Tianjin Ironstar industry co,.Ltd |

|

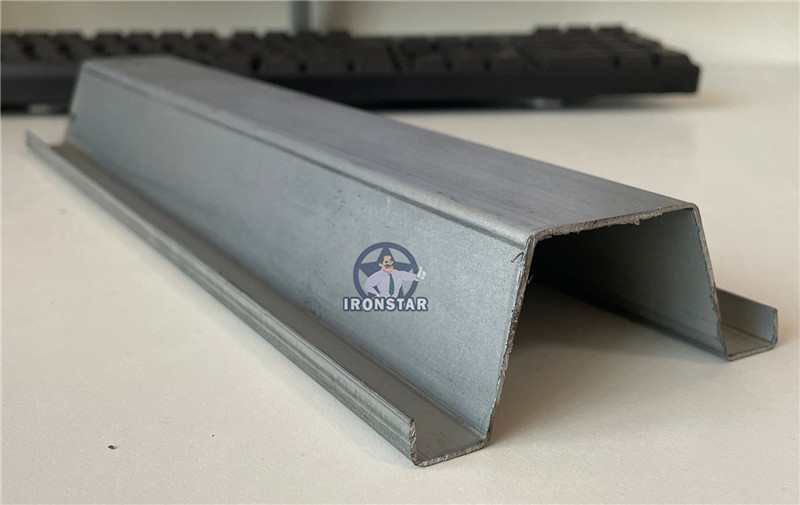

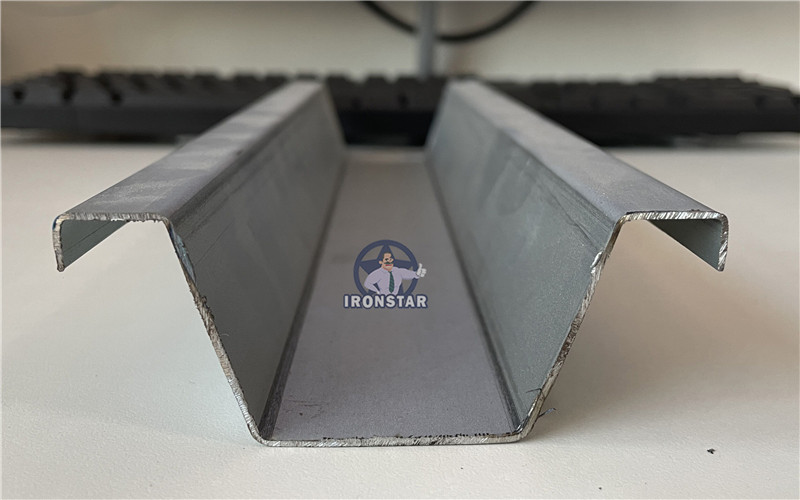

Customized High Speed Ceiling And Drywall 0.3-1mm Metal Sheet Galvanized Omega Profile Hat Channel Roll Forming Machine

Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.8 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

Omega profile roll forming machine | Omega furring channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine

Omega profile roll forming machine popular sell in many countries, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

Product thickness common between 0.3-0.6 mm, it use for Ceiling, work with C channel machine, U channel machine, Angle bead machine and T grid machine

Customized is welcome, tell me your need size and thickness, we provide you satisfied machine

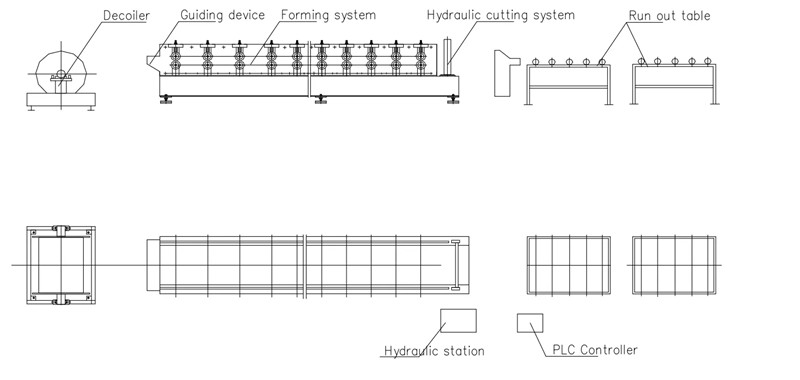

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

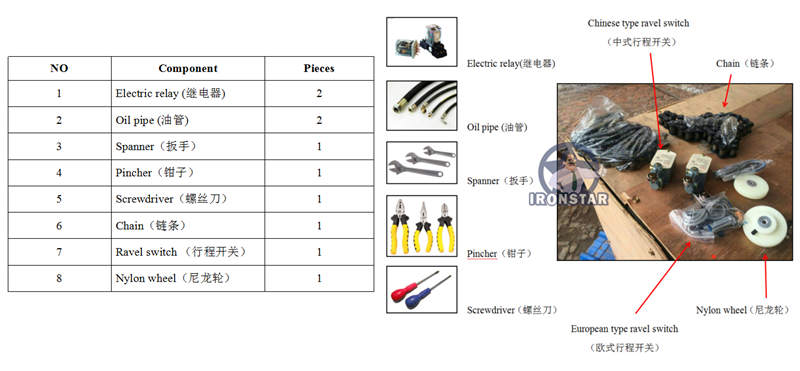

NO | Type | Specification | |

1 | Raw material | Type | Galvanized steel |

| Feeding width | As customer' drawing | ||

| Thickness | 0.3-0.6 mm | ||

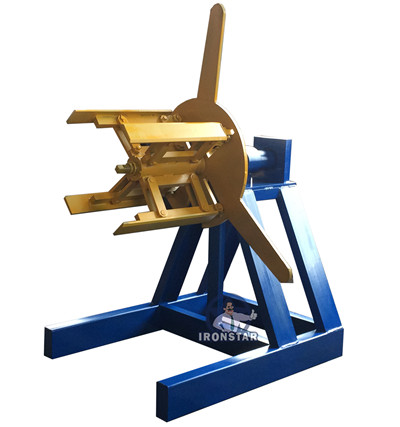

2 | Decoiler | Operation | Manual |

| Weight apacity | 3 Tons | ||

3 | Main body | Roller station | 10 rows |

| Diameter of shaft | 55 mm | ||

| Shaft material | 45# with 0.05mm chrome | ||

| Roller material | 45# with 0.05mm chrome | ||

| Frame | Steel plate welding | ||

| Frame thickness | 16 mm | ||

| Machine size | About 4.2*0.8*1 m | ||

| Machine weight | About 1.5 tons | ||

| Machine color | As customer need | ||

| Operation | Hydraulic automatic | ||

| Working speed | Common speed 30-50 m/min | ||

| 4 | Cutter | Hardness | 50-65 HRC |

| Cutting tolerance | ± 1mm | ||

| Material | Cr 12 | ||

| Operate | Hydraulic cutting | ||

| 5 | Power | Driving way | Chain 1 inch |

| Main motor | 4 KW | ||

| Pump motor for cutter | 3 KW | ||

| Voltage | 380V/50HZ, 3 phase or ass customer' request | ||

6 | Control box | Electric box | PLC control system, inventer |

| Screen | Touchable screen | ||

| PLC brand | Delta made in Taiwan | ||

| Inverter brand | Delta made in Taiwan or SAJ | ||

| Language | Chinese and English or as customer' request | ||

| 7 | Stacker | Operation | Manual |

| Length | 2-3 m | ||

It is used to stand the steel coil and uncoil, keep them work stably

Loading capacity: 3 tons

Coil inner size: 470-530 mm

Work type: Manual operation

Color: As customer' request

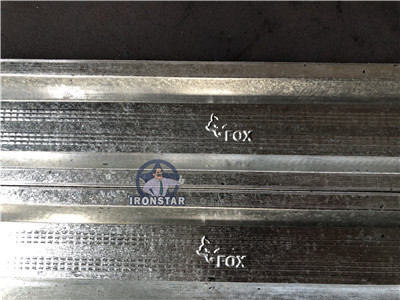

Roller material: 45# steel with 0.05mm chrome

roller surfaces polish, hard plating dealing

Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12, quenching treatment

Insert raw material (steel plate) through the beach to manufacture and process

It can guarantee coil go straight and the out products neat, parallel

Puncher mould located on the machine before cutter

It can punch logo as customer' need, Logo can be digital number or photo

Logo need punch on flat surface, common in different product, it local position not same

DETAL PLC control system

Target piece`s length is adjustable and digit

Two modes operate: automatic and manual type

Button press and screen touch operate, easy operate

Language: Chinese and English or as acustomer' need

Hydraulic oil into the hydraulic oil tank

Pump motor drives the cutter work

Motor Power: 3KW

Hydraulic oil: 46# Oil

add capacity: oil add 3/4 of box capacity

Oil pressure: 8-10 MPa

Length: Common 2-3 m

Operate : Manual work

Used to collect the finished pieces

Support roller to transmit pieces

Easy for panel take away by forklifts

1). Packing method: Nude, seller should guarantee equipment will be moisture-proof, anti corrosive, and will not be damaged during transportation.

2). Payment Term: 30% of total contract value paid by T/T, last 70% paid by T/T after inspection by buyer in seller’s factory while before delivery.

3). Delivery Time: The seller guarantees the equipment will be ready for shipment within 40 working days after receipt of deposit from the buyer.

4). Service: We could send technician to your country to fix the machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 120 per day.

5). Warranty: 36 months During warranty, the replaceable parts are free, but the buyers need to pay for the shipping fee.

6). Package: One complete equipment needs a 20 feet container to hold.