RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

Cold Room Sandwich EPS Panel Production Line Roll Forming Machine 12-50KW

No. | Main Parameter of sandwich panel production line | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000/1200mm |

| 3 | Rollers | 13 rows |

| 4 | Dimensions | 6600*1550*1510mm |

| 5 | Power | 25kw |

| 6 | Thickness of the plate | 0.3-0.6mm |

| 7 | Productivity | 15-20m/min |

| 8 | Material of the cutting blade | Cr12 |

| 9 | Diameter of the roller | Φ70mm |

| 10 | Weight | About 3.9T |

| 11 | Voltage | 380V 50Hz 3phases |

| 15 | Control system | PLC control |

Industrial Process And Component Specification

| 3. Core Materials | |||||||||||||||

EPS panel: Volume density16~20kg/m3, Side no straightness ≤1mm/m, radian≤3mm/m. Width Socket panel 1150±1mm H panel Roof Panel 1200±1mm Length unit should greater than 5m, board face should be smooth, denivellation should less than 1.5mm/m 4. Thickness AS Shown IN The Table Below

Should use self-extinguishing flame retardant type, oxygen index greater than 30. EPS board rest of the standard should be consistent with the CB10801 prescribed standards | |||||||||||||||

| 5. Glue | |||||||||||||||

The PU adhesive strength should be greater than 10 n/cm2 Group A: appearance of yellow sticky homogeneous liquid. Viscosity ND0.4 ~ 0.7 Pa. S Group B: look brown sticky homogeneous liquid. Viscosity ND0.3 ~ 0.6 Pa. S A,B group matching ratio should be 1:1. 5. Glue should be without impurities At room temperature and foaming time should be at 20 ~ 40 seconds, curing time should be in 50 ~ 70 seconds. | |||||||||||||||

| 6. Main Component And Function OF Production Line | |||||||||||||||

1. Core material rick for free 1.1. Blanking plate frame: place blanking plate coiled material, each side one, and each can be placed a roll of blanking plate 1.2 Down steel plate frame 1.3 There are two sets of drops of glue, and Make the uniform, to adapt different type plate 1.4 Equipped with a pressure blanking plate into "[" type blanking plate, with power plant A. With the host compound speed synchronous mechanism B. Several sets of forming rollers, To adapt to the produce of 50, 75, 100, three kinds of thickness of the plate C.On both sides of the "[" type sealing plate spacing in 1103 mm can be fine-tuning D. Equipped with two frequency converters to setup control movement speed 1.5.Equipped with steel plate cutting device to cut steel plate 1.6. Equipped with two sets of port plate CAM profiling 1.7. A pressure to strengthen institutions, can raise no pressure or down pressure to strengthen 1.8. One floodlight 2.Main Motor 2.1. Numbers of rubber roller compaction sandwich plate movement 2.2 One set glue and homogenize device 2.3. A set of glue pump components 2.4. A set of pressure to reinforcing rib 2.5. Cutter for cut the upper steel plate 2.6. One electric control box, two inverters, control host speed and the quantity of adhesive glue pump respectively. 2.7. 4 sets of Jack plate forming device, Can be individual adjust the feeding depth by manual and mechanical. 2.8. 4 sets of groover. 2.9. All kinds of beader | |||||||||||||||

3.Two Floodlights 3.1. One escalator 3.2 coreboard cutter 3.3. One electric control cabinet 3.4.One builtin frequency converter for control cutting knife speed. One built-in variable process controller, control cutting knife automatic variable motion. 3.5. Pressure cylinder and reset the cylinder 3.6. One pedestal A .Main transmission rack B. assistant transmission rack | |||||||||||||||

| 7. The Composition OF The Production Line | |||||||||||||||

Down steel plate frame Main motor Cutting machine and the pedestal Transmission rack1 Transmission rack2 Plate holder Lifting Hook | 1 set 1 set 1 set 1 set 1 set 4 pcs 1 pc | ||||||||||||||

Color plate leader clips Brake gear Edge sealing device Edge sealing steel strip holder Touch screen Corrugated roll forming machine Block machine(optional) Color steel slitter(optional) | 2 pcs 3 set 2 set 1 pc 1 set 1 set 1 set 1 set | ||||||||||||||

Holder Slitter Various kinds special spanner Infrared heating tube Dust collection fan Reinforced plastic pipe, sponge, air cushion plastic Corrugated pipe Glue dripping pipe Anchor bolt | 1 pc 1 set 1 set 6 pcs 1 set some 1set 1 set 16 pcs | ||||||||||||||

Spacer Strainer device Tracheal clip, folder Throat Sealing Gum | 16 pcs 2 set 20 pcs 10 pcs 1pc | ||||||||||||||

| 8.Adjusting And Working Condition | |||||||||||||||

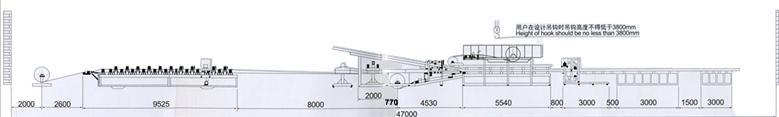

1.Manufacturing shop should be able to put the production line, the raw materials and corresponding operation space 2.Workshop should be configured one above 5 t crane (Single-girder crane also can be configured to meet the requirements), the crane hook height is greater than 3.8 m from the ground. 3.Configurationof above 0.3 m3/7 kg air compressor and moderate pipelines 4. Workshop environment temperature should be greater than 5 ℃ 5.Workshop floor should level off, flatness≤ 5 mm / 10 m, according to the ground plot (the appended drawings) 6. According to the ground plot configured auxiliary power supply, power supply and workshop lighting, etc 7. Prepare debug equipment 8.Color steel: 2 coils, each coil is not less than 3 t, not more than 5 t 9.Glue: conform to the current environment temperature of A, B glue each one barrel, total of 0.45 t 10. Core material: moderate EPS plate of various specifications | |||||||||||||||

1. We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

1. Warranty :One year,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 30 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.Without visiting,we will send you user manual and video to teach you to install and operate.If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things.