Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Making Warehouse Supermaket Pallet storage rack roll forming machine with manual decoiler

1. Description of storage rack roll forming machine

Storage rack forming machine uses steel as a raw material, by continuous cold rolling molding to produce complex profiles section, type multiple, versatile. We can according to customer design, manufacture different specifications of cold-formed, paint unit equipment.

LBM factory is producing the high quality storage rack roll forming machines, and exported to the foreign countries, such as India, Russia, Ethiopia, Angola, Saudi Arabia, etc.

2. Main technical parameters of storage rack roll forming machine

| Suitable material: | color steel, galvanized steel, aluminum, SS coil or strip |

| Thickness of raw material | 0.4-1.2mm |

| Yield strength of material | 235Mpa-345Mpa |

| Forming speed: | about 8-12m/min |

| Main motor power: | 5.5Kw (Depend on final design) |

| Hydraulic station power | 2.2Kw (Depend on final design) |

| Controlling system | Mitsubishi PLC & Converter |

| Machines weight | about 8T for different profile machine. |

| Machines size | about 11*1.2*1.4m(Depend on final design) |

| Roller Material | No.45 forged steel, coated with chrome, quenched |

| Active Shaft Material | High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. Shaft dia is 50mm. |

| Electric Elements | PLC control panel, transducer imported from Mitsubishi of Japan. Other elements from famous suppliers in China |

| Cutter blade and punch dies | Cr12 mould steel with quenched treatment |

| No. of Work Station | 19 stations |

| Max. Roll shafts Diameter | 76mm |

| Frame | Outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal |

3. Main components of storage rack roll forming machine

| Manual Un-coiler | Max Capacity: 5000kgs Inner diameter of coil: 400-600mm Manual with brake |

| Leveling Device | Ensure the material level and straight The width can be adjusted |

| Auto Main Forming System | Max Feeding width:1220 mm Product width: 1000 & 1020 mm |

| Hydraulic Cutting Device | Cutting way: pause to cut. Hydraulic power: 4 kw hydraulic system. |

| Electrical System | Control system: HMI & PLC control panel. Power: 440V 50Hz (as per local requirement) |

| Run-out Table | Frame: 8# steel groove welded Roller type. Quantity: 1 pc |

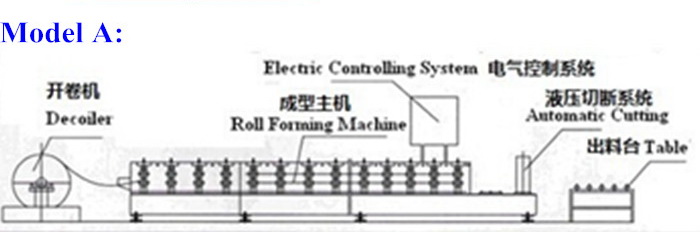

4. Steel storage rack roll forming machine

4. Flow chart of storage rack roll forming machine

5. Our service

Install and Training:

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

After-sale Service:

We provide 12-hour online service for our customers. Phone: +86 15821208506

a .The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller.

When technique men go to the buyer's place to debug the machines, the buyer should pay the

expense of accommodation, and round-trip tickets for the seller’s men. and pay the technician USD60 per

day.

b. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.

6. Delivery