RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

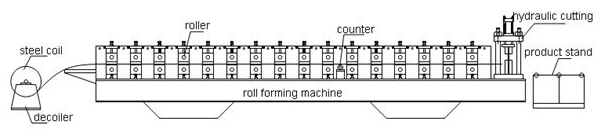

Working flow

Machine components

| No. | Name | Qty |

| 1. | De-coiler | 1 Set |

| 2. | Roll Forming Machine | 1 Set |

| 3. | Hydraulic Cutting Device | 1 Set |

| 4. | PLC Control Box | 1 Set |

| 5. | Hydraulic Pump | 1 Set |

| 6. | Output table | 1 Set |

A. General

| Suitable Material | Q235 or equivalent |

| Material Thickness | 0.25-0.8 mm |

| Material Width | 914, 1000, 1200, 1220 or 1250, as per the drawing |

| Dimension | About 7.9*1.3*1.1m(L*W*H) , as per the drawing |

| Working Space | About 17.9*2.8m(L*W) , as per the drawing |

Length of the Sheet | You can set the length according to your need. It is controlled by PLC which can ensure the accuracy of ±1mm. |

| Cutting | Automatically stop and cutting when it comes to the set length. |

B. Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 11-16, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. |

Treating process: tempering- finish turning, high rigidity, hard to deform. | |

Cutting Blade Material | Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C. Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 5.7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

well-adapted to various conditions, such as moisture, electromagnetic disturbance. | |

| Frequency Converter | DeltaVFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length Measurement Device | Omron, made in Japan. |

| It features with high accuracy and stability. |

D,RFQ

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team to work out the most suitable design and production plan

for the machine.

2: How can we be assured that you will deliver us quality machine

with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the

installation of the machine.

3.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.