Guangdong Grand Metal Material Co., Ltd |

|

Verified Suppliers

|

|

bending stainless steel sheet metal Water Ripple hammered metal

plate

Product name | bending stainless steel sheet metal Water Ripple hammered metal

plate |

Standard | JIS, AISI, ASTM, GB, DIN |

Type | Sheet & Plates |

Technique | Cold rolled |

Certification | ISO |

Length | 1200mm Customized |

Width | 2400mm Customized |

Edge | Mill / Slit Edge |

MOQ | 1TON |

Other Model | 200 Series/300 Series/400 Series |

Brand Name | SDtaigang |

Surface Treatment | 2B, BA, NO.1,NO.4,HL,Hairline, No.4, 8K, Mirror Finish etc. |

Material:

This product is made from stainless steel sheet metal, known for its excellent corrosion resistance and durability. Stainless steel is highly suitable for outdoor and humid environments as it is resistant to rust and corrosion.

Bending Process:

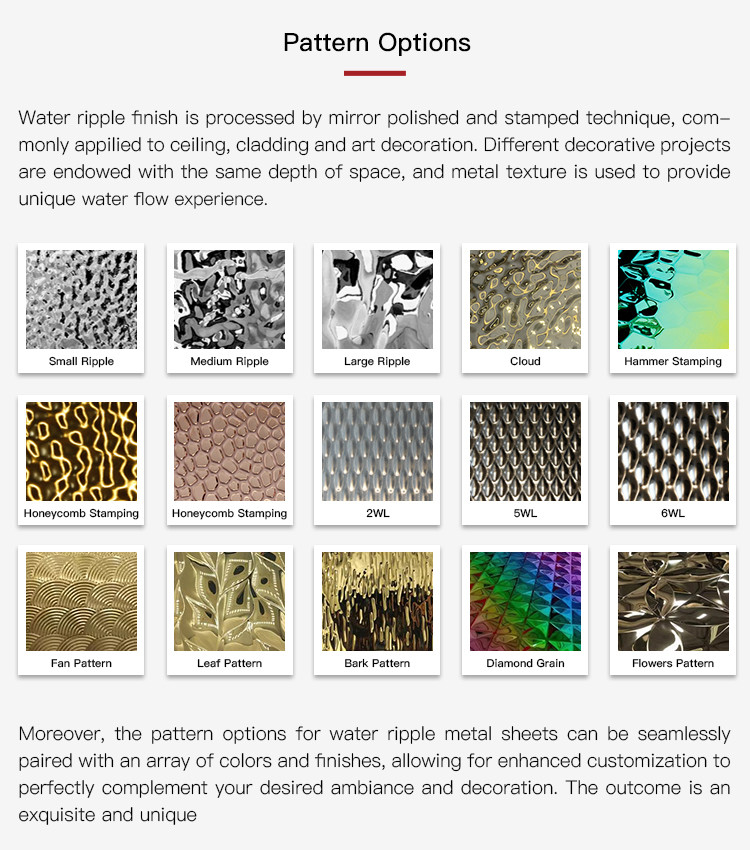

The product's surface is treated with a bending process, creating a design that features water ripple and hammered textures. These textures give the product a unique appearance, resembling water ripples or carefully crafted hammered effects.

Applications:

These bent stainless steel sheets are often used in interior decoration, such as on walls, ceilings, columns, and cabinet surfaces. They can also be used for outdoor decoration, including in landscaping, architectural facades, and courtyard embellishments. Additionally, they are suitable for crafting items like carvings, sculptures, and home decor.

Visual Appeal:

The water ripple and hammered effects impart a distinctive texture and aesthetic to the product. The way these textures reflect light makes the surface look dynamic and lively, making it visually appealing.

Customization Options:

Typically, this product comes in various sizes, thicknesses, and texture styles to meet different customers' needs. Customers can choose the specifications and designs that best suit their projects.

Durability:

Thanks to the characteristics of stainless steel, this product is highly durable and can withstand long-term use without being easily damaged or corroded, making it an ideal choice for many applications.

The range of designs offered for stainless steel sheets with water ripples will pleasantly surprise you. Because Grand Metal offers such a wide selection of distinctive patterns, colors, and finishes, including matte and shiny finishes, you may achieve any desired aesthetic, whether you prefer a sleek, modern, or industrial appearance.

The use of stainless steel water wave pattern

Common stainless steel water wave pattern plates are generally used

for background wall shapes, ceiling decorations, or exterior walls,

which are widely used.

There are usually three ways to install stainless steel water ripples:

1. Staged stabilization of stainless steel plates at the grass -roots base, staggered stabilization stagnation;

2. After the stainless steel processing of the grass -roots plate, welding the fixed angle code on the four sides, and fix it on the shed with a self -attack nail;

3. Dragon welding connects the processing process of stainless steel plates with the composite plate of wind templates in the form of a socket. This is relatively high with the fire prevention level.