ZHANGJIAGANG FLAME MACHINERY CO.,LTD. |

|

Conventional Rotary Welding Positioners Automatic SKF Slewing Bearing

Quick Details

1. Introduction

Conventional welding positioners are designed for maximum loads of 100KG to 2,000KG have universal applications in the manual and automatic welding of circumferential seams and in the accurate positioning of work-pieces, and extensively applied in pressure vessel, metallurgy, power, chemical industry, metal structure and others lines.

We also provide tailor-made welding positioners according to your special requirements.

2. Main Parameters

Model | HB1 | HB3 | HB6 | HB12 | HB20 |

Max loading KGs | 100 | 300 | 600 | 1,200 | 2,000 |

Rated eccentricity mm | 100 | 150 | 150 | 200 | 250 |

Rated center of gravity mm | 150 | 200 | 250 | 250 | 300 |

Worktable diameter mm | Φ400 | Φ600 | Φ800 | Φ1000 | Φ1200 |

Tilt angle | 0°~120° | 0°~120° | 0°~120° | 0°~120° | 0°~120° |

Rotation speed rpm | 0.1—1 | 0.1—1 | 0.1—1 | 0.1—1 | 0.09—0.9 |

Tilt speed rpm | 2 | 0.9 | 0.8 | 0.5 | 0.4 |

Rotation motor power KW | 0.06 | 0.37 | 0.37 | 0.75 | 1.1 |

Tilt motor power KW | 0.18 | 0.37 | 0.55 | 1.1 | 1.5 |

Max rotation diameter of work-piece in 90° mm | 600 | 1000 | 1500 | 1570 | 1900 |

Earthing Amperes A | 1000 | 1000 | 1000 | 1000 | 1000 |

Main frame length mm | 740 | 930 | 1200 | 1400 | 1700 |

Main frame height mm | 420 | 700 | 900 | 1000 | 1200 |

Main frame width mm | 527 | 820 | 800 | 1000 | 1200 |

Power supply | 380V 50HZ 3P or tailor made | ||||

Above are our standard models and parameters, and it can be designed and manufactured on request. | |||||

*We reserve the right to alter specifications without prior notice.

3. Main features

The standard models of our conventional rotary welding positioners have the following features:

Optional features:

4. Supply range

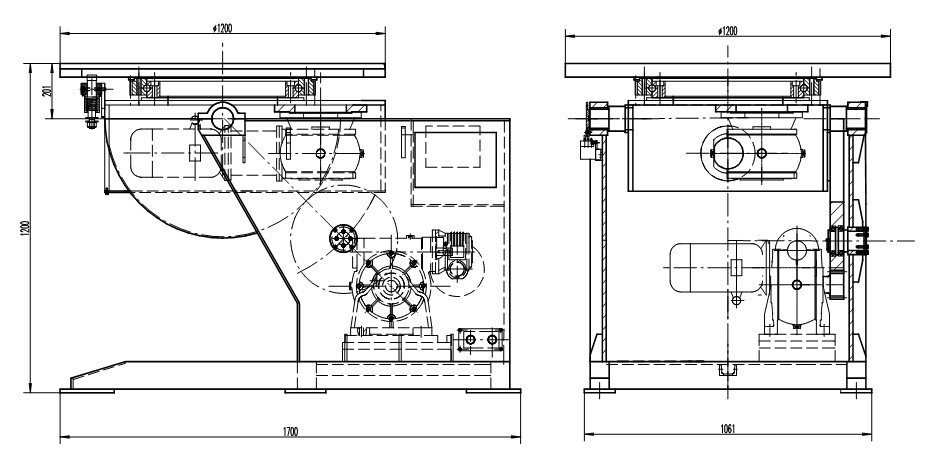

5. Reference drawing

6. Reference photo

7. Comparative advantage