Infinity Machine International Inc. |

|

Verified Suppliers

|

|

Computer Hydraulic Universal Testing Machine , Hydraulic Testing Equipment

Model: IN-300EC/600EC/1000EC

Purpose:

Computer screen display hydraulic UTM mainly adopts main machine of

underneath-type oil cylinder, worm gear drive, mainly used in

mechanical property test in the way of tensile, compression,

bending and shearing for metal, nonmetal, composite material and

product, etc. And it can also conduct test and data process

according to GB, ISO, JIS, ASTM, DIN and standards user provides.

Widely used for check and analysis on materials in industries

including building construction, metallurgy, aerospace and machine

manufacturing, it is ideal testing equipment for scientific

research institutions, institutions of higher education, industrial

and mining enterprises, technical supervision, arbitration

inspection department and other departments.

Specification:

| Model | IN-300EC | IN-600EC | IN-1000EC |

| Capacity | 300KN (30T) | 600KN (60T) | 1000KN (100T) |

Testing force | 6KN~300KN | 12KN~600KN | 20KN~1000KN |

| Force accuracy | ±1% | ||

| Displacement measurement resolution | 0.01mm | ||

| Deformation testing accuracy | ±0.5% | ||

The Max tensile space(Including stroke of piston) | 800mm | 800mm | 850mm |

| The Max compression pace(Including stroke of piston) | 700mm | 700mm | 750mm |

| Flat sample clamping thickness | 0~15mm | 0~30mm | 0~40mm |

| Flat sample clamping width | 80mm | 80mm | 120mm |

| Clamping diameter of Round specimen (mm) | φ6~φ26 | φ13~φ40 | φ13~φ60 |

| Compression plate | 204mmX204mm | 204mmX204mm | 204mmX204mm |

Support roller space of | 450mm | 450mm | 450mm |

| Width of support roller | 140mm | 140mm | 140mm |

| Piston stroke | 250mm | 250mm | 250mm |

| Diameter of pivot | 30mm | 40mm | 40mm |

| Clamping way | Hydraulic clamping | ||

| Amplifier | Programmable amplifier plug-in mounted inside the PC, | ||

| Dimension | Machine: | Machine: | Machine: |

| Weight | About 2800kg | About 3000kg | About 4500kg |

| Power supply | Three phases AC380V 50Hz or specified by user | ||

Description Schemes:

The main machine adopts underneath type of oil cylinder, tensile space is above the main machine, compression & bending & cutting space is between the lower cross beam and working station.

It adopts transmission mechanism of worm gear traversing movable

cross-beam to adjust test space, so that the drive system and

positioning system are completely separated, geometric center of

loading system is in full accordance with center of force, and also

guaranteeing the coaxiality of upper and lower jaw and the

durability of machine.

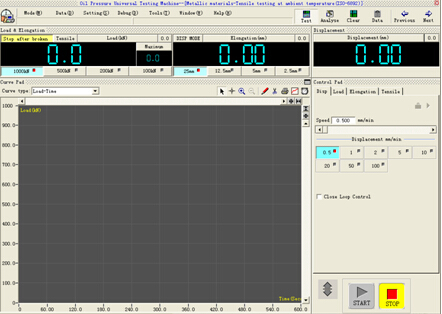

Screen display software:

It conforms to more than 30 relevant regulations of national

standards, like GB228-2002,GB228-2010.

1. Computer control system: it has advantages of high integration level, stable performance and convenient adjustment. Can carry out real-time collection for test data and real-time dynamic display for test characteristics curve; test data file can be saved by the method of Access

common database or SQLserve large database, which is convenient for achieving users’ resource sharing and network management,

and reanalysis.

This software have an easy access to various word2000 reports users defined, solving the problem that different users or one same user

has different requirements for the reports in different times, and it can deal with original data of test force, displacement and time and their

derived curves.

2. Batch test can realize classified display for curve, and curve follows automatically.

3. Monitoring test process: can realize real-time display for various parameters like test force, displacement and curves in the test.

4. Hierarchical management function for software permissions: to improve safety of software and data, this software can realize hierarchical

management function by setting different passwords protection.

5. Result representation function: after finishing and saving test, users can open it at any time in the future and reanalyze test data

according to need.

6. Result contrast function: can observe various test curve at the same time, and can realize Characteristics contrast of specimen to be

analyzed by superposition and fractionated gain of various curves.

7. Force interface: force channel interface and test software can equip all kinds of sensors according to users’ need, and can conduct mark,

parameters modification and normal test.

Basic configuration of system:

Main machine of tester

(Main machine adopts underneath type of oil cylinder, Worm gear drive)

1. Integrated oil source

2.1 High-pressure pump

3. Two-path programmable amplifier, Resolution is 1/300,000

4. High-precision load cell

5. Guyed displacement measurement system

6. Full set attachment grips include: tensile fixture & compression fixture & bending fixture

7. Dedicated control software

8. Lenovo computer

9. HP A4 ink-jet printer

10. Technical data: Operation manual

Our Show Room:

Support and Services:

Technical Support and Services

We are committed to providing our customers with exceptional technical support and services.

We offer a comprehensive range of services to ensure that your product is subjected to rigorous testing and quality control.

Our team of specialists is dedicated to providing the highest quality technical support and services for ourr test machines. If you have any questions or need assistance, please feel free contact us.

Packing and Shipping:

Our test machine will be packed in appropriate cardboard boxes and/or crates. The products will be shipped using standard shipping methods such as air freight, sea freight, or ground transport. Any special shipping requirements should be discussed with the supplier prior to the purchase.

The customer is responsible for all import duties, taxes and/or other fees associated with the goods. The supplier will provide all necessary documentation to facilitate customs clearance.

FAQ:

1. How to choose the most suitable Compression testing machine?

Our professional team will give you the best suggestion as long as you tell us what kind of test you need

to do and the required specification.

2. What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20

working days after deposit receipt. If you are in urgent need, we can consider making special

arrangement for you.

3. Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to

your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Can we visit your factory before order?

Yes, warmly welcome to visit our factory.

5. Do you have customers of our country before?

Now our testing machines have been sold to more than 30 countries, like USA, Canada, Russia,UK,

Italy, Germany, European Union, India, Pakistan, Philippines, Singapore, Thailand and Vietnam,

Iran, Brazil...and so on.

6. How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and

part parts change, necessarily, our engineers may go to your place for better service.

7. How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden carton, it won’t be damaged. We’ve delivered many

testing machines abroad by sea or by air without damage.

8. How to install and use the product?

The product is shipped with an operating instructions and video of English version.