Jiangsu Lebron Machinery Technology Co., Ltd. |

|

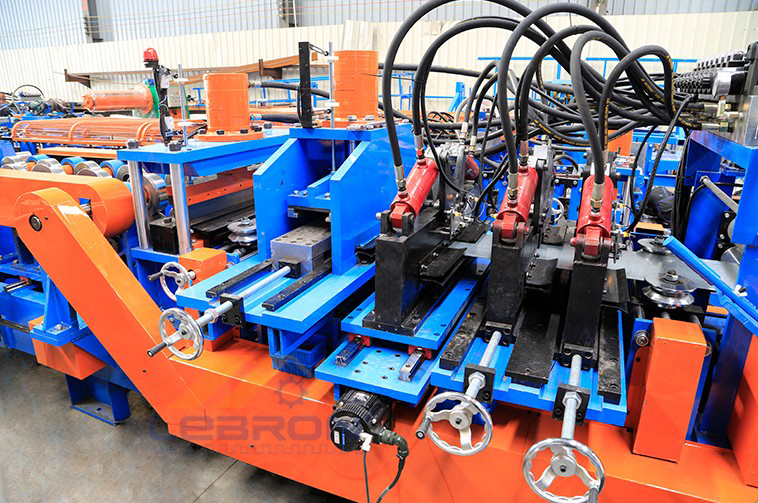

Long Service Time Fully Automatic CZ Purlin Roll Forming Machine High Speed

1. Description of CZ purlin roll forming machine

CZ interchangeable purlin roll forming machine product highlights:

1). The C-type purlins produced have good straightness, good compressive, and bending resistance

2). The Z-shaped purlins produced can be reversely lapped and installed, and the installation strength of the connection point is increased

3). The automatic electronic control system is equipped with an error reporting device to ensure the safety and stability of the production line

4). The drive adopts a deceleration motor plus frequency conversion control, speed control, fixed-length, accurate and reliable positioning

5). Two different profiles of CZ can be rolled, which saves the user's purchase cost and site space

6). The conversion of two types of profiles can be realized without changing the forming roller, with high speed and high efficiency.

2. Technical Parameters of CZ Purlin Roll Forming Machine

| No. | Item | Description |

| 1 | Suitable Material | GI, GL, PPGI, PPGL Coil, Q235 Coil |

| 2 | Suitable Thickness | 1.5~3.0mm |

| 3 | Roller Station | 16 stations |

| 4 | Forming Speed | 8~12m/min (including the punching and cutting) |

| 5 | Roller Material | GCr15 Bearing Steel. Quenched. Hardness: 58~62 HRC |

| 6 | Main Motor Power | 15 KW |

| 7 | Shaft Material | Cr40 steel, Tempering, and Quenching |

| 8 | Shaft Diameter | 70mm |

| 9 | Cutting | Hydraulic Cutting |

| 10 | Blade Material | C12MoV, Quenched |

| 11 | Hydraulic Station Power | 7.5 KW |

| 12 | Drive Type | Single row Chain Drive |

| 13 | Machine Size | 10500mmx900mmx1500mm (L*W*H) |

| 14 | Machine Weight | Approx 8 tons |

| 15 | Machine Frame | 48mm Thick Plate |

| 16 | PLC Control System | Panasonic |

| 17 | Frequency converter | Yaskawa |

| 18 | Encoder | Omron |

| 19 | Servo motor | Yaskawa |

| 20 | Other Electrical Components | Schneider |

3. Main components of CZ Purlin Roll Forming Machine

| No. | Name | Quantity | Remark |

| 1 | 5Tmanual decoiler | 1 | As one complete part |

| 2 | Guiding device | 1 | |

| 3 | Pre-cutter | 1 | |

| 4 | Forming system | 1 | |

| 5 | Transmission system | 1 | |

| 6 | Hydraulic guillotine | 2 | |

| 7 | Support table | 2 | |

| 8 | Hydraulic station | 1 | |

| 9 | Control box | 1 | |

| 10 | Spare parts and tools | 1 | As attaching list |

4. Advantages

Our factory has more than 12 years of working experience in researching and selling. Products are well sailed all over the world, got many compliments from customers.

1). Germany COPRA software design

2). 5 engineers with more than 20 years of experience

3). 15 professional technicians

4). 11 sets of advanced CNC production lines on site

5). Passionate Team

6). Installation engineers can reach your factory within 6 days

7). 1-year maintenance and whole-life technical support

5. Our Service

A. Foreign debugging

If you need it, we will arrange for our professional engineers to help you install and debug the machines well. The buyer should pay $100 per day

B. Guarantee period

The warranty will be a maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during the guarantee period, we will provide the parts free of charge, which is in the conditions of correct operation. (Natural disasters or factors which can’t be forced by humans are excluded).

C. Training

During the installation and adjustment of the equipment, our engineers shall provide the training to the buyer’s personal request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation, and non-standard safety items, testing material and etc.

6. After-Sale FAQ:

1). Q: How to acquire service support?

A: Lebron-Machinery is doing its best to provide timely and convenient service support for the customers, the contents of services include before-sale technical counseling, field installation, operation technical training, application solution training, troubleshooting support, etc.

2). Q: After purchasing Lebron-Machinery’s machine, what kind of training could Lebron-Machinery provide?

A: Lebron-Machinery will provide 7 days of free training. The training place can be in Lebron-Machinery company or in places designated by the customer where installation takes place, this can all be predetermined by clients in the contract.

3). Q: What kind of warranty do Lebron-Machinery’s roll-forming machines provide?

A: Except for the consumables, the whole machine has a one-year limited warranty.

4). Q: After buying Lebron-Machinery’s equipment, are there technicians in charge of supporting on-site installation?

A: Yes, if the equipment is directly sold from Lebron-Machinery, we will arrange for experienced technicians to support the installation and collaboration when the machine arrives. If the device is sold by Lebron-Machinery’s distributors, we will authorize them to send experienced engineers to support the installation and collaboration when the machine arrives. Except the contract made other agreements for the installation.