Mirror Finish

Mirror finish is created by mechanically treating the surface with

a series of progressively finer abrasives. Alternatively a special

rolling procedure is used which can simulate the appearance of

mechanical abrasion. For this stage, it is essential to remove deep

scratches as any surface defects will be very noticeable on the

finished product. The final process involves buffing the surface

for 5-10 minutes to create a mirror-like, highly reflective finish.

PVD Color

PVD is the abbreviation of Physical Vapor Deposition. It is a

process carried out in high vacuum at temperatures between 150 and

500 .PVD stands for Physical Vapor Deposition, which refers to

under the condition of vacuum, use Physical method to make material

preparation technology of thin film deposited on the plated , A

range of colors are available, including gold, black, bronze, blue

and so on.

| Type | mirror stainless steel sheet |

| Name | mirror finish 300s stainless steel sheet |

| Thickness | 0.5 mm - 3.0 mm |

| Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max.width 1500mm |

| SS Grade | 304,316, 201,430 etc. |

| Finish | Mirror+embossed+color |

| Avaible finishes | No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration,

Sandblast, Combination, lamination etc |

| Avaible color | Gold, Rose gold, Champagne gold, Copper, Bronze, Black, Blue,

Purple, Green etc |

| Origin | POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc. |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

The advantages of mirror polished stainless steel

1. Strong gloss: Because of the mirror effect, the decorative panel is more

beautiful and bright;

2. Strong stain resistance: The surface is very smooth and not easily contaminated with dust,

easy to clean and maintain;

3. Good scratch resistance: Can withstand strong impact and scratches;

4. Good wear resistance: It is more wear-resistant than ordinary steel plates and has a

long service life;

5. Good high temperature resistance: It can be used normally without deformation under the high

temperature of 300 degrees Celsius.

6. Good environmental performance (recyclable): Comply with ROHS standard.

7. Good process performance (can do various complex shapes)

8. There are many kinds of colors

1.Sheets covered with wooden plate for protection in

transportation. 2.All sheets will be loaded in strong wooden packages. 3.Every cartons loaded with good shoring and strengthening. 4.Take container loading pictures and seal the container. 5.Transportation speed is quick. And keep customer each step

informed. |

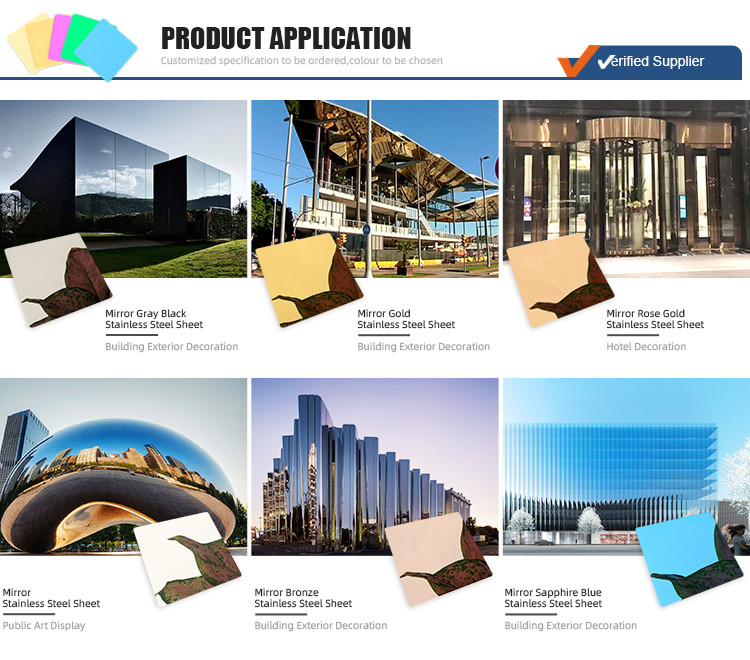

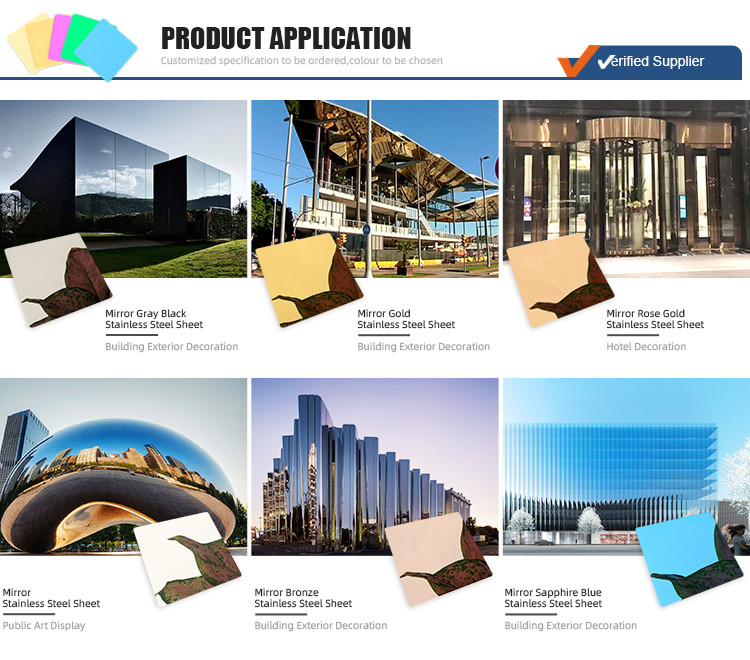

Product Application

1. Chemical industry: Equipment, industrial tanks and etc.

2. Medical instruments: Surgical instruments, surgical implants and

etc.

3. Architectural purpose: Cladding, handrails, elevator,

escalators,door and window fittings, street furniture, structural

sections, enforcement bar, lighting columns, lintels, masonry

supports, interior exterior decoration for building, milk or food

processing facilities and etc.

4. Transportation: Exhaust system, car trim/grilles, road tankers,

ship containers,refuse vehicles and etc.

5. Kitchen Ware: Tableware, kitchen utensil, kitchen ware, kitchen

wall, food trucks, freezers and etc.

6. Oil and Gas: Platform accommodation, cable trays, sub-sea

pipelines and etc.

7. Food and Drink: Catering equipment, brewing, distilling, food

processing and etc.

8. Water: Water and sewage treatment, water tubing, hot water tanks

and etc.

Production process of 8k mirror stainless steel plate

The production process of an 8k mirror stainless steel plate

involves several steps. Here is a general overview of the process:

1. Material Selection: High-quality stainless steel is chosen as the base material for

the plate. Stainless steel alloys such as 304 or 316 are commonly

used due to their corrosion resistance and aesthetic appeal.

2. Surface Cleaning: The stainless steel plate is thoroughly cleaned to remove any

dirt, oil, or contaminants.This can be done through various methods

such as chemical cleaning, mechanical cleaning, or a combination of

both.

3. Grinding: The plate undergoes a grinding process to remove any surface

imperfections, scratches, or irregularities. Initially, coarse

grinding wheels are used to remove larger imperfections, followed

by progressively finer grinding wheels to achieve a smoother

surface.

4. Polishing: After grinding, the plate goes through a series of polishing steps

to achieve a high level of smoothness. Different abrasive

materials, such as polishing belts or pads, are used to gradually

refine the surface. The process typically involves multiple stages

of polishing, starting with coarser abrasives and progressing to

finer ones.

5. Buffing: Once the desired level of smoothness is achieved through

polishing, the plate undergoes buffing. Buffing involves the use of

a soft cloth or pad along with a polishing compound to further

enhance the surface finish and remove any residual imperfections.

6. Cleaning and Inspection: The plate is thoroughly cleaned again to remove any polishing

residues or contaminants. It is then inspected for defects, such as

scratches, dents, or blemishes, to ensure it meets the required

quality standards.

7. Electroplating (Optional): In some cases, an additional electroplating process may be

employed to enhance the mirror-like appearance and durability of

the stainless steel plate. This process involves the deposition of

a thin layer of metal, typically chromium or nickel, onto the

surface of the plate.

8. Final Inspection and Packaging: The finished 8k mirror stainless steel plate undergoes a final

inspection to ensure it meets all specifications and quality

requirements. It is then carefully packaged to protect it during

transportation and storage.

There is a wide range of color options for mirror finish stainless

sheets, which can provide different visual effects for different

requirements.All of them can improve your project with valuable

properties, such as appealing aesthetics, resistance to rust and

corrosion, longevity, and so on. The surface of mirror stainless

steel sheets is finished with BA, 2B polish also known as #8, it

comes with high gloss and reflectivity to bring the interior or

exterior space a unique visual experience.

FAQ

Q1.About us,the relation between factory,manufacture or trader?

A1. Grand metal is a professional production of coldrolled

stainless steel conglomerate , with professional production of

stainless steel experience and our own factory nearly 12

years,where has more than 1,000 professional and technical workers.

we are the foreign trade department of Grand metal. All our goods are dispatched directly from Grand metal mill.

Q2.What are Grand’s main products?

A2.Grand’s main products include 201/304 stainless steel coil and

sheets,all different styles of etched and embossed,surface finished

will be customized.

Q3.How can you ensure the quality of your product?

A3.All products have to go through three checks in the whole

manufacturing process,it includes production,cutting sheets and the

packing.

Q4.What is your delivery time and the supply ability?

A4.The delivery time normally within 15~20working days,we can

supply about 15,000tons every month.

Q5.What kind of equipment in your factory?

A5.Our factory have advanced five-eighth roller rolling,cold

rolling production equipment on the roll,advanced processing and

testing equipment,which makes our product better quality with

efficiency.

Q6.About the complaint,quality problem,etc aftersales service,how

do you handle it?

A6.We will have certain colleague to follow our order accordingly

for each order with professional after-sales service. If any claim

happen, we will take our responsibility and compensate as per

contract. For better serve our client, we'll keep tracing feedback

of our products from clients and that's what make us different from

other suppliers. We're customer care enterprise.