Jiangsu Lebron Machinery Technology Co., Ltd. |

|

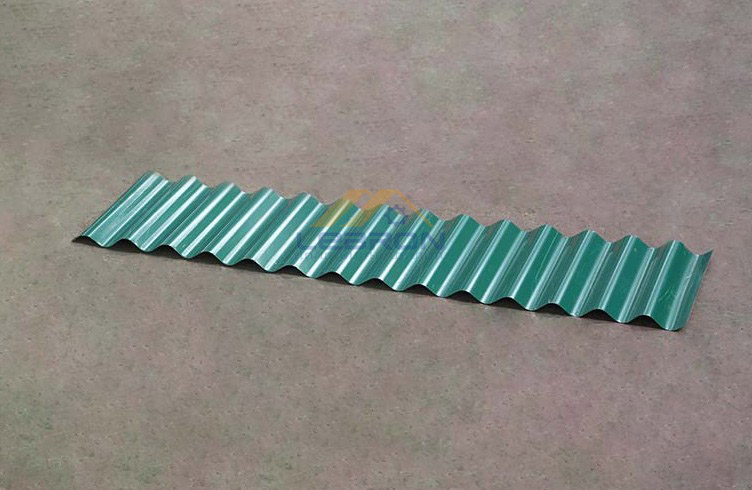

High-Efficiency Blue Color Corrugated Sheet Roll Forming Machine Mitsubishi PLC

1. Main Technical Parameters of corrugated roofing sheet roll forming machine:

1). Main Motor Power: 5.5KW

2). Drive Type: Chain

3). Machine Frame: The machine frame and structural parts are made of national standard 350H steel, reduce the stress after welding

4). Side-wall Panel: Material: Q235, Thickness: 25mm. Finish-machining

5). Welding material: Use high-grade Flux-core welding wire. The strength of the machine frame and structure parts is nearly the same as Vessel parts quality standard

6). Roller: Material: No. 45 steel, Finishing-machining. coated with hard chrome, Chrome thickness: 0.05mm. Quench heat-treatment. Machining key-ways on the roller, set pin-keys

7). Roller Shafts: Material: No. 45 Steel. Finishing-machining. Diameter: φ75 mm.

All the roller shafts machining key-ways, set pin-keys.

8). Cutter Blade Material: High-quality Cr12 steel. Finishing-machining. Quenched heat-treatment. HRC 58-62. Wire-electrode Cutting. Finish-grinding.

9). Liner Bushing: 45# Steel Seamless Pipe. Finishing-machining. Make sure the size and parallelism. Black painting treatment.

10). Bearing: Type: 6210 types, etc. Brand: SXM. Origin: Jiangsu, China

11). Rack rows: 22 rows

12). Forming Roller rows: 21 rows

13). Roll forming speed: approx 10~16m/min (Without cut time)

14). Machine Size: About 8500*1700*1500mm

2. Electric Appliances

1). Frequency converter: Mitsubishi Brand

2). Computer PLC: Mitsubishi Brand

3). Touch Screen: Mitsubishi Brand

4). Low Voltage Apparatus: Schneider Brand

5). Encoder: Mitsubishi Brand

6). Hydraulic Pump Station Motor Power: 2.2 Kw

7). Hydraulic Oil Pump type: YBI-10

8). Hydraulic Valve: Beijing Huade Brand

3. Main Components of corrugated roofing sheet roll forming machine

| No. | Items | Quantity | |

| 1 | 5-Ton Coil Decoiler | 1 set | |

| 2 | Main Roll Former | Direction Guilder | 1 set |

| Rolling System | 1 set | ||

| Post-cutting Device | 1 set | ||

| 3 | Supporting Tables for Finished Products | 2 sets | |

| 4 | Hydraulic Station for Cut Device | 1 set | |

| 5 | PLC Control System cabinet | 1 set | |

| 6 | Tools Box with Spare Parts | 1 set | |