RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

3T manual decoiler | 1set | ||

Feeding →roll forming→pressing→t post cutting | |||

out table | 2 set | ||

Hydraulic station | 1set | ||

Control desk | 1set | ||

Spare part list | 1set | ||

Thickness range | 0.4-0.7mm | ||

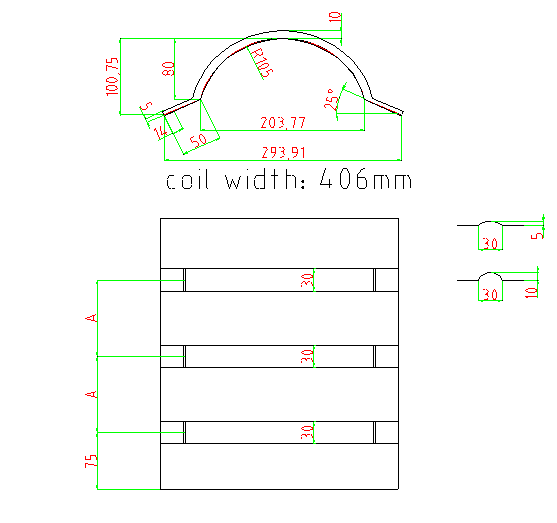

Coil width | 406mm | ||

Length tolerance | ±1.5mm per each pieces | ||

The production flow of equipment | |||

Decoiler→ feeding→roll forming→pressing→post cutting →output table |

Uncoiler | |

Dimensions | 1700mm*1000mm*800mm |

Width of feeding | 300mm |

Capability | 3Ton |

Range of expand(by manual) | 420mm—510mm |

Mode of expand &fight | inner expand &fight by manual |

Way of feeding | manual |

Quantity | 1 |

3T hydraulic decoiler | |

Coil weight (Max) | 3000kg |

Inter diameter | 420mm-510mm |

Maximal out diameter | 1300mm |

Oil cylinder dia | 100mm |

Coil width (Max.) | 500mm |

Working speed | 0-15m/min adjustable |

Main motor power | 4KW AC motor |

Hydraulic power | 3kw |

Frequency converter brand | Yaskawa |

Feeding | |

Entrance table-guide | adjustable |

Entrance width range | 400-420mm |

Entrance and guide roller | diameter is ¢56mm, material is sae1045, surface with chrome |

Quantity | 1 |

Pre-cutting | |

Cutting type | manual |

Function | for coil replacement |

Quantity | 1 |

Forming Section | |

Material of the profile | GI or color steel |

Thickness range | 0.4-0.7mm |

Main motor power | 4kw |

Machine Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

Roll station | 7stations+4 station of side roller (base on final design) |

Roller material | ASTM1045 chrome plated surface with chrome,CNC, |

Shaft diameter | ¢65mm material: SAE1045 with quenching and tempering |

Post cutting system | |

Cutting after forming | Cut the sheet after roll forming to required length |

Material of blade | Cr12 with heat treatment 58-60°1 sets cutter |

Cutting table length | 2m |

Length measuring | Automatic encoder length measuring |

Brand | Omron |

Tolerance of length | 3000mm+/- 1.0mm |

out-table | |

Frame | welding by tube |

Size | about 2.0m long*0.3mwide*0.9mhigh |

Supporter roller | ASTM 1045 with chrome |

Diameter of rollers | 55mm |

Quantity | 2units |

Hydraulic station | |

Hydraulic power | 3kw |

Working pressure | 10Mp adjustable |

Solenoid valve | 2 group |

Hydraulic oil | 46# hydraulic oil |

Quantity | 1 |

Control desk | |

Operating system language | English and Chinese |

Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

Control panel | Button-type switch and touch screen |

Unit of length | millimeter (switched on the control panel) |

PLC brand | Panasonic |

Frequency converter brand | Yaskawa |

Touch screen | Taiwan Weinview |