RFM Cold Rolling Forming Machinery |

|

Verified Suppliers

|

|

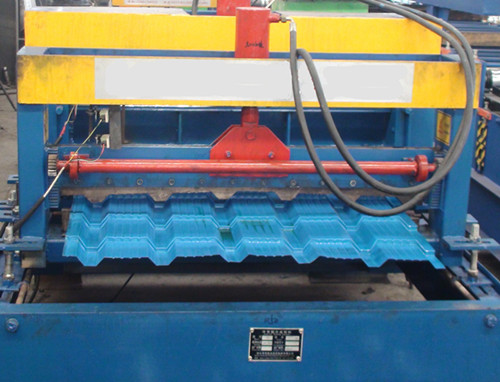

Galvanized Step Glazed Tile Roll Forming Machine 0.40-0.70 mm Sheet Thickness

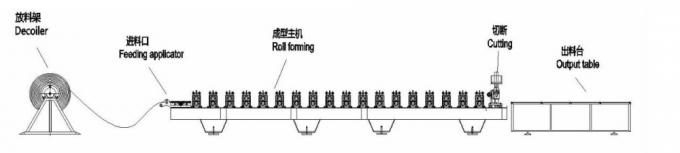

The Chart of Process Flow

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Step formed→

Auto cutting→Products receiving

Equipment sketch map:

Technical Parameters:

| Product name | Tile roll forming machine for sale | |||

| NO. | Items | Parameters | Remark | |

| 1 | Suitable Material | Type | GI/PPGI/AL | |

| Width | 1000/1200/1220/1250mm | Custom | ||

| Thickness | 0.40-0.70mm | |||

| 2 | Product Specifications | Length | Any length | |

| Length Tolerance | ±2mm/6mm | |||

| 3 | Working Speed | 8-12 m/min | Standard machine | |

| 4 | Control System | Mitsubishi/Siemens PLC& transducer | Custom | |

| 5 | Total Power | About 5.5KW | ||

| 6 | Total Weight | About 5.5T | Up to final design | |

Components of Roof Panel Roll Forming Machine :

| No. | Name | Unit | Qty |

| 1 | Manual Decoiler | set | 1 |

| 2 | Main Forming Machine | set | 1 |

| 3 | PLC Control System | set | 1 |

| 4 | Hydraulic Pump Station | set | 1 |

| 5 | Post Cut | set | 1 |

| 6 | Electric Motor | set | 1 |

| 7 | Output Table | set | 1 |

Usage and Feature

The feature looks beautiful, elegant and noble. Those are widely used in building the factory, hotel, and mobile house and so on.

This kind of machine has the best quality and the best price. It has accurate measurement and easy operating. We can design and manufacture the special type machine according to the customers' requirement and we could provide technical guiding, production, installation, debugging and maintenance service to all customers.

FAQ:

1. How to get a quotation?

Give me the profile drawing and thickness,this is the important.

Other spicific requirements is welcome,such as the speed,power and

voltage you want.

2. Terms of payment:

30% T/T, Balance to be paid before shipping after inspection.Also

we accept the payment L/C, O/A , D/P.

3. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can

produce more than 6 kinds of panels.

4. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without

45 working days. If you need machines in a hurry, we can make it

for you less than a month.

5. What is your after-sale service?

Roll forming machine's warranty period is 12months,if the broken

parts can't be repaired,we can send new to replace for free,but you

need to pay the express cost yourself.we supply the technical

support for the whole life of the equipment.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade

company is just for exporting various types of cold roll forming

machine chinas.