Shenzhen SMTfly Electronic Equipment Manufactory Ltd |

|

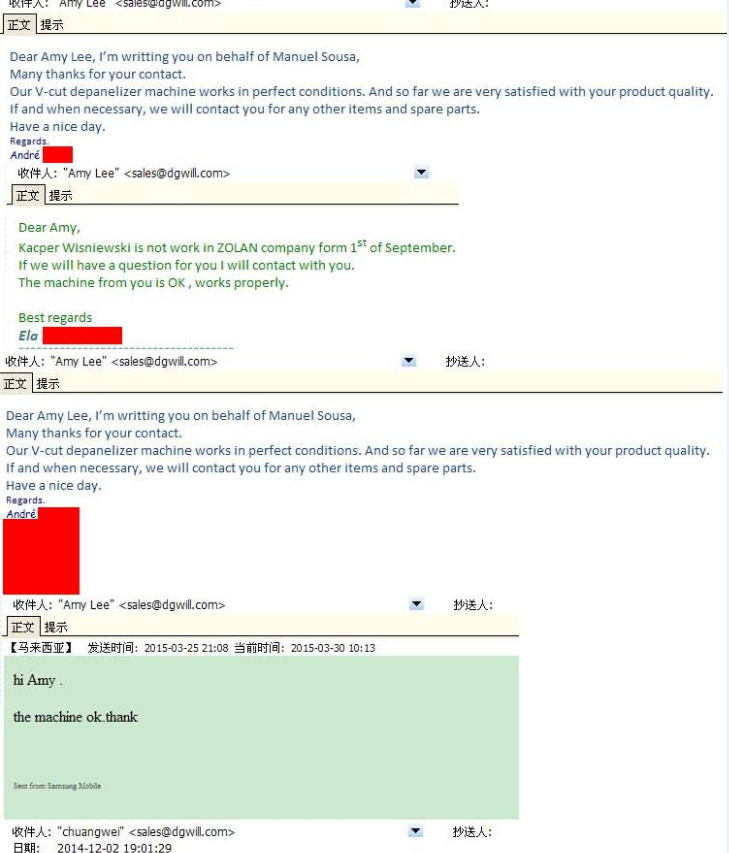

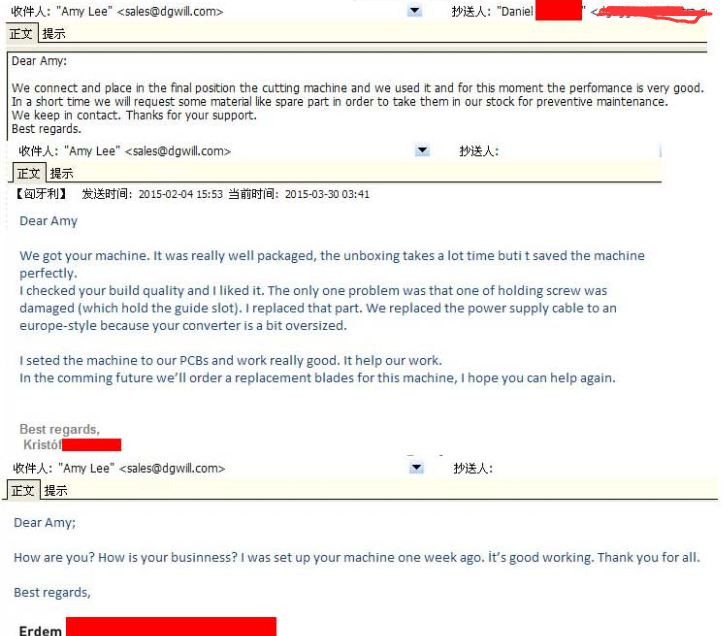

Customer Feedback

Microprocessor-based controller provides precise and consistent

temperature control.

Unique pulsed heat thermode offers uniform temperature

distribution, fast heating and cool-down.

Flexible programmable profiles for targeted idle, preheat and

reflow temperature.

Floating thermode and digital pressure control.

Manual shuttle of work; optional pneumatic shuttle.

NEW: Bonder machine uses conductive adhesive film (ACF) for

very fine pitch devices.

CW can supply fixtures and thermodes ,thermocouple

"Smarttherm" constant heat-type machine for heat seal applications

Optional CCD camera system and monitor

Thermode Specifications

Maximum Thermode Area 400 mm²

Maximum Thermode Length 100 mm (normal)

Force Range 30 N @ 0.09 MPa to 600 N @ 0.6 MPa

Thermode Stroke 50 mm

Force Accuracy ±

Actuation Type Pneumatic

Pulsed Heat Control Specifications

Temperature Range 1° C Interval

Idle 0 to 150° C

Preheat 0 to 500° C

Reflow 0 to 500° C

Time Periods 1 Second Interval

Preheat 0 to 200 Seconds

Reflow 0 to 200 Seconds

Heating Rate Control Eight (8) Selections

Programmable Heat Profiles Four (4) Internal

Memory

Thermode Cooling Air For Cooling Thermode

SmarTherm HSM

Compressed Air: 4 to 6 Bar

Vacuum Flow Rate: 24L/min Maximum

Electrical Power: 220 or 110 Vac (Factory Preset)

Weight: Net - 91Kg, Gross 159Kg

Customer list:

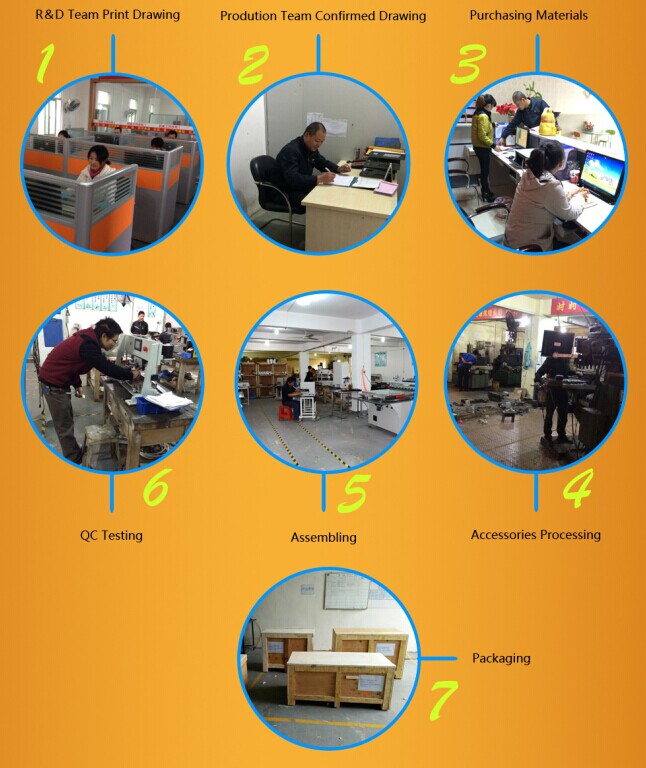

Production process;

Our service:

1. Engineers available to service machinery oversea

Engineers are available to be sent to freign countries to do

machinery training and offer technical support.

2. Mature technique & forerunner to process makes high quality

machinery

As largest manufactory in South China, we have 12 years experience

on PCB separator machines and soldering machines.Our R&D team

continuously upgrade the existing machines to meet the market

development trend.

3. Effective customer service

All of us together are stronger and wiser than any one of us

individually. To succeed, we must assume responsibility, cooperate

with fellow associates and withdepartments, effectively comminicate

with one another, foster enthusiam and participate in

decision-making. To be seay reachable by customers and provide

prompt replies to solve their problems and create value for

customers.

4. One year warranty for the machines except accessories

Robust frame construction and Japanese steel blades obtained good appraise and recognized by and oversea clients. We offer parts for replacement under warranty free of charge, clients only need to bear freight charge.

Our mission:

Ongoing PCB industry PCB separator technological innovation, to create greater value, allowing customers to success

Our Vision:

PCB industry to become the world's leading solution providers PCB separator