Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Solar PV Bracket Hydraulic Cutting Strut Channel Roll Forming Machine PLC Control

1. Description of strut channel roll forming machine

Basic strut channel comes in the open box section, 1 5/8 by 1 5/8 inch square cross section. A half height (1 5/8 inch wide, 13/16 inch tall) cross-section version is also available, used mostly where mounted directly to a wall as it has significantly less stiffness and ability to carry loads across an open space or brace. A deep channel 2 7/16 inches tall and 1 5/8 inch wide is also manufactured.

The material used to form the channel is typically 12 gauge (0.1046 inches) or 14 gauge (0.0747 inches) thick steel metal.

Several variations are available with different hole patterns for mounting to walls and supports. Punched channel has round holes, large enough for 5/8 inch threaded steel rod or bolts, punched in the top of the channel at regular 1 7/8 inch centers. Half-slot channel has short, rounded end rectangular slots punched out on 2 inch centers. Slot channel has longer slots on 4 inch centers.

The main advantage of strut channels in construction is that there are many options available for rapidly and easily connecting lengths together and other items to the strut channel, using various specialized strut-specific fasteners and bolts. They can be assembled very rapidly with minimal tools and only moderately trained labor, which reduces costs significantly in many applications. A strut channel installation also can often be modified or added-to relatively easily if needed.

2. Main technical parameters of strut channel roll forming machine

| No. | Item | Description |

| 1 | Dimension | 30m x 3m x 2.5m (L*W*H) |

| 2 | Raw material | Mild steel, Galvanized steel coil or strip |

| 3 | Coil width | 300 mm max |

| 4 | Thickness | 1.5-2.5 mm |

| 5 | Forming stations | 20 stations, gearbox transmission |

| 6 | Total power | 45KW AC motor |

| 7 | Track cutting motor | Track cutting motor |

| 8 | Forming speed | 20m/min max |

| 9 | Roller | GCr12MoV Steel, quenched, coated with hard chrome |

| 10 | Shaft | 45# steel with tempering heat-treatment |

| 11 | Shaft diameter | Dia 80mm |

| 12 | Roller station | 20 stations |

| 13 | production speed | 8-10m/min |

| 14 | Hydraulic power | 5.5 KW |

| 15 | Voltage | 380V/50Hz/3Ph |

| 16 | Control system | PLC control system |

3. Main components of strut channel roll forming machine

| No. | Item | Quantity |

| 1 | Uncoiler | 1 Set |

| 2 | Servo Feeder | 1 Set |

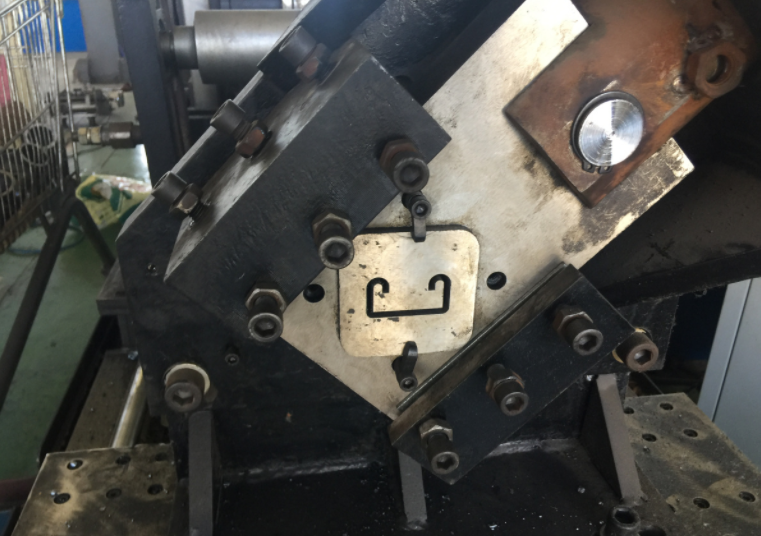

| 3 | Hydraulic Punching Device | 1 Set |

| 4 | Strut Channel Roll Former | 1 Set |

| 5 | Hydraulic Cutting | 1 Set |

| 6 | Hydraulic Station | 1 Set |

| 7 | Ran-out Table | 1 Set |

| 8 | PLC Control System Cabinet | 1 Set |

4. Quality assurance

The company organizes the production as per ISO9001:2008 standard. From design control, process control, inspection control to delivery, installed and service, we all operating a whole strict process control system. The running of a quality system performs quality manual, procedure files, work instruction and related technical and management standard together with standard and regulation layout by the company. Quality system realizes whole screw and whole procedure control completely.