Cangzhou Best Machinery Co., Ltd |

|

Auto PLC Control Standard Rib Corrugated Roofing Panel Roll Forming Machine

Main Parameter

| Name | Model/Name | Quantity | Technical Description |

| 1. Decoiler system | Arm type automatic decoiler (With ultrasonice control) | 1set | Arm-type, hydraulic expanding, electrical motor actively release the sheet, with coil cart and pressing arm. |

| 2. Main forming system | Pre-shearing device | 1set | 1.Roller material:No.45 steel with surface hard chrome painted. 2. Roller shaft material: No.45 3. Roller inner supporting structure type: guide column 4.Cycloidal pin gear speed reducer motor driving, the back/forward rollers driven by chain, part of upper/lower rollers driven by gear 5.Cutting blade material Cr12 quenched treatment 6.Punching die material adopts No.45 steel with nitride treatment. |

| Feeding guide device | 1set | ||

| Film covering device | 1set | ||

| Roll forming system | 1set | ||

| Pressing system | 2set | ||

| Post-cutting device | 1set | ||

| Complete safety cover | 1set | ||

| 3. Output system | Support table | 2set | For supporting the finished plate |

| 4. Hydraulic system | 1set | Separated hydraulic station for the main machine and decoiler. | |

| 5. Electric control system | 1set | 1. PLC Control, encoder automatic cutting in length 2. Operation stage: Touch screen+ button 3. AC frequency for adjusting the speed | |

Detail Information

Decoiler

5T manual decoiler

Features: Mandrel and basement are the two components of the decoiler, the mandrel is shrinking expanding by mechanical device manually, after fix coil to mandrel, then put back the coil with mandrel together to basement.

Power: None;

Power of the open and closure of segments: Mechanical;

Power of rotation of segment: Pull by forming system;

Number of segment: 4pcs;

Range of segment expansion: 460 ~ 520mm;

Height of center of the mandrel: 0.65m;

Feeding speed: depend on the roll forming machine speed;

Roll forming machine

Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and coated with hard chrome;

Shaft: manufactured with 45# high grade steel by CNC machine tools;

Supporting frame: steel wallboard to guide the forming station bearing basement;

NO. of roller Stations:up 18groups

Material for Rollers: high grade 45# steel polished and coated with

chrome HRC55-60°

Material for shaft: high grade 45# steel polished and coated with

chrome HRC55-60°

Diameter of shaft: 70mm

Frame panel thickness:14mm

Bottom frame: 36# H-section steel

Cutter device

Function: cutting action is controlled by PLC. The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

Power supply: hydraulic station;

Frame: welding steel frame;

Stroke switch: non-contact photoelectric switch;

Cutting after forming: cut the sheet after roll forming to required length;

Length measuring: automatic length measuring.

Hydraulic system

Hydraulic station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Adopted top brand hydraulic system components to ensure the stability and lifetime, avoid leakage.

Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power.

Electric control system

Automatic length measurement: one unit tooling of length measuring which is lightly pressed on the surface of the steel sheet; the tolling will roll with the moving speed of the steel sheet and then sense to measure its length; length inaccuracy can be amended easily.

Automatic quantity measurement;

PLC is used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved;

Control panel: Button-type switch, LED display length and quantity ;

Unit of length: millimeter;

Motor Over-Load, System Over-Current, Short circuit Protection function;

Display total length and total quantity produced.

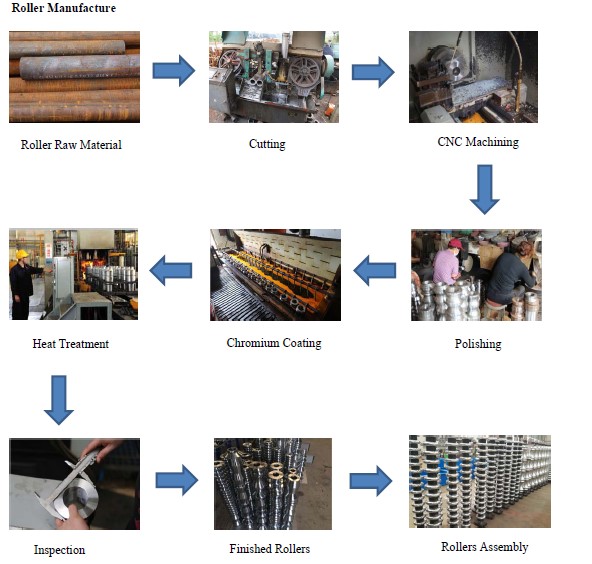

Process Flow