Shenzhen SMTfly Electronic Equipment Manufactory Ltd |

|

Pulse Heat Bonding Machine COF TAB ACF Bonding Machine for TV/LCD/LED Screen

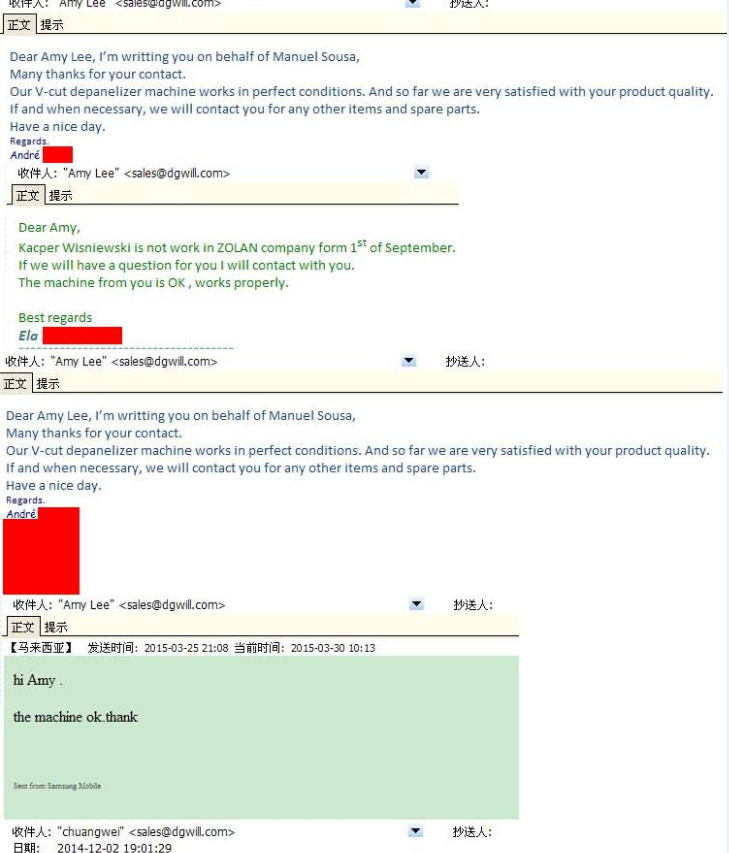

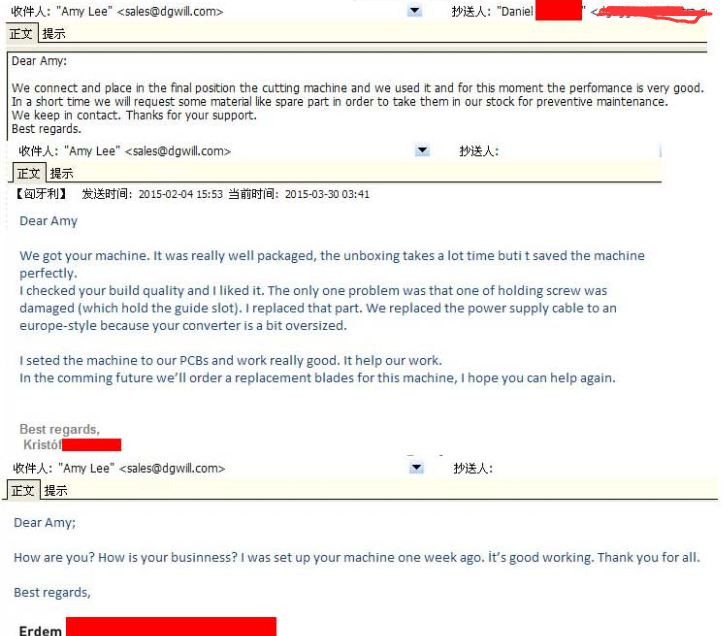

Clients Feedback

Processing customized: yes

Type: Pulse Heat machine, LCD screen repairing machine

Brand: VD

Model: VD-580PS

Power supply: 220V

Other name: LCD screen repairing machine

Use LCD screen repair: TAB binding,

Power: 1.2 KW

Work pressure: 2.0~7.5 (Mpa)

Hot pressing time: can be set (s),

Thermocouple type: K

Machine shape size: 1800 x1200x100 (mm)

The system control is: panasonic - PLC control (single)

Production parameters have store brands on the market are samsung, LG, sharp, chi mei, auo, huaxing photoelectric, Hitachi, hanyu display, Huasheng, Zhonghua etc. Four different temperature set points starting temperature, the temperature of the first paragraph, the second section temperature, cooling temperature.PLC and touch screen communication, can according to production needs to extend the production process automatic control function. System automatically detect, abnormal alarm display function, make the equipment maintenance more quickly.

The stability control is: panasonic - TC2

Imported temperature sensing line and panasonic's newest chips (TC2) make more accurate temperature control, with fast heating time, temperature precision higher characteristic, and add heating curves and parameters of synchronous display.

The operating interface is: WEIVIEW full-color PDA (single communication)

6.5 -inch intelligent man-machine interface, programmable controller (PLC) control system, make the equipment operation is stable and reliable.

Heating method: pulse heating mode

Fast heating/cooling and auxiliary cooling function. High quality titanium alloy head, automatic temperature compensation function, make the temperature more accurately.

High precision counterpoint: micrometer counterpoint

Equipped with advanced optical alignment system, fully satisfy the product clear counterpoint and production of precision, para X, Y, Z axis adjustment adopts high-precision micrometer regulator, slippery course synchronous operation, ensure that para a higher precision.19 inches large screen display contrapuntal line electrode, makes the registration faster, more generous appearance.

The size of the maintenance and brand:

Unlimited size and the screen card TFT LCD, LED screen, TAB, COG and PCB bonding.

Repair the fault:

Vertical, horizontal, vertical, horizontal, black belt, the black line, the color line, ribbons, multi-line, flower screen, black screen, white show, horizontal, vertical half and half, fault, and so on.

CR-680PS models is exclusively to domestic original installed after-sales service and a number of patented products.

Features:

1, PLC control, pulse heating mode, combined with titanium alloy extrusion head, rapid heating and rapid cooling, can be set up four heating, accurate temperature control.

2, 5.7 "color touch screen LCD display input, realizing the temperature curve, according to the Chinese menu, all the parameters set browse concise and straightforward.

3, large load platform, stepper motor drive, multiple IC can be preset position, the platform automatically move the pressure to stay.

4, under the high magnification camera system, ensure that the product clearly counterpoint.

5, powerful software, perfect the system debugging, automatically detect fault and alarm function.

Application: suitable for 12-80inch TFT panel and TAB, FPC and LCD or PCB board combination bonding.

Technical parameters:

power: AC220V±10%, 50Hz, 4500W

work environment: 10~60℃, 40%~ 95%

work pressure: 0.5 ~ 0.7 Mpa

welding stress: 5 ~ 28 KGF

temperature Settings: one to four paragraphs

temperature Settings: RT ~ 399 ℃

hot pressing time: 1 ~ 99 s

hot-pressing precision: pitch 45um

production capacity: 35 s/TAB or COF package

hot pressing head size: MAX 60 x 8 mm

the fuselage size: 1508 mm (L) x 1245 mm (W) x 1483 mm (H)

weight: about 300 kg

More information welcome to contact us:

Email/Skype: s5@smtfly.com

Mobile/Wechat/WhatsApp: +86-136-8490-4990