RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

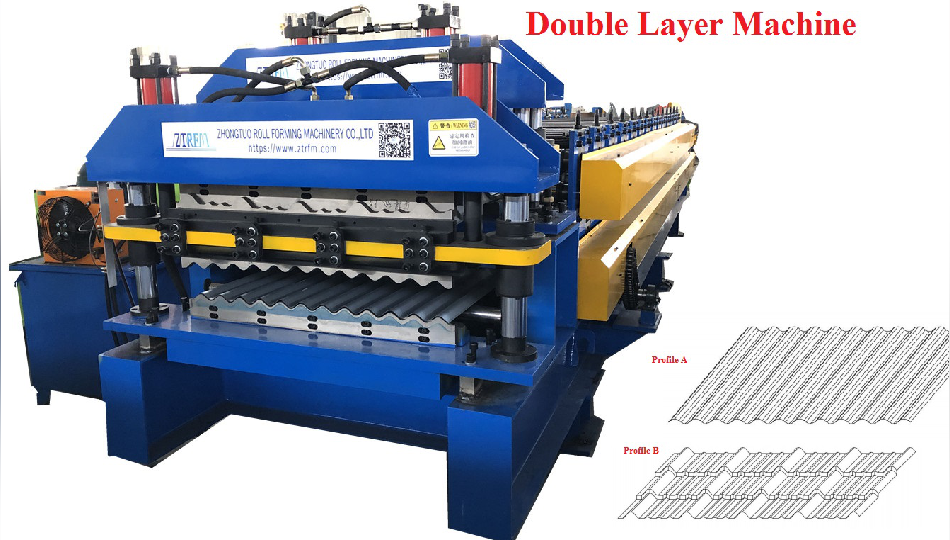

Double layer metal roofing sheet machines for Ecuador

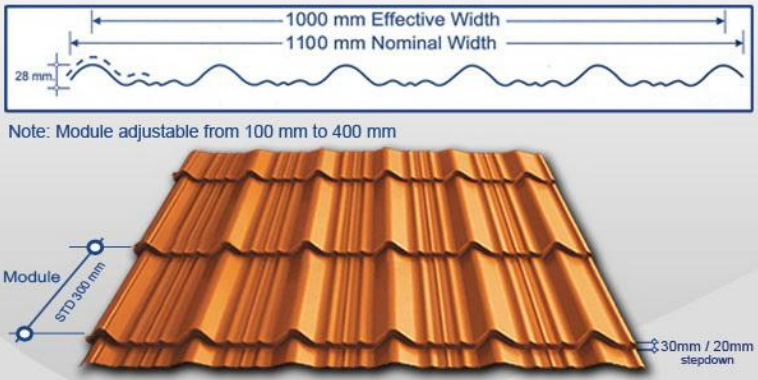

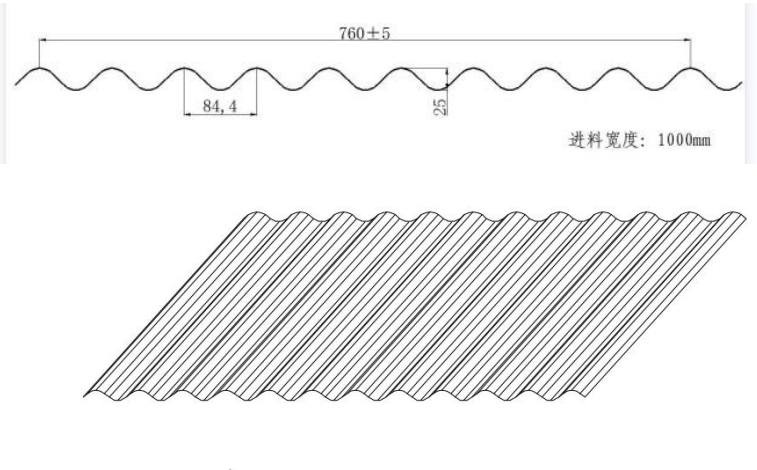

Double layer metal roofing sheet machines for Ecuador one machine for two types roofing sheets and the drawing profile is quite popular for the Ecuador market. One layer is the step tile and another layer is the corrugated roofing tile machine.

Compared to a single layer roof panel roll forming machine, a double layer roll forming machine is desgined to produce two different kinds of metal sheets which can be one trapezoidal roofing and one roof/wall cladding sheet; one trapezoidal roof sheet and one corrugation sheet; one trapezoidal sheet and one metal roof tile; one corrugated sheet and one metal glazed roof tile etc. To sum up, any two of the metal roof panels can be produced by this same double deck roll forming machine. Here we will take two random drawing profiles for your reference:

Double layer metal roofing sheet machines for Ecuador

Double layer metal roofing sheet machines for Ecuador parameters for your reference:

Uncoiler: Manual Uncoiler (a Hydraulic decoiler is optional);

Inner diameter : 480- 520mm;

Outer diameter: 1250mm;

Loading weight: 5TONS;

Material width: 762-1250mm;

Material thickness: 0.3-0.8mm;

Forming speed: 0-12m/min (high speed is optional as per request);

Forming steps: 16-22 forming stations (subject to the technical drawing of profiles);

Material of Shafts:45# high- quality steel;

Diameter of Shafts: 80mm;

Material of Roller: high quality 45#steel coated with hard chrome 0.05mm

Thickness of Siding Plate: 20mm

Transmission: by chain- brackets

Motor Power: 7.5 KW

Material of cutting blade:Cr12 with quenched treatment 60- 62 degrees

Material of pressing dies: Cr12 steel with queching treatment (for glazed roof tiles)

Hydraulic Power: 4- 5.5KW

Cutting Lengths and Quantities: this double deck roll forming machine will automatically cut the final sheets exactly as per required

lengths and quantities clients set through the touch screen on PLC control box

Cutting tolerance: +/ - 2mm

Control system: Panasonic PLC, Inverter, CHNT transformer and HMI

Voltage: 380V/50Hz/3phase or customize according to your country situation.

Leveling part with the manual cutter, and with strong shaft and big rollers.

Strong pillar and shearing system and stepping system.

Here is the finished product pictures for your reference:

For double layer machine, if you want to know more information, please contact us at any time.