Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

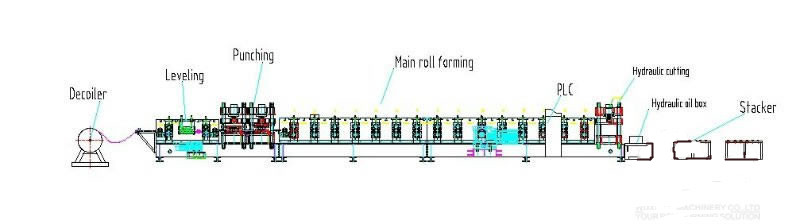

16 Stations Vineyard Post Machine Galvanized Steel Sheet G550 Roll Forming Equipment

Vineyard is widely used for grape stake at Chile, Peru, Spain, France, it is light, easy to move and not easy be broken compare to the normal wooden stake.

d

d

Technical Parameter

| 1.1 | Rolling speed | 2-3m/min |

| 1.2 | Rolling thickness | 1.2-2mm |

| 1.3 | Raw material | Galvanized steel sheet G550 |

| 1.6 | dimension | 6500×600×1200(mm) |

| 1.7 | Effective width | 50mm |

| 1.8 | Roller stations | About 16 stations

|

| 1.9 | Roller material | Gcr15, coated with chrome, Quenching |

| 1.10 | Shaft diameter | Φ60mm ,material is 45# forge steel |

| 1.11 | Transmission | By Chain |

| 1.12 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.13 | Main Motor | 7.5kw |

| 1.14 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.15 | Cutting Tolerance | 6m+-1.0mm |

| 1.16 | Voltage | 220v, 60hz, 3phase |

Main Roll forming machine technique data

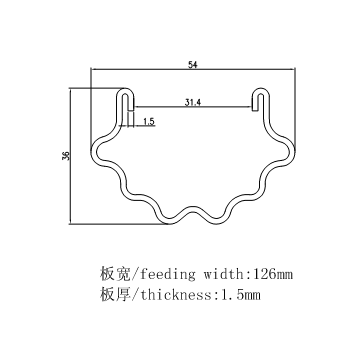

1. Suitable Plate Material: thickness 1.2-1.5mm, Galvanized steel or blank steel

2. Working Speed: about 15-18meters / min

3. Forming machine: about 16 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 75mm), thermal refining

.6. Drive system: Gear box driven

7. Main Power with reducer: 11KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

11. The whole machine is controlled by industry computer-PLC.

Machine operation: Manual and full automatic mode at same time with limit switches, and panel support device

Working Flow of Roll Forming Machine

Decoiler----feedingwithguide---Punching----Rollforming----Cutting----Products collecting

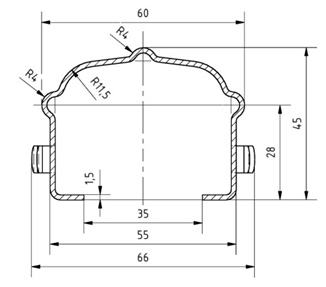

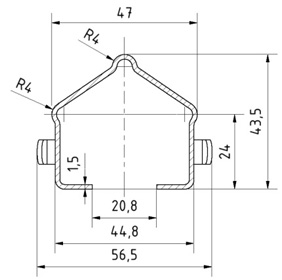

Profile of product

Loading pictures

After-sale Serive

- The seller take responsibility to installation and

commissioning of the equipment and free training. After machine

arrive the destination, by the request of the buyer , the seller

will provide 1 technical engineer to guide installation and

training , and the buyer should give the technical person with full

cooperated.

- Installation period: about 5 days after the complete

preparation by the buyer such as the foundation and all necessary

accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the

buyer should pay for installation and commissioning fee 100$/day to

the point account of the seller. The two-way ticket,visa, food,

hotel , the translator and insurance are all should provide by

buyer with full responsibility.

-The seller supply technical data (including forming

mould drawing, electrical elements drawing and equipment drawing

etc.)