RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

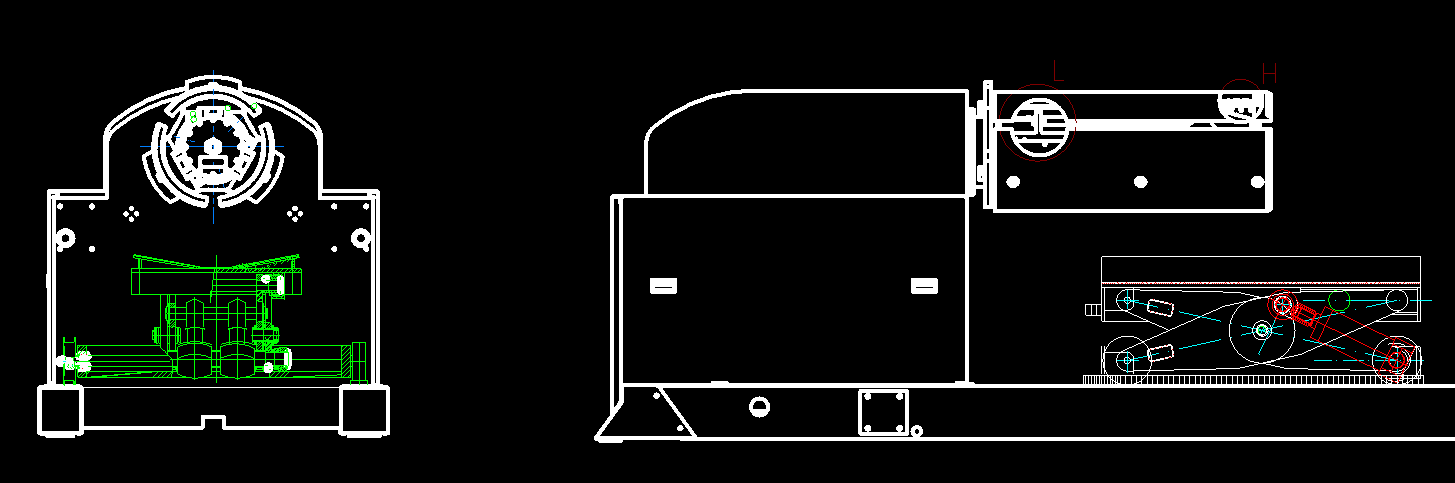

Movable automatic hydraulic decoiler with loading car

A hydraulic uncoiler, which supports the coil plate and provides tension to the steel strip, is composed of a frame, a main shaft, an expansion and contraction drum, and a braking device.

a) Main frame: Made of forged and welded bearing seats made of section steel, A3 steel plate, and # 45 steel, and subjected to annealing and qualitative treatment without deformation; Two bearing seats are bored at once to ensure the concentricity of the spindle installation and prevent radial runout.

b) Spindle: Made of a 40Gr round steel drill with a diameter of 85mm through hole, quenched and tempered, and then finely turned. The working face has a diameter of 190mm and a load-bearing capacity of 15 tons.

c) Expansion and contraction drum: adopt slider type push pull expansion drum form; Four curved plates and a pair of linear cutting sliders, with a diameter increase or decrease Ф 460~ Ф 520; The effective working length is 1300mm, and the overall mandrel ensures the concentricity of the drum during expansion and contraction. The surface of the drum is electroplated with hard chromium.

d) Brake device: adopts pneumatic disc brake components, with adjustable braking force. When parking, the brake is tightened, and when driving, the brake is pulled to ensure that it will not loosen during standby and startup states, to avoid scratching the board surface during loosening.

e) Hydraulic power: push pull expansion and contraction mandrel: hydraulic cylinder model and specification: FA- Ф one hundred and twenty-five × 130mm, using rotary joint oil supply method; Pressure lifting hydraulic cylinder FA- Ф sixty-three × 600 mm.

Today we will introduce one new design hydraulic decoiler with the loading car, it can move alone the rail. As to the rail length we can design as long as you need.

More details of the decoiler:

1. With the pressing arm, the coil will not peel off when long and wide.

2. The loading car for uploading the coil to the shaft exactly and easily.

3. The brake can protect the worker safety when high speed running.

4. PLC can help you adjust the speed easily.

Here is the decoiler testing video for your reference: