RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

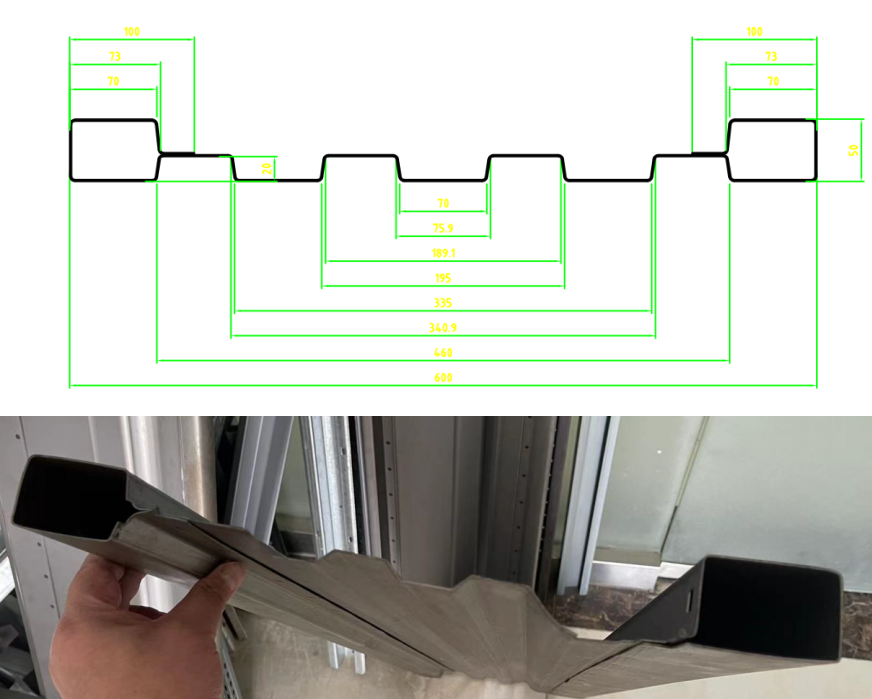

External Truck body Panels Roll Forming Machine

External Truck body Panels Roll Forming Machine is designed to make the truck body side panel in batch fully automatically. As to the welding system, you can choose the rotary welding or laser welding. Take a random drawing profile for your reference to show you more details of this rolling forming machines.

Supported raw material of Truck body Side Panels Roll Forming Machine:

1. Raw materials

(1) Inner diameter of steel coil: φ 508mm

(2) Outer diameter of steel coil (max): φ 1500mm

(3) Steel coil weight (max): 10t

(4) Thickness of steel plate: 1.5 ~ 2.5mm (high strength of thin plate and low strength of thick plate)

(5) Steel plate material: Q235

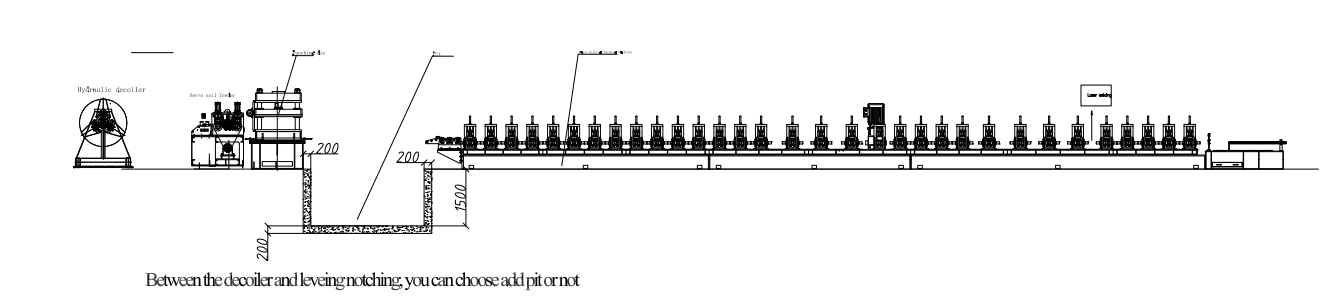

Machine working flow of Truck body Side Panels Roll Forming Machine:

Automatic feeding → metal embossing→ pit looper storage → servo feeding + hydraulic punching and notch → pit looper storage → main rolling forming machine→ tracking roller welding → shaping → servo tracking hydraulic punching and cutting → receiving table

| Each Part Elements of Truck body Side Panels Roll Forming Machine | ||||||

| NO | Item Name | Mode | Qty | Power (KW) | Note | |

| 1 | Automatic decoiler | 10T | 1 SET | |||

| 2 | Metal embossing machine | With separated PLC | 1 SET | 7.5KW | ||

| 3 | Servo coil feeder | 1 SET | 11kw | |||

| 4 | Hydraulic punching and hydraulic Punch notch | 1 SET | Punching SKD11 | |||

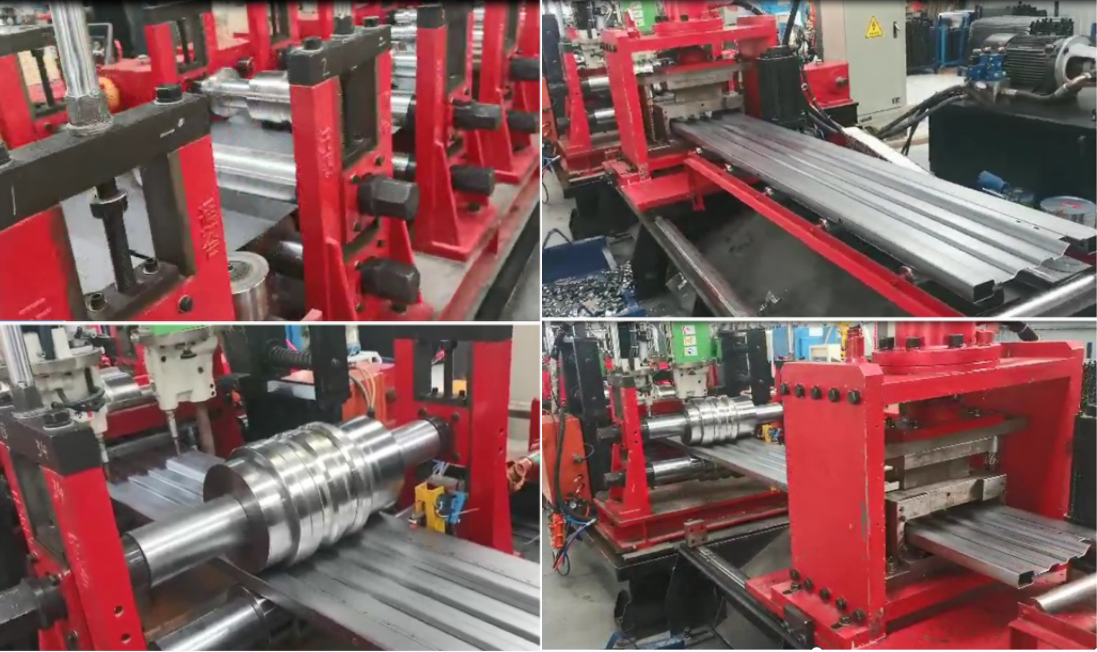

| 5 | Main rolling machine | Molding frame, gearbox system | 1 SET | 37KW | ||

| 6 | Spot welding machine | Tracking roller structure | 1 SET | 200KW | 2 sets of spot welding | |

| 7 | Turkey system | 1 SET | ||||

| 8 | Hydraulic tracking shearing system |

| 1 SET | 7.5KW | ||

| 9 | Receiving table | 1 SET | ||||

| 10 | PLC control system | Whole PLC control | 1 SET | |||

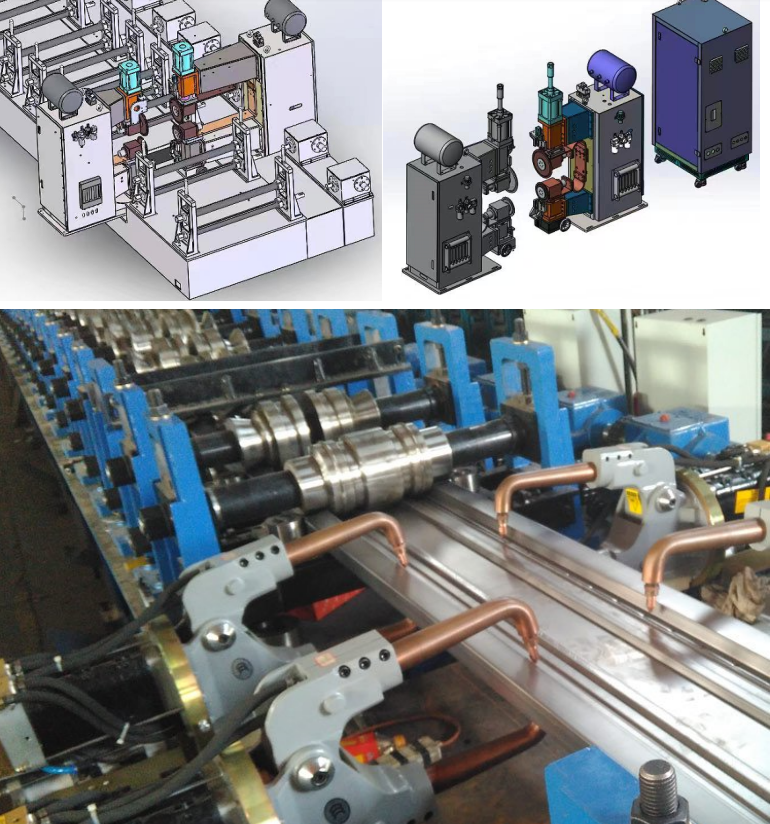

Online roll spot welder (2 sets) for Truck body Side Panels Roll Forming Machine

① High power roll welding machine is used to realize on-line tracking automatic roll welding, so as to enhance the welding quality and working stability. The maximum welding speed can reach 6m / min and meet the requirements of welding position.

② Each action of the welding machine is controlled by PLC. The welding control box can realize the locking of process parameters such as welding current and welding speed, and is interlocked with the electric control system of the whole line.

③ The welding shall be firm and reliable, and there shall be no obvious indentation, false welding and burning at the welding point. After welding, it fits with the lap edge and meets the use requirements.

④ The distance between two welding points shall be 100mm.

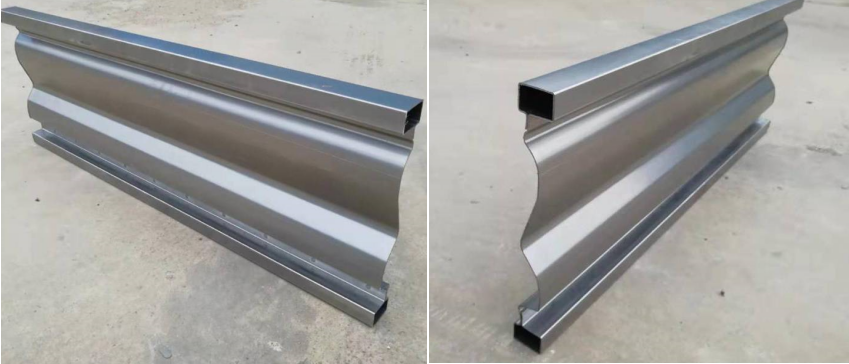

Here are some Truck body Side Panels for your reference:

External Truck body Panels Roll Forming Machine | Truck body Side Panels Roll Forming Machine working videos for your reference: