Jiangsu Lebron Machinery Technology Co., Ltd. |

|

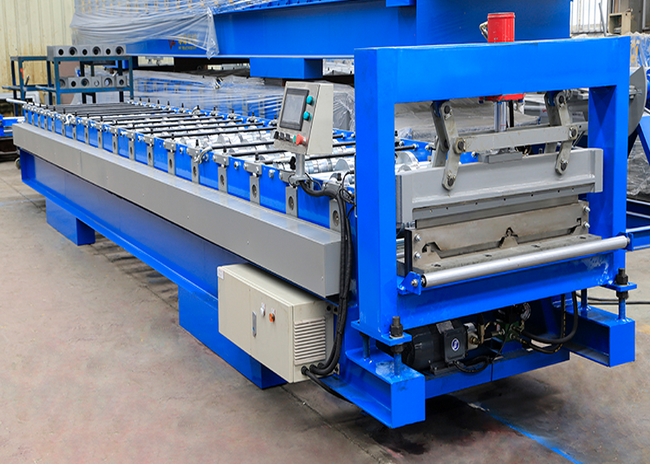

YX25-205-820 type joint hidden roof panel roll forming machine blue and grey color 2018 new type

1. Description of YX25-205-820 joint hidden roof panel roll forming machine:

This type joint hidden roof panel roll forming machine is controled by Panasonic PLC control system, produces the YX25-205-820 type concealed metal roofing sheets.

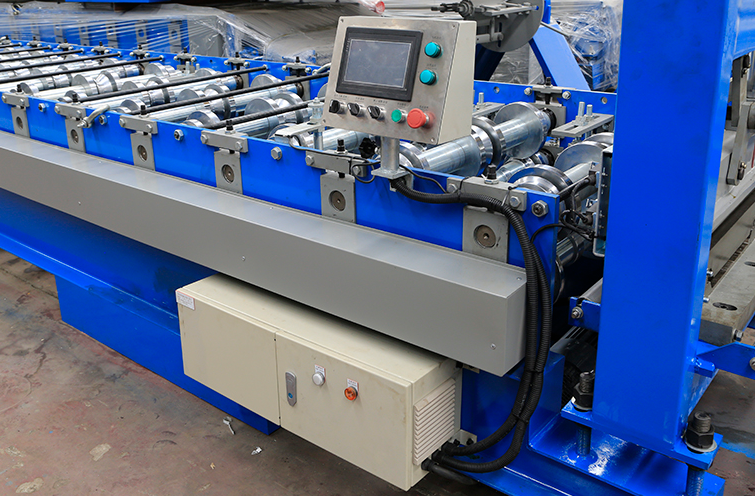

This roll forming machine applies Panasonic PLC control system, including HMI, encoder, inverter and PLC etc, and manufactures the roofing sheets or roof panels fully automaitcally after the input of required cut lengths and quantities. 20 forming roller stations mounted ont the stands, 5.5KW motor equipped on the machine, the concealed roof panel roll forming machine works at a speed around 12-15m/min. The rollers are produced from 45# high grade steel and processed with heat treatment and surface chrome coating treatment etc.

2. Main technical details of YX25-205-820 joint hidden roof panel roll forming machine

| Technical Items | Details | |

| Raw Material | Type | Aluminium & Steel Coils, PPGI, GI, PPGL |

| Width | 400mm, 500mm, 600mm | |

| Thickness | 0.3-0.8 mm | |

| Yield Strength | 235-345 MPa or specially designed for 550 MPa | |

| Finished Products | Cover width | It's up to the final design |

| Length | Adjustable | |

| Required Power | Voltage | 220V/380V/415V/440V |

| Driving Motor | 5.5 KW | |

| Cutting Motor | 2.2 KW | |

| Production Speed of Rollformer | 900-1200 meters per hour | |

| Coil Decoiler Info | Type | Un-powered or Powered |

| Capacity | 5 tons | |

| Rolling Stations | 20 sets | |

| Rollers Material | #45 high quality steel coated with chrome | |

| Rolling Shaft Diameter | 75 mm | |

| Driving Type | Chains Transmission | |

| Cutting Type | Post-cutting | |

| Operation System | Mitsubishi PLC, transducer and touching screen | |

| Supporting Tables | 2 sets | |

| Machine Size | Around 7.5 x 1.1 x 1.4 meters | |

| Machine Weight | Around 7 tons | |

3. Main components of YX25-205-820 joint hidden roof panel roll forming machine

| No. | Items | Quantity | |

| 1 | Coil Decoiler | 1 set | |

| 2 | Main Roll Former | Direction Guilder | 1 set |

| Rolling System | 1 set | ||

| Post-cutting Device | 1 set | ||

| 3 | Supporting Tables for Finished Products | 2 sets | |

| 4 | Hydraulic Station for Cut Device | 1 set | |

| 5 | PLC Control System | 1 set | |

| 6 | Tools Box with Spare Parts | 1 set | |

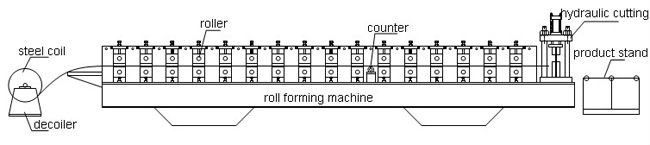

3. YX25-205-820 joint hidden roof panel roll forming machine flow chart

4. YX25-205-820 roof panel sketch

4. Application

5. Our service

Install and Training:

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

During installation and adjustment of the equipment, our engineers shall provide the training to

buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

After-sale Service:

We provide 12-hour online service for our customers. Phone: +86 15821208506

a .The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller.

When technique men go to the buyer's place to debug the machines, the buyer should pay the

expense of accommodation, and round-trip tickets for the seller’s men. and pay the technician USD60 per day.

b. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.

6. Delivery