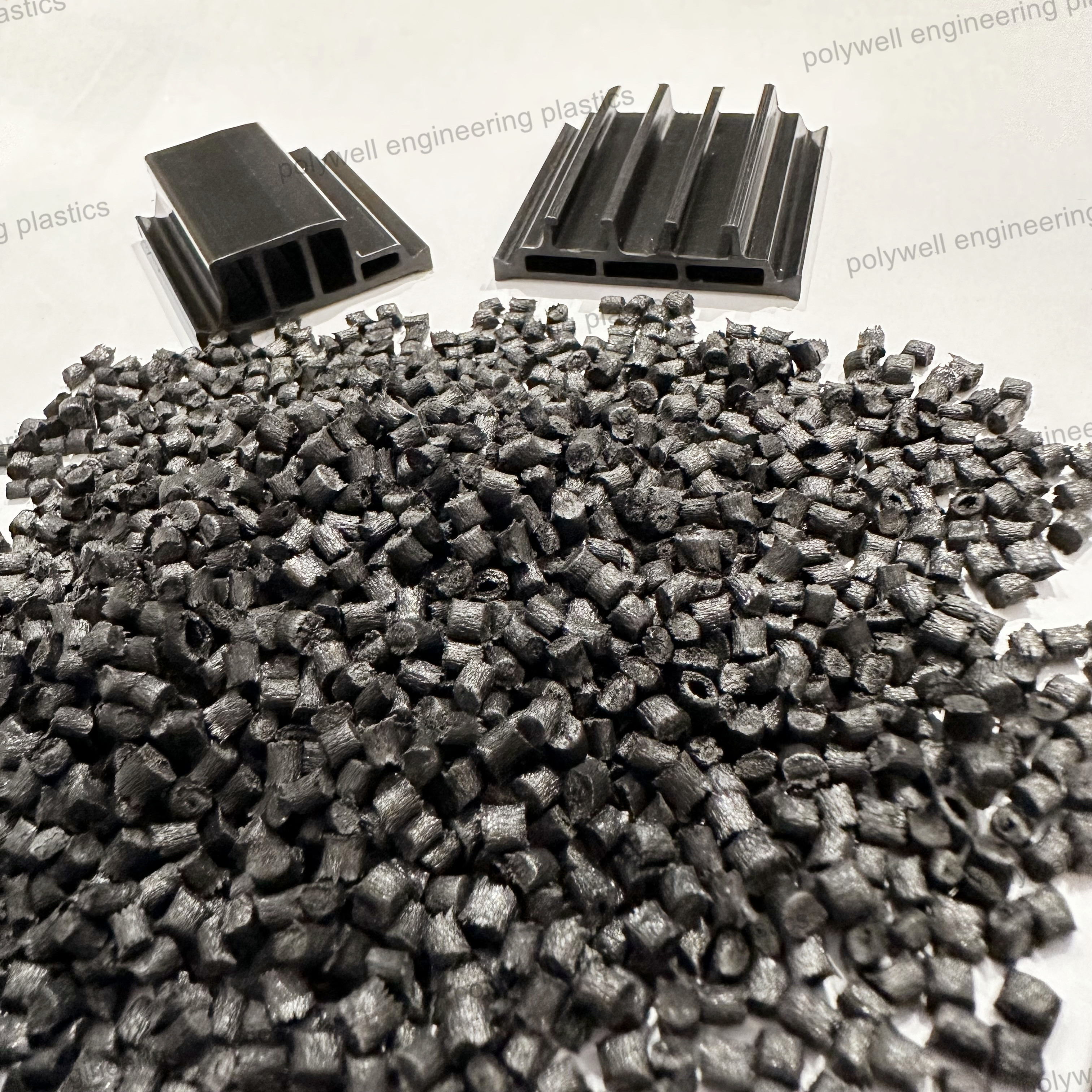

PA66 is copolymerization for extrusion molding. PA66 is safe and

reliable with excellent stability.

The product is based on PA66 resin. It is produced by twin-screw

extruder after adding glass fiber and various additives.

Its characteristics are high mechanical strength, large modulus, good wear resistance, stable size and long-term work at high temperature.

1. It has excellent mechanical properties, high strength, high toughness.

2. The material has excellent coloring ability, can achieve various requirements of color matching

3. The shrinkage rate of PA66 is between 1% and 2%. The addition of glass fiber additives can reduce the shrinkage rate to 0.2%~1%. The shrinkage ratio is large in the flow direction and in the direction perpendicular to the flow direction.

4. PA66 is resistant to many solvents, but is less resistant to acids and other chlorinating agents.

5. PA66 excellent flame retardant performance, by adding different flame retardants can achieve different levels of flame retardant effect.

| NO. | Item | Unit | GB/T 23615.1-2009 | PW-Technical specification |

| Material Properties | ||||

| 1 | Density | g/cm3 | 1.3±0.05 | 1.28-1.35 |

| 2 | Linear expansion coefficient | K-1 | (2.3-3.5)×10-5 | (2.3-3.5)×10-5 |

| 3 | Vicat softening temperature | ºC | ≥230ºC | ≥233ºC |

| 4 | Melting point | ºC | ≥240 | ≥240 |

| 5 | Testing for tensile cracks | - | No cracks | No cracks |

| 6 | Shore hardness | - | 80±5 | 80-85 |

| 7 | Impact strength(Unnotched) | KJ/m2 | ≥35 | ≥38 |

| 8 | Tensile strength(longitudinal) | MPa | ≥80a | ≥82a |

| 9 | Elasticity modulus | MPa | ≥4500 | ≥4550 |

| 10 | Elongation at break | % | ≥2.5 | ≥2.6 |

| 11 | Tensile strength(transverse) | MPa | ≥70a | ≥70a |

| 12 | High temperature tensile strength(transverse) | MPa | ≥45a | ≥47a |

| 13 | Low temperature tensile strength(transverse) | MPa | ≥80a | ≥81a |

| 14 | Water resistance tensile strength(transverse) | MPa | ≥35a | ≥35a |

| 15 | Aging resistance tensile strength(transverse) | MPa | ≥50a | ≥50a |

1.Sample water content less than 0.2% by weight.

2.Norm laboratory condition:(23±2)ºC and (50±10)% relative

humidity.

3.The specifications marked with "a" only applies to I-shape strip

otherwise, the specifications concluded between supplier and buyer

through consultation, shall be written in contract or purchase

order.

Packaging details: 25kg/bag

Delivery details: shipped in 5-8 working days after receiving the

payment

Please feel free to contact us if you have any questions.