Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Long Time Service Glazed Tile Roll Forming Machine Plc Control Hydraulic Cutting Device

1. Description of New type color steel tile roll forming machine:

Color steel tile has the good characteristics, such as light weight, high strength, colorful, easy installation, anti-seismic, fire-proofing, rain-proof, long service life, maintenance free, etc. Now, it is widely popularized and used. This machine is suit for the production of various kinds of color steel tiles.

LBM factory is producing high quality color steel tile roll forming machines. Most of the machines were exported to Thailand, Singapore India, Vietnam, Iran, Russia, Ghana, Tanzania, etc.

2. Detailed parameters of New type color steel tile roll forming machine

| Machine Specifications | |

| Weight | Approx 6000 Kg |

| Size | 8m*1.5m*1.2m (Length x Width x Height) |

| Color | Main color: Blue & Yellow (or custom) |

| Suitable Raw Material | |

| Material | PPGI and PPGL Coils, Hot rolled & Cold rolled coil |

| Thickness | 0.3-0.8mm |

| Coil width | 1000mm, 1220mm, 1450mm |

| Yield Strength | 235Mpa-550Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 70 mm |

| Roll Forming Speed | 10-16m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5.5 Kw |

| Electric voltage | 380V 50HZ 3 Phase (or custom) |

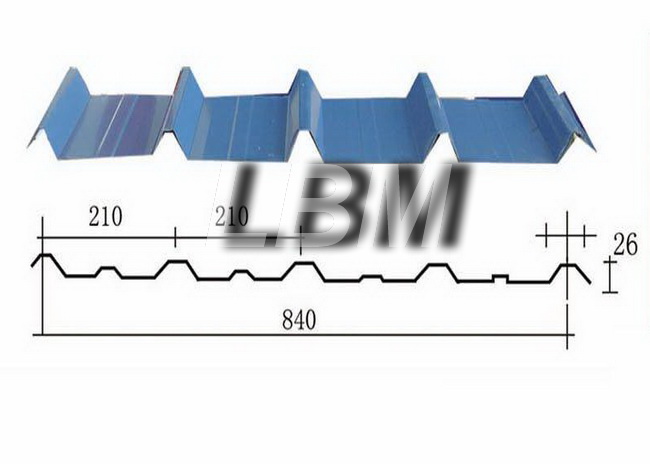

3. Main components of YX25-210-840 type color steel tile roll forming machine

| Manual Decoiler | 1 Set |

| Feeding guiding device | 1 Set |

| Leveling System | 1 Set |

| Roll Forming System | 1 Set |

| Hydraulic Cutting System | 1 Set |

| PLC control box | 1 Set |

| Hydraulic Unit | 1 Set |

| Receiving Tables | 1 Set |

4. Panel sketch

5. Service

· 5 engineers with more than 20 years experience

· 30 professional technician

· 22 sets advanced CNC production lines on site

· Installation engineers can reach your factory within 6 days

· 3 years maintenance and whole life technical support

· Free accessories can be offered to you during the warranty period

6. Our Service and Advantages:

7. Delivery