ZHANGJIAGANG FLAME MACHINERY CO.,LTD. |

|

Plasma CNC Flame Cutting Machine Hypertherm EDGE Pro / Micro EDGE

Quick Details

1. Introduction:

Developed and designed in-house and tested in practice, we have produced a series of cutting machines and cutting lines that will be regarded as industry leading since 2003. All of our CNC cutting machines can be equipped with oxy-fuel and/or plasma cutting equipment.

CNC-CG series is our standard cutting machine which not only can cut different profiles/shapes but also can cut strip/straight plate.

Guoheng earned its global market position by offering extremely innovative cutting solutions for customers in steel construction, offshore, shipbuilding, process and crane building industry.

We also provide user-friendly broad choices and options that allow you to configure your CNC cutting system with the capacities, speed and accuracy of your needs.

2. Main Parameters

Model | CNC-CG3000 | CNC-CG4000 | CNC-CG5000 | CNC-CG6000 | CNC-CG7000 | CNC-CG8000 |

Drive system | Single side gear and rack driving | Double sides gear and rack driving | ||||

Rail span mm | 3,000 | 4,000 | 5000 | 6000 | 7000 | 8000 |

Valid working width mm | 2,200 | 3,200 | 4200 | 5200 | 6200 | 7200 |

Strip/straight cutting width mm | 80—2,200 | 80—3200 | 80—4200 | 80—5200 | 80—6200 | 80—7200 |

CNC flame torch | 2 groups | |||||

Strip/straight cutting torch | 9 groups | |||||

Rail length mm | 15,000 (valid cutting length 12,5000), fine machining I-rail | |||||

Torch lift stroke mm | 150 | |||||

Flame cutting speed mm/min | 50—1,000 (setting as per cutting technology) | |||||

Fast return speed mm/min | 4,000 | |||||

Flame cutting material | MS | |||||

Flame cutting thickness mm | 6—150 (single torch), piercing thickness≤100 | |||||

Cutting surface roughness | Ra12.5-25 | |||||

Positioning accuracy mm/m | ±0.5 | |||||

Intersection point deviation mm | ≤0.5 (800*800 industry standard prescribed figure lineation) | |||||

Diagonal error mm | ≤0.5 (square lineation) | |||||

Power supply | AC220V 50HZ single phase | |||||

Above are our standard models and parameters, and it can be designed and manufactured on request. | ||||||

3. Main features

The standard models of our CNC flame/strip oxy-fuel cutting machines have the following features:

Optional features:

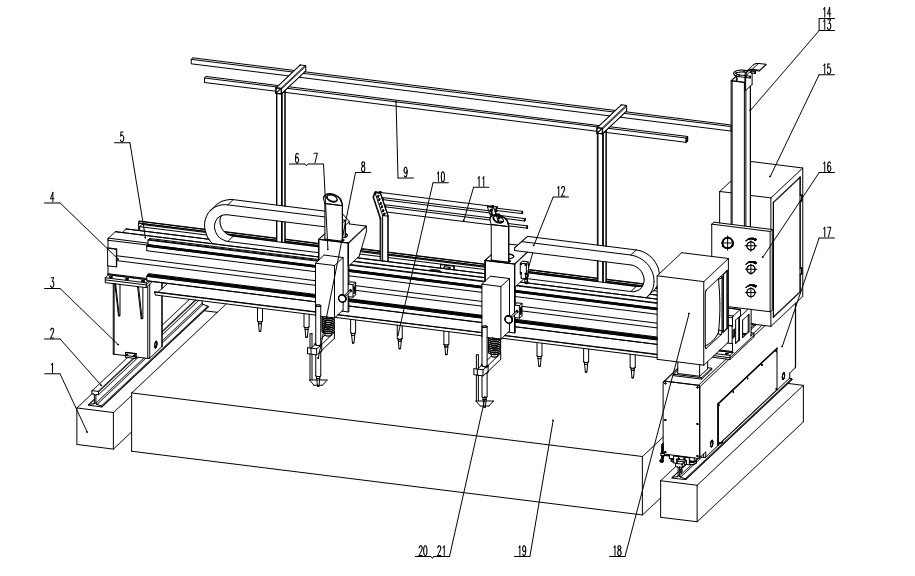

4. Reference drawing

5. Reference photo

6. Comparative advantage