Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Servo Guiding Device Door Frame Cold Roll Forming Machine PLC Control Hydraulic Cut

1. Technical Data

| 1 | Manual decoiler | manual expanding,passive uncoil |

| 2 | Coil width | 150mm(according to the customer) |

| 3 | Roller station: | about 15 stations ( subject to the final design) |

| 4 | Main motor power | 7.5kw |

| 5 | forming speed | 0-15m/min (excluding punching and cutting) |

| 6 | De-coiler capacity | 4T |

| 7 | material of roller | GCr15 |

| 8 | Thickness of material | 0.3-0.5mm |

| 9 | Tolerance of length: | 10m±2mm |

| 10 | Computer adopts | PLC, Siemens |

LBM company is producing and offering outstanding quality range of door frame roll forming machines. These door frame roll forming machines can be customized as per customer requirement based. These door frame roll forming machines are mostly known for its stability and superiority. These door frame roll forming machines can be availed at best competitive prices.

LBM company is producing high quality door frame roll forming machines. Most of them are exported to Australia, Thailand, South Africa, Crotia, Sudan, Kuwait, Bangladesh, Turkey, Russia, etc.

2. Main Accessories

| Serial No. | Commodity | QUANTITY |

| 1 | manual de-coiler | 1 SET |

| 2 | feeding guide and hydraulic punching device | 1 SET |

| 3 | main roll forming machine | 1 SET |

| 4 | hydraulic cutting device | 1 SET |

| 5 | output table | 1 SET |

| 6 | computer controlling cabinet | 1 SET |

| 7 | hydraulic station | 1 SET |

3. Technical process:

De-coiling----- feeding and punching-----roll forming----- -cutting

into length ------output

4. Our Services

1. We provide the technical support for whole life.

2. Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free.

3. When need the technician to go abroad, we will arrange the technician.

4. But the buyer should take all the cost, including Visa, Roundtrip ticket,

suitable accommodation and pay the service fee to the technician with $100/days

5. Packaging & Shipping

Packaging :

1. Tighten to container with steel wire rope and welded machine with container by angel iron

2. Main forming machine and un-coiler is naked (If you need we can also packed with water-proof plastic)

3. PLC contral system and motor pump are packed with water proof paper

Shipping :

1. One 20" container

2. One 40"container

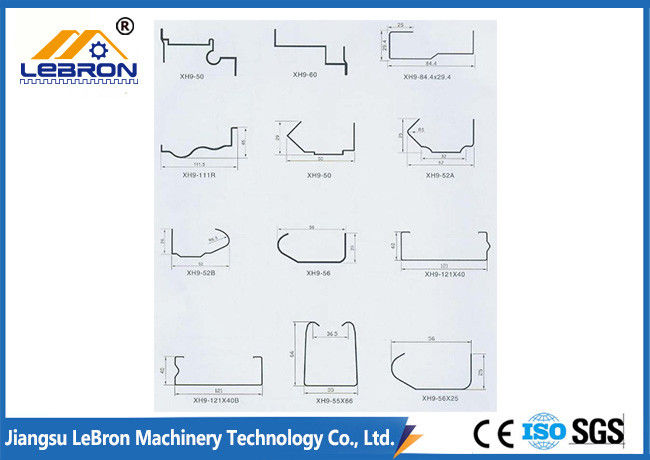

6. Picture