Jiangsu Lebron Machinery Technology Co., Ltd. |

|

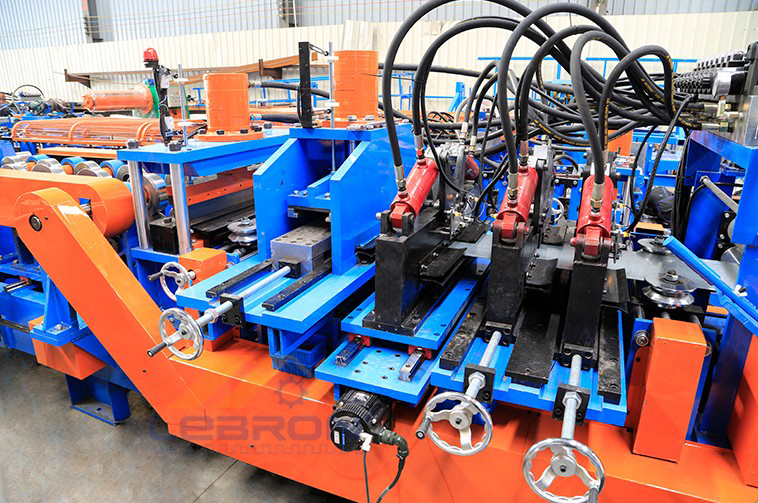

Size Adjustable C Purlin Roll Forming Machine CZ Purlin Roll Forming Machine

1. Description of CZ purlin roll forming machine

A c/z purlin interchangeable roll forming machine has been designed to produce both C and Z steel purlins of any sizes available.

The profile change including cutting dies for C to Z takes at most 30 minutes (just clutches taken out, a 180° turning on some rolling tools and clutches inserted in) and size change needs at most 5 minutes (just input the required distance through the touch screen on PLC control cabinet ). So much efficiency has been improved by this quick-change c/z steel purlin roll forming machine

The main features of the equipment are as follows:

1). No need to change the tool for cutting;

2). Quick type change, any type change within three minutes;

3). Adjustability, the web, flange, and lip can be adjusted, and the adjustment is performed in millimeters;

4). C/Z steel all-in-one machine, C/Z three-step change;

2. Technical Parameters of CZ Purlin Roll Forming Machine

| No. | Item | Description |

| 1 | Main Power | 22 KW |

| 2 | Drive Model | Chain |

| 3 | Machine Frame | The machine frame and structural parts are made of national standard 350H steel, reducing the stress after welding |

| 4 | Roller Material | Cr12 Steel, Finishing-machining. Coated with hard chrome, Chrome thickness: 0.05mm. Quench heat-treatment |

| 5 | Roller Shafts | 40Cr Steel. Finishing-machining. Diameter: φ80 mm |

| 6 | Cutter Blade | Cr12MoV steel. Finishing-machining. Quenched heat-treatment. HRC 58-62 degrees. Wire-electrode Cutting. Finish-grinding |

| 7 | Roller Station | 18 Stations |

| 8 | Roll Forming Speed | 16~20m/min |

| 9 | Suitable Material | Galvanized Steel Coil, Cold Rolled Coil |

| 10 | Suitable Thickness | 1.0-3.0mm |

| 11 | Out-put Length | Controlled by PLC and according to the user’s demand |

| 12 | Structure Design | The width changes by PLC control. |

| 13 | Machine Size | About 10.0m*1.5m*1.7m |

| 14 | Machine Weight | Around 10 Tons |

3. Main components of C Purlin Roll Forming Machine

| NO. | Name | Unit | Qty |

| 1. | Roll Forming Machine | Set | 1 |

| 2. | Hydraulic/Manual Decoiler | Set | 1 |

| 3. | Feeding & Leveling | Set | 1 |

| 4. | PLC Control System | Set | 1 |

| 5. | Hydraulic Punching Device | Set | 1 |

| 6. | Hydraulic Cutting Device | Set | 1 |

| 7. | Hydraulic Station | Set | 1 |

| 8. | Manual Out Table | Set | 2 |

4. Our Advantages

Our factory has more than 11 years of working experience in

researching and selling. Products are well sailed all over the

world, got many compliments from customers.

1). Germany COPRA software design

2). 5 engineers with more than 20 years of experience

3). 15 professional technicians

4). 11 sets of advanced CNC production lines on site

5). Passionate Team

6). Installation engineers can reach your factory within 6 days

7). 1-year maintenance and whole-life technical support

5. FAQ

Q: How to visit our company:

A: 1). Fly to Wuxi Airport directly;

2). By fast train From Shanghai Hongqiao station to Wuxi station, then we can pick up you at our factory.

Q: What should I provide if I want to customize the machine?

A: You need to provide the profile drawing, material, thickness, voltage, and your special requirements. Then, our technology team will analyze and offer you a suitable technical proposal.

3. Q: What is the Warranty?

A: 12 months

4. Q: What can you do if the machine is broken?

A: Our machine's warranty period is 12 months, if the broken parts can't repair, we will send new free parts to replace the broken parts. You need to pay the cost of the machine that exceeds the warranty period. we can negotiate to solve the problem, and we supply technical support for the whole life of the equipment.

5. Q: If need a technician to the workshop to debug and teach, how to do it?

A: We can send technicians to your country to install the machine. The buyer should bear the expenses including visa, round trip ticket, and suitable accommodation, also the buyer should pay the salary of 100 USD/day.