Shenzhen SMTfly Electronic Equipment Manufactory Ltd |

|

Best Selling Pcb Routere Machine With Dust Collector CW-F01

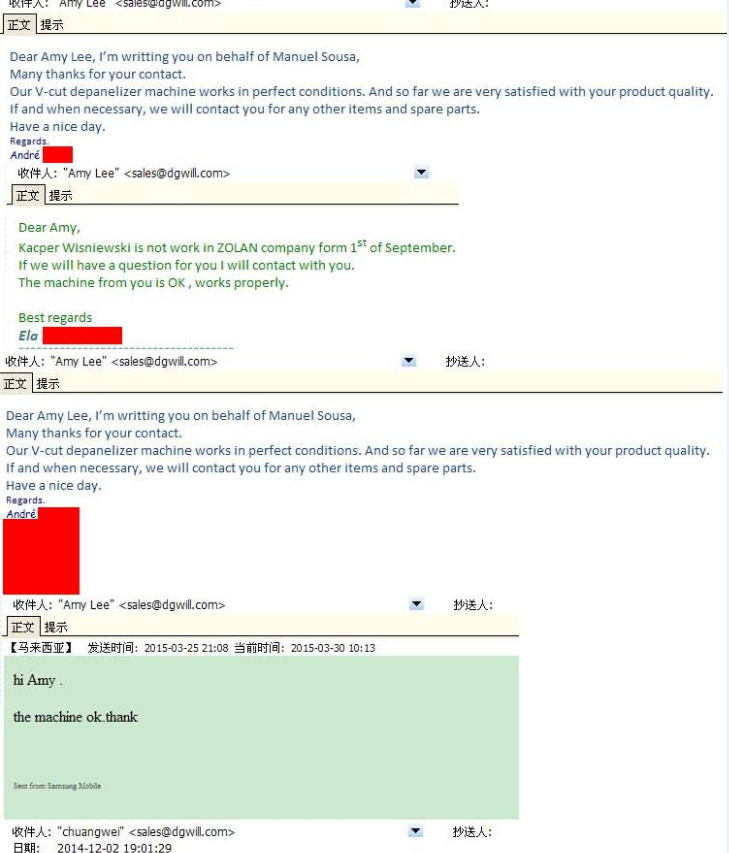

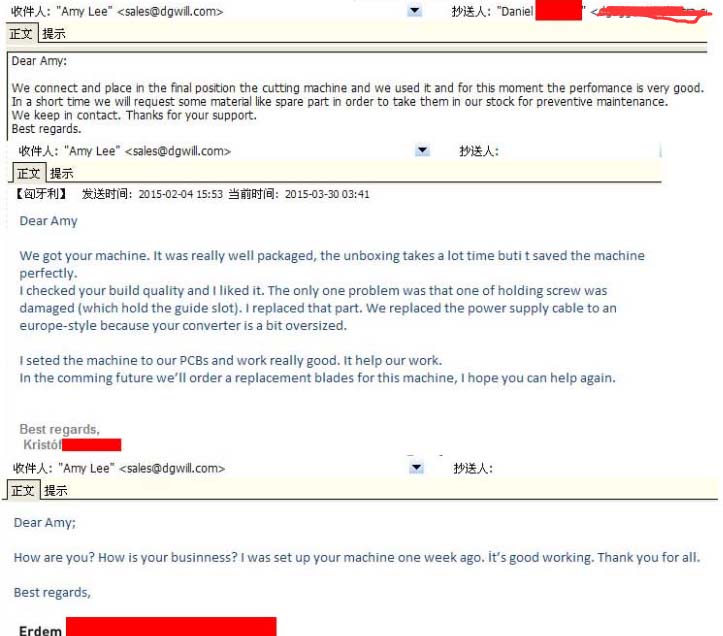

Customers Feedback

CW-F01 profile:

CW-F01 automatic visual cutting machine is the latest designed

high-tech product of a new generation, with (Machine

Vision)automatic visual identification and correction function,

applied by high-accuracy Panasonic servo drive system to realize

quick and precise positioning, rendering accuracy at 0.001mm

maximum to ensure the high quality of the cutting and high

productivity.

Specification:

CW-F01 Software:

Control system | Windows XP Professional (Service3,v.3244) |

Operation GUI | Chinese Windows XP |

Program edit | Inline |

Vision system | CCD AOTU offset |

Control system | F 1.0.2 version |

Hardware:

SPINDLE Morning Star spindle and inverter

CCD | Sony 520 line industrial cameras |

LENS | Computar EX2C |

Screw | TBI Precision ground ball screw imports |

Guide | HIWIN widening Imported linear guide rail |

MOTOR | JiaBao LCF Series |

I/O CONTRONL CARD | HFC PCI-9074 |

DRIVER CONTRONL CARD | HFC PCI-9074 |

I/O CARD | PCI-9074-64pcs/-38pcs |

Static cleanup | STATIC-ST401A Series |

Computer | RMC-8401/6113LP4/300ATX/8651VNA/P4 2.8G 2CPU(S)/1G DDR/80G |

Machine interface | AOC LCD17",Logitech mouse |

Performance Parameters

Overall | |

Dimensions(W*D*H) | 1220mm*1450mm*1420mm |

Weight | 550KG |

Height offset | 60~110mm |

Manipulator | |

Motor type | JiaBao series |

Positioning repeatability | 0.001mm |

Axis working area(max) | 680mm*360mm*50mm |

Work station | |

Work station | standard,specialization |

PCB loading/unloading | manual |

PCB size (max) | 322mm*322mm |

PCB thick (max) | 5mm |

Fixturing | |

Rigidity fixturing | standard |

Fixturing fixation | machinery |

Spindle Motor | |

Power | 400W |

Spindle | 50000rpm/min |

Protect | self/wind cooling |

Change cutter | Specialization |

Routing capability | |

Cutting speed(max.) | 100mm/s |

Driving speed(max.) | 3000mm/s |

Precision of cutting | 0.01mm |

Vacuum System | |

Vacuum power | 2.2KW AC 380V |

Vacuum plumb | |

Utilities | |

Power | 2.2KW AC380V |

Air supply | 2~5KG/cm2 |

Features and functions

1. Smooth cutting finish only by router cutting .

2. There is little distortion on PCB during cutting because using high-frequency spindle motor . It is 1 / 10 of pressing , 1 / 100 of breaking by hand .

3. One-touch program changeover .

4. Able to cut liner and arc with router machine , diminish the restriction on PCB design .

5. Read QR code or JIG BIT auto select cutting program , or check accordance between cutting program and JIG .

6 , Powerful Dust Collection minimized dust adhesion on PCB .

7 , Developed high performance router bit that expanded bit life

and relief littering .

8 , Cut down PCB cost because need not making V-groove on PCB

9 , Cut down running cost because without mold

CW-F01 is a machine cutting multi-panel PCB according to the pre-edited path by use of high-speed motion of milling cutter. Getting rid of the cutting flaws of manual cutting, C-CUT or Push cut, it improves product quality and reduces scrap rates.

The machine adopts human-machine interface vie Windows XP, which is simple and convenient, able to achieve automatic cutting path correction, edit and modification of high-pixel CCD program, block program and single-step program.

The PCB with two interactive plates loading and unloading materials will effectively reduce machine idle time, thus achieve an ideal productivity. With a high-pixel CCD amplification lens, auxiliary demonstration program and editing function, the machine can work more accurately and get sharper graphics. Equipped with automatical mark positioning correction system, the motion path is displayed in real time and traced in an analog way; all in all realize a clear vision.

Due to the automatic position correction function, PCB can cut more accurately. Within the maximum 3mm, the machine can correct the deviated position automatically, therefore lowers the standard for operators to place the plate, in this way to improve work efficiency immensely.

The copy function of the two plates, the block, arrays, multi-angle plate, the single tracing modification function and block editing function indeed simplify the process of programming and increase efficiency.

Vacuum cleaner made of imported high-power fan and the 10V high voltage static eliminator makes less noise and can vacuum better. The monitor for tooling will extend the life span of the milling cutter, as the blade will rise and fall to the uncut position upon finished the previous cut and the risingand falling distance and times can be set based on the length of the blade.

CE certification:

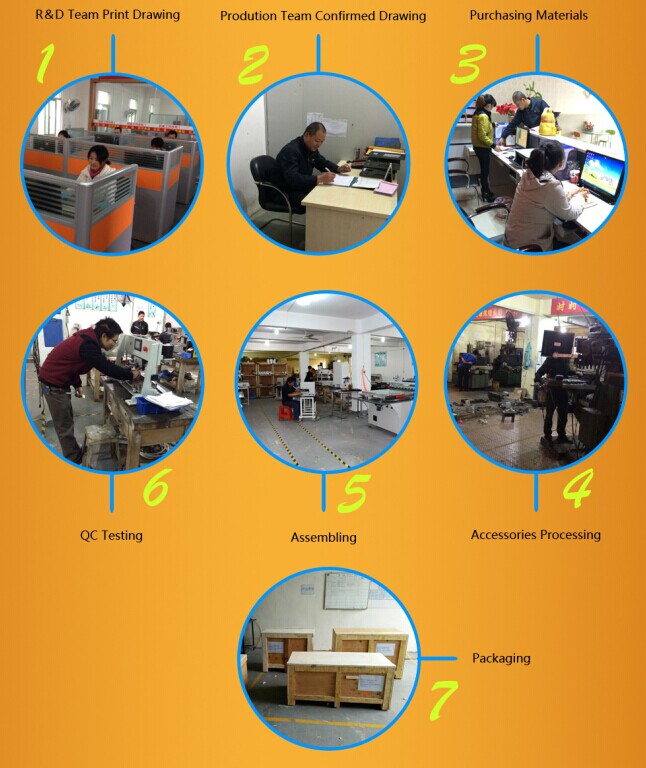

Production flow:

Cooperative clients: