ZHANGJIAGANG FLAME MACHINERY CO.,LTD. |

|

SAW Welding Manipulator Turntable and Roller - beds for Wind Tower

Quick Details

1. Introduction

The promotion of renewable “green” energy has recently been stepped up by quite a number of governments. There is no question that the genuine cost of producing wind electricity is far higher at present than that of the electricity generated by non-renewable energy sources like fossil and nuclear energy. This energy segment is expected to experience extremely powerful trends in the years to come.

We can supply a complete solution for this wind mill production—from material cutting, inner and outer longitudinal welding, fit-up process, flange welding to sand blasting and painting. If you have any similar project, please contact us freely. It’s our pleasure to present our technical paper and plan drawing.

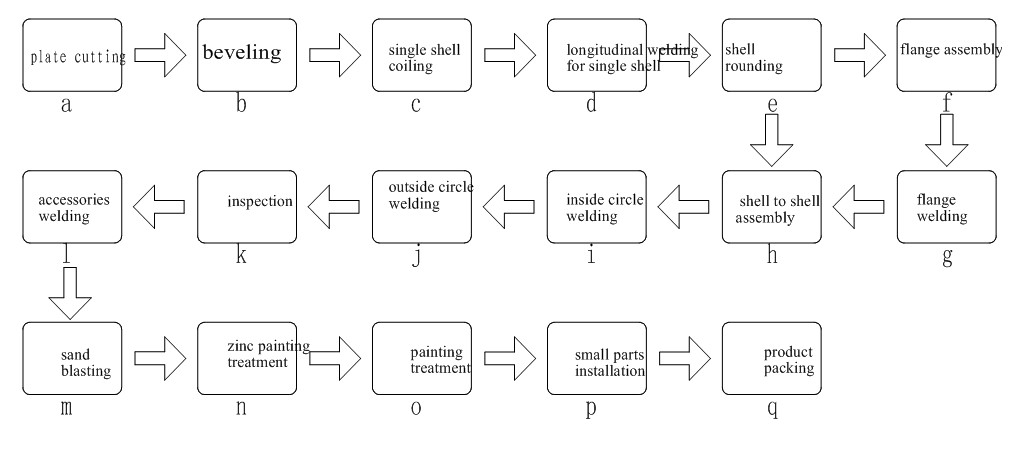

2. Work flows

3. Machines required

Depends on different requirements and material specifications, we will make the special design for you. All or some of the above mentioned machines maybe required.

5. Reference photo

6. Comparative advantage