Shenzhen SMTfly Electronic Equipment Manufactory Ltd |

|

Automatic Cnc Laser Pcb Labeling Machine With High Precision CWDB-1A

Labeling processng

step 1. pick up labels according to points

Step 2. CCD correction Angle according to label position

step 3. label to the correct position

Automatic assembly implementation and processing

supply material method:

our factory supply label,three ways of pcb feeding:

(1)connect production line (2)loader/unloader machine (3)Manual

Characteristics

1. The machine conforms to the IEC standard, the complete closed to

complete a homework assignment, availability

2. Using two‐dimensional platform and visual inspect system

instantly take, arbitrary coordinate movement to realize high speed

automatic code.Code were varied, qr code, one‐dimension code, can

be Numbers, letters, special symbols, etc.

3. 17 inch computer monitor, operator could observe the PCB print status at any time.Includes loader and unloader machine, realize automatic PCB labeling, could print QR code, one‐dimensional code, numbers, letters, special symbols and other species.

Composition and parameters

Hardware:

Screw Guide | HWIN import linear Screw Guide |

leadscrew | HWIN import grinding leadscrew |

Motor | PansomicMINS‐A5T/YIXINservo drive |

motion control card | HFC PCI9014 |

adapter card | HT‐B01 |

LCD |

Software:

control system | Independent R&D servo drive system |

Program | online |

Features:

1. Configuring high‐pixel CCD zoom lens, an auxiliary program

Teach‐camera editing function, higher precision and more accurate,

clearer images. Easy to edit & modify block programs and

single‐step program.

2. Intelligent control, automatic correction MARK point positioning

systems, mobile real‐time display and analog path trace route,

display a glance, automatic alignment correction, higher labeling

accuracy.

3. Simple adjustment, adjust label position freely for 10 setting

positions. It is simple to change different PCBs to save time.

4. Flexible application can pick off the production or assembly

line production, production site layout is simple.

5. Powerful, has fault alarm function, production counting

function, parameter setting protection function, convenient

production

and management.

6. Transparent cover design, emergency button could avoid accident

to ensure safe operating.

operating principle:

Core principle: sensors detect the product after, back to the

signal to the labeling control system, the signal after the

PLC processing, at the appropriate time to send out the tag

attached to the product set position, product flows through the

device,

tags coating is firm, a label attached

operating process:

Operation: put a PCB (could connect production line) ‐‐> PCB

feeding(automatically) ‐‐> product correction (automatically)

‐‐>

product testing (automatically) ‐ >Labeling (automatically)

‐‐> finish PCBs collection

Specification parameter:

CCD | F‐130F series industrial camera |

lens | Computar EX2C |

laser head | import from japan |

guide rail | TBI import grinding leadscrew X,Y two each,X450mm,Y520mm |

servo motor | A5 motor series |

I/O control card | ADLINK PCI‐9074 |

motion control card | ADLINK PCI‐9074 |

adapter card | BOXIN‐BO1 |

Static Eliminator | STATIC‐ST401A series |

Industrial control host | Industrial control host(RMC‐8404/6113LP4/300ATX/8651VNA/P4 |

Display | DEL liquid crystal LCD17" displayer and Logitech mouse/Duble Swallow mouse |

2.software | |

control system | WINdowsxp |

operation interface | GUI |

program | online |

visual system | Pixel computational precision CCD visual orientation correction

system( |

control software | F1.0.2 official |

Dimension | 600mm*600mm*1180mm |

weight | 100kg |

Foot adjustable height | 60~110mm |

Manipulator | |

motor type | Panasonic A5 motor series |

control motor repeat accuracy | 0.01mm |

The axis maximum working range | 400mm*400mm |

Work station | |

transmitt | Workbench automatic feeder,leadscrew transmission |

max size | 400mm*400mm |

edit mode | online programming |

Program storage | select the storage location According to the need |

collocate program CCD | computar Series high pixel color CCD |

Operation Monitors | |

tri‐color light | High brightness trichromatic lamp monitoring machine of all kinds

of |

The motor overheat detection | Overheating, overload, low voltage protection function |

Servo overload detection | With overload, circuit is normal and low voltage protection function |

print counter | pcb type, print numbers,diverse counting way. |

Machine error record | software automatic memory machine all alarm record |

Ⅲ.Accuracy | |

Laser head position accuracy | 0.01mm |

print precision | 0.01mm |

Ⅳ.Safety | |

scope of work protector | Use all‐direction seal protection way |

door interlock protection sensors | Before and after the safety door safety switch induction(optional) |

Why us

1. Engineers available to service machinery oversea. Engineers are available to be sent to freign countries to do machinery training and offer technical support

|

2. Mature technique & forerunner to process makes high quality machinery. As largest manufactory in South China, we have 12 years experience on PCB separator machines and soldering machines. pcb router Our R&D team continuously upgrade the existing machines to meet the market development trend.

|

3 One year warranty for the machines except accessories. Robust frame construction and Japanese steel blades obtained good appraise and recognized by and oversea clients. We offer parts for replacement under warranty free of charge, clients only need to bear freight charge

|

4. Effective customer service. All of us together are stronger and wiser than any one of us individually. To succeed, we must assume responsibility, cooperate with fellow associates and withdepartments, effectively comminicate with one another, foster enthusiam and participate in decision-making. To be seay reachable by customers and provide prompt replies to solve their problems and create value for customers

|

Our mission Ongoing PCB industry PCB separator technological innovation, to create greater value, allowing customers to success

|

Our Vision: Ongoing PCB industry PCB separator technological innovation, to create greater value, allowing customers to success

|

About us

Dongguan ChuangWei Electronic Equipment Manufactory was founded in 2004,is located in the world manufacturing city Dongguan,Guangdong,China. The company is committed to development,manufacture,sales and service for professional pcb separator/pcb depanelizer electronic equipment machinery. The company has advanced production and processing equipment and an experienced development and manufacture team, half of them have over 10 years experience in electronic equipment industry.

Begin with 2004 the company leader invested to develop and manufacture the PCB separator and PCB depaneling machine. From then on we pay more attention to product quality, safe to use and product innovation, so far we have produced many high quality, stable performance, high cost-effective products. Improve production yields, increase productivity, and thus enhance the market competitiveness of our customers.

Until now we have design different separating PCB types of PCB separator and PCB depaneling machine with manual, motor-driven, pneumatic-driven, mold punching, milling cutter router. Due to the good quality and reasonable price our customers are all over the world. Up to now ChuangWei have became one of the biggest PCB separator production base in China

Company always insists to the "customer needs is our goal, creating most value for customers", strives to provide customers with first-class products, first-class service. So since date established we very attached importance to product quality,continuous improvement for manufacturing process,try hard to save money for customers.

Our great mission is to be the most professional and excellent supplier in the pcb separator/pcb depanelizer electronic equipment industry.

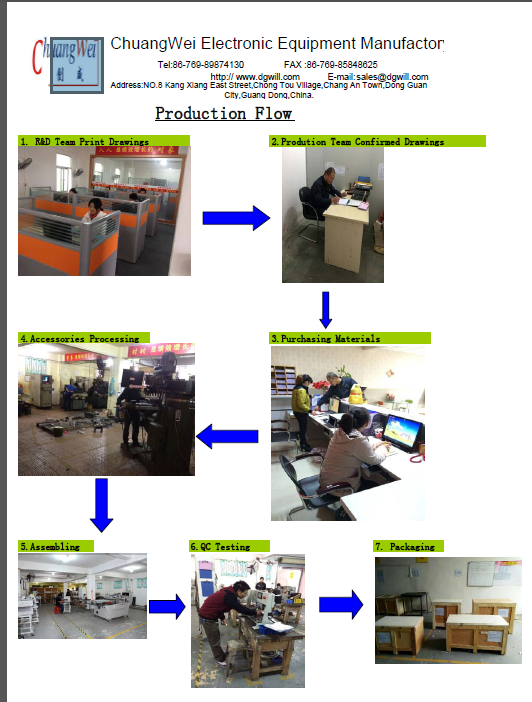

Our production flow

Cooperative clients