Shanghai Yichen industrial co. LTD |

|

Verified Suppliers

|

|

BTH CNC Stud Welding Machines F 400

Suitable for Capacitor Discharge

Short Cycle and Drawn Arc Stud Welding

The cost-effective entry-level model F 400 impresses

with its high-quality features. A robust welded steel machine frame

as well as the safety housing with protective shields and door are

standard equipment. Series PRO-C and PRO-D stud welding units as

well as the stud welding heads KHA-200F and KKA-200F are applied.

The working area of the machine is 400 x 400 mm. It is suitable for

different welding methods (capacitor discharge, short cycle and

drawn arc stud welding). Even for untrained operators the F 400 is

easy to operate and to program and can be retooled very fast.

| F 400 | ZM | ZG | TN | TM | TG | VN | VM | VG | ||

| Working area X/Y (mm)1) [can be reached by each welding head] | 400 400 | 650 650 | 800 800 | 1000 700 | 1250 850 | 1500 1000 | 1000 2000 | 1250 2500 | 1500 3000 | |

| Welding range2) | ||||||||||

| Stud diameter (Ø) | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | |

| Stud length (mm) | 6-50 | 6-50 | 6-50 | 6-50 | 6-50 | 6-50 | 6-50 | 6-50 | 6-50 | |

| Max. number of stud welding heads | 1 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Max. operating speed X-/Y-axis (m/min) | 6 | 12 | 12 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Positioning accuracy of the welded studs +/- (mm) | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | 0,2 | |

| Operation and programming | ||||||||||

| - software i1stud - compact control Xemo R integrated in the frame | x | x | x | - | - | - | - | - | - | |

| - software i1stud - control desk - compact control Xemo B | - | - | - | x | x | x | x | x | x | |

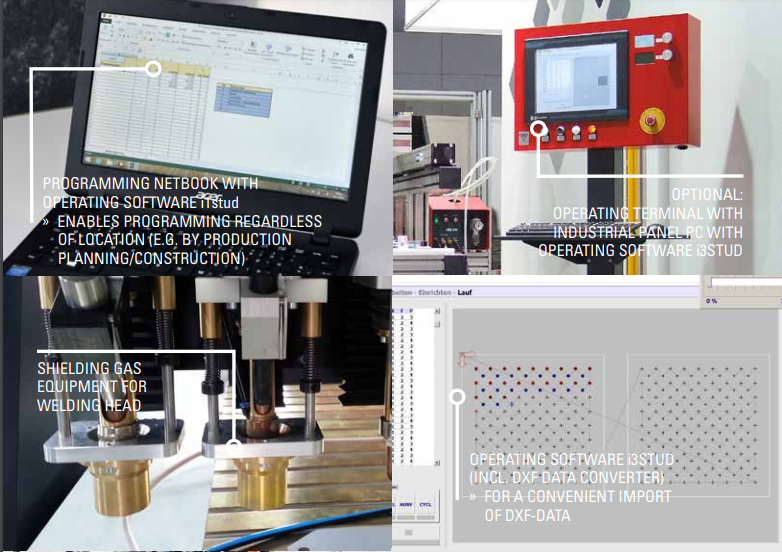

| - Software i3stud (incl. DXF data converter) - operating terminal with industrial panel PC - control Xemo M | o | o | o | o | o | o | o | o | o | |

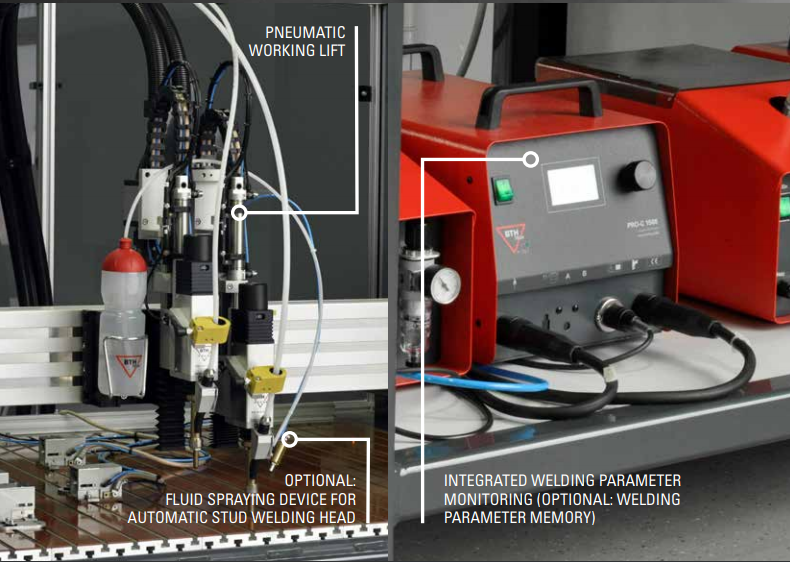

| Welding parameter monitoring3) | ||||||||||

| Welding parameter monitoring | x | x | x | x | x | x | x | x | x | |

| Welding parameter memory with USB-interface for data transmission to a PC | o | o | o | o | o | o | o | o | o | |

| PRO-xDataLog software for real-time transmission of the welding parameter sets recorded by the stud welding unit to a PC | o | o | o | o | o | o | o | o | o | |

| Automatic stud feeding | x | x | x | x | x | x | x | x | x | |

| Options | ||||||||||

| Servo motor-driven Z-axis 250 mm | - | - | - | o | o | o | - | - | - | |

| Servo motor-driven Z-axis 300 mm | - | - | - | - | - | - | o | o | o | |

| Fluid spraying device for each welding head | o | o | o | o | o | o | o | o | o | |

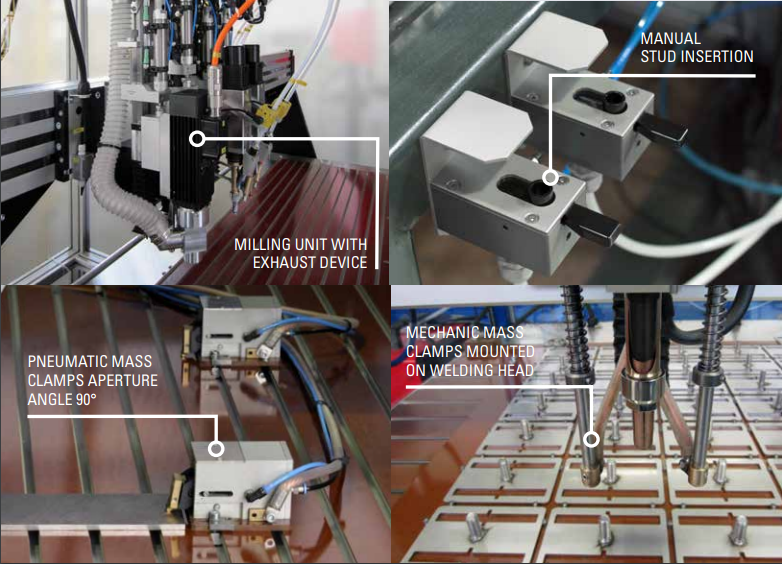

| Milling unit with exhaust device4) | - | o | o | o | o | o | o | o | o | |

| Pneumatic single stud feeding, manual stud insertion | o | o | o | o | o | o | o | o | o | |

| Stud switch | o | o | o | o | o | o | o | o | o | |

| Pneumatic mass clamps standard | o | o | o | o | o | o | o | o | o | |

| Pneumatic mass clamps aperture angle 90° | o | o | o | o | o | o | o | o | o | |

| Mechanic mass clamps mounted on welding head | o | o | o | o | o | o | o | o | o | |

| Pneumatic mass clamps mounted on welding head | o | o | o | o | o | o | o | o | o | |

| Workpiece downholder for each welding head | o | o | o | o | o | o | o | o | o | |

| Shielding gas module for each welding head | o | o | o | o | o | o | o | o | o | |

| Multidirectional balls table | - | - | - | - | - | - | o | o | o | |

| Welded steel construction | o | - | - | - | - | - | - | - | - | |

| Protection devices | ||||||||||

| Housing with door5) | x | x | x | o | o | o | - | - | - | |

| Housing with light curtain | o | o | o | o | o | o | - | - | - | |

| Light curtain | - | - | - | o | o | o | o | o | o | |

| Safety fence | - | - | - | o | o | o | o | o | o | |

| Motor technology/drive | ||||||||||

| Servo motors | x | x | x | x | x | x | x | x | x | |

| Pneumatic working lift/welding head (mm) ((mechanic adjusting range 40 mm) | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Machine frame | ||||||||||

| Welded steel construction | x | x | x | x | x | x | x | x | x | |

| Suitable stud welding units6) | ||||||||||

| PRO-C 1000 | x | x | x | x | x | x | x | x | x | |

| PRO-C 1500 | x | x | x | x | x | x | x | x | x | |

| PRO-I 1300 | x | x | x | x | x | x | x | x | x | |

| PRO-I 2200 | x | x | x | x | x | x | x | x | x | |

| PRO-D 1200 | x | x | x | x | x | x | x | x | x | |

| PRO-D 1600 | x | x | x | x | x | x | x | x | x | |

| Suitable automatic stud welding heads6) | ||||||||||

| KHA-200F with integrated travel measuring system | x | x | x | x | x | x | x | x | x | |

| KKA-200F | x | x | x | x | x | x | x | x | x | |

| Dimensions | ||||||||||

| Width (mm) | 910 | 1550 | 1700 | 2830 | 3080 | 3030 | 2080 | 2330 | 2580 | |

| Depth (mm) | 910 | 1430 | 1580 | 1525 | 1675 | 1825 | 3040 | 4040 | 4540 | |

| Height (mm) | 2000 | 2000 | 2000 | 2160 | 2160 | 2160 | 2360 | 2360 | 2360 | |

| Weight (kg) | 200 | 600 | 800 | 1100 | 1300 | 1500 | 1700 | 1900 | 2100 | |

| Connection values | ||||||||||

| electrical (mains supply, mains fuse external) | 230 V/50 Hz, 16A | 230 V/50 Hz, 16A | 400 V/50 Hz, 16A | 400 V/50 Hz, 16A | 400 V/50 Hz, 16A | 400 V/50 Hz, 16A | 400 V/50 Hz, 16A | 400 V/50 Hz, 16A | 400 V/50 Hz, 16A | |

| pneumatical | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, cleanr | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, clean | ≥ 6 bar unoiled, dry, clean | |

x = Standard, o = Option

1)Other dimensions upon request as special production. 2)Other diameters and lengths as well as special welding elements upon request as special production. 3)By stud welding units PRO-C/PRO-D. For further details see product data sheet stud welding units - capacitor discharge stud welding and stud welding units - drawn arc stud welding as well as product data sheet welding parameter memory PRO-x and PRO-xDataLog. 4)The machine concept is designed for four working stations (series Z: three working stations). If a milling unit is used at the most three stud welding heads (series Z: two working stations) can be mounted. 5)Design as sliding, folding or lift door (if required also pneumatically). Optional: housing with closed top as sound insulation housing. 6)The machines are suitable for all stud welding methods. PRO-C 1000/1500 = capacitor discharge (contact and gap method), PRO-D 1200/1600 = drawn arc and short cycle, KHA-200F = capacitor discharge (gap and contact method), drawn arc and short cycle, KKA-200F = capacitor discharge (contact method)

| ||||||||||