RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

Wall cladding panel machine or flush panel machine

Wall cladding panel architectural industrial metal wall panels provide design flexibility by combining bold visual effects with easy, cost-effective installation. Multiple profiles are available with a variety of rib patterns. Options for each profile include a no-clip panel, or a clip-fastened panel to accommodate expansion and contraction.Those days wall cladding panels are quite popular are for unmatched performance and stunning visual effects for any commercial metal wall panels, industrial metal siding panels, or retail application.

Meanwhile wall cladding panel is thermo-bonded to a polyethylene or fire-retardant core. Panels are formed by a rout and return process utilizing computer controlled routing equipment. This state-of-art fabrication ensures tight tolerances and accurate panel dimensions. Flush Panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system improves the flush appearance while providing additional strength in our steel or aluminum metal siding panels. Here we can list some popular types for your reference.

Thickness: We need from 0.35 mm to 0.70 mm . Raw material- GI , PPGI & aluminium

G550 in 0.50 mm is the testing and delivery adjusting coil status. Make the machine accordingly ,we can use 406mm & 406.5 mm width coils . That will helpful for 228 mm profile . Its lip is 19 mm only now.

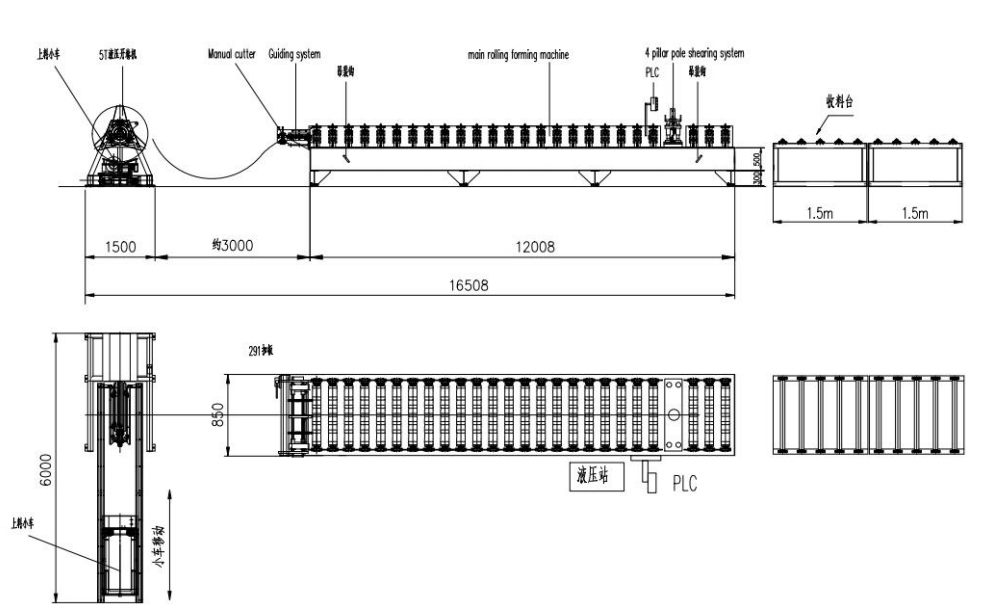

The work flow for roof profile machine

Wall cladding panel machine or flush panel machine

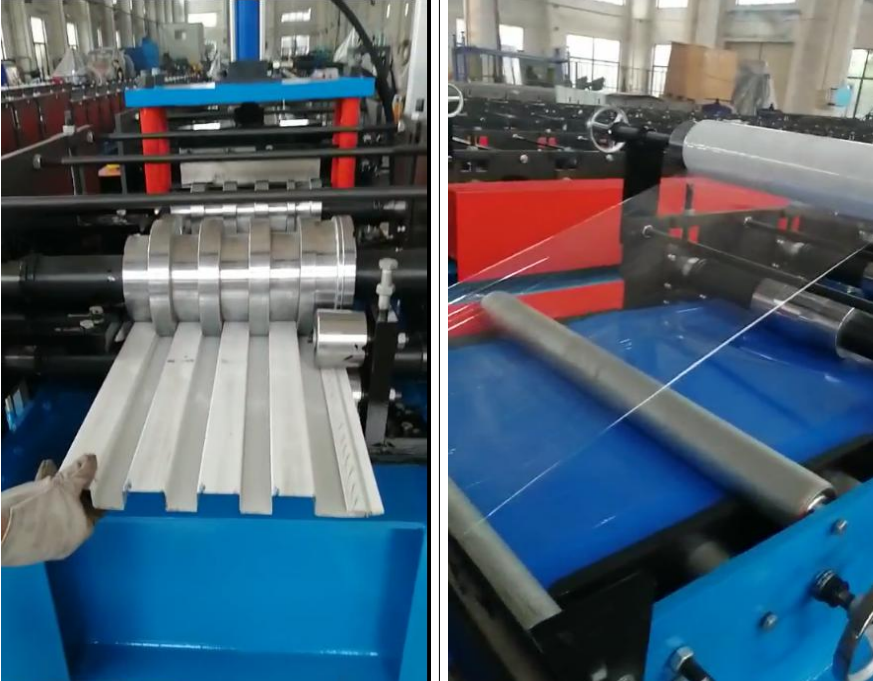

If you want to add the filming system, we can also add for you.

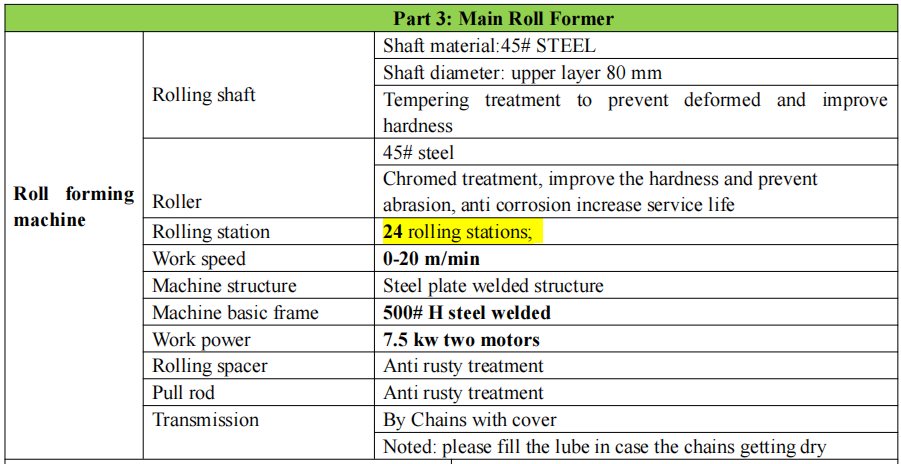

The spacers and rollers

Advantage:

1.For all of our rollers, spacers and shafts, we all mark numbers on it, it’s very convenient for you to

maintenance the machine in the future.

2.There is ball bearings inside the rollers, to make all the rollers run at same speed when machine is run. 3.

Because the rollers inside with ball bearings, our rollers is bigger than others, so work speed is faster. 4. All

rollers and spacers, we do 3mm thickness chrome coating, to increase hardness and anti-rust. Some factories

maybe use 1-2mm chrome coating.

Wall cladding panel machine or flush panel machine working videos for your reference: