RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

Stone-coated metal roof tile making machine

Stone-coated metal roof tile is produced by using high-tech. It uses the aluminum-zinc plated steel plate with excellent anti-corrosion performance as the substrate, water-based acrylate as the binder, sintered colored sand as the surface layer, and the weather-resistant acrylic resin It is a new high-grade roofing material with the outermost surface layer (equivalent to paint). Because of its beautiful appearance, light weight, durability and environmental protection, it has become the mainstream product of international roofing materials in recent years and is used in domestic high-end buildings. Here I will show you some popular types for your reference:

Coated metal roof tile is a modern environmentally friendly roofing material with

the basic of 0.6mm Al-zin coated steel.Covering color vermiculite surface which carried under the high temperature technology. It is high-performance, stable, energy-efficient and easy operation.

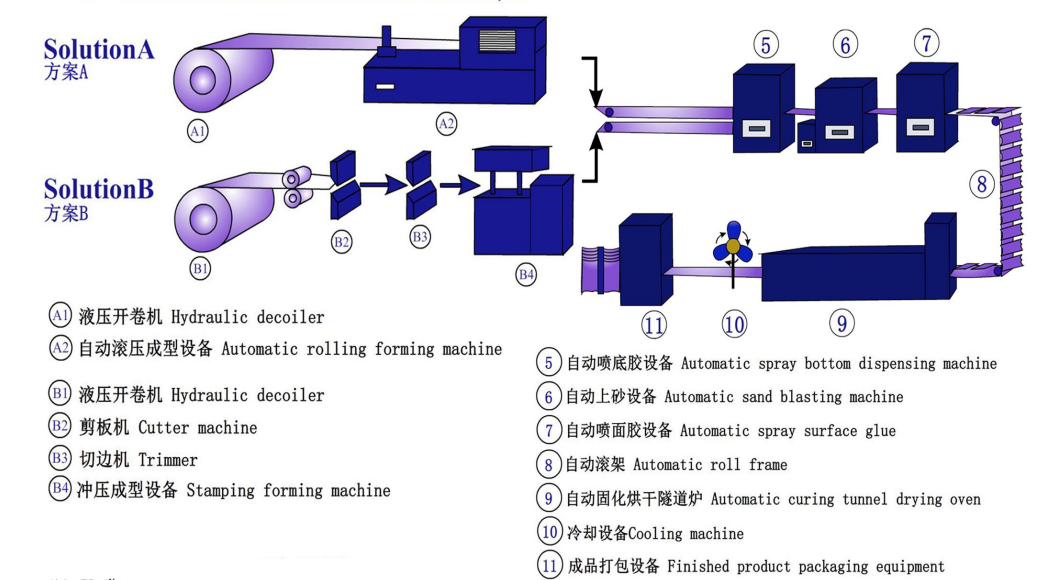

This stone-coated roof tile machine line is included below parts:

1.stone coated line

2. Plate slitting shearing machine

3.flower shearing machine

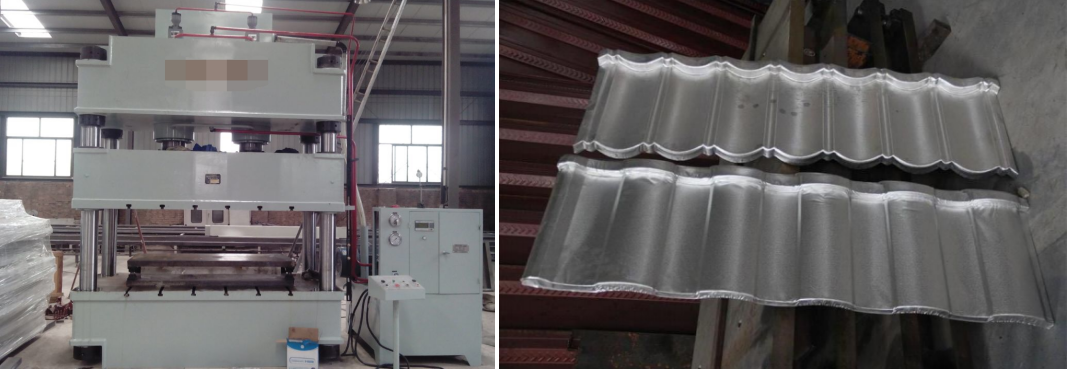

4.Hydraulic press machine

5. roof tile mold

6.bending machine

7. Punch-200 T--450T

Here I will list some important elements of Stone-coated metal roof tile making machine production line:

1. Pressing machine . First we need to press the metal sheet to the tile shape. Different profiles, they need different pressing molds

| NO. 1 Auto bottom glue spraying section | |

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements ) |

| Automatic pressure spray tank | 1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

| Automatic glue machine motor | Servo motor ; Power: 750w ; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set ; Power: 200w |

| Damp proof lamp | 1 pc ; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set ; Power: 7.5kw |

| Dust control of axial flow fan | 1 set ; Power: 200w |

| Agitator | 1 set ; Power: 1.5kw |

| NO. 2 Auto stone coated section | |

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set ; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

| NO. 3 The first time drying section | |

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets ; Range: 0°~160° |

| Infrared heating tube | 30pcs ; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set ; Power: 200w |

| |

| NO. 4 Auto face glue spraying section | |

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pc ; Power:100w |

| Automatic pressure spray tank | 1 set ; Capability: 200kg ; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set ; Power: 200w |

| Automatic glue machine motor | Servo motor ; Power: 750w |

| |

| NO. 5 The second time drying section | |

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets ; Range: 0°~160° |

| Infrared heating tube | 30pcs ; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set ; Power: 200w |

| |

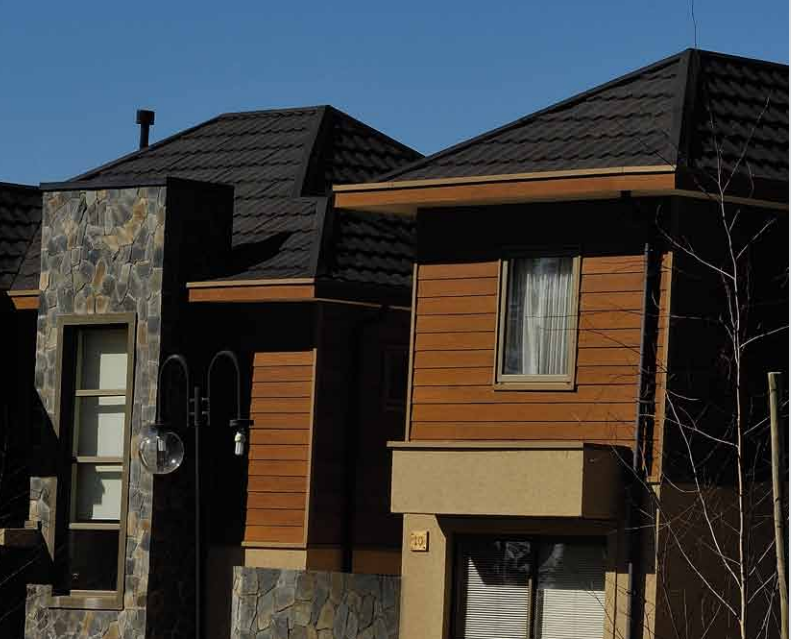

Now let us check the installation effect of the Stone-coated metal roof tile making machine :

Here are stone tile types for your reference:

No matter the machine or the finished product both we can supply, if you want to know more information, please contact us at any time.