Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Partial Cassette H Punching Hole Stud Track Drywall Roll Forming Machine

Technical data

| Items | Specifications | |

| Material of coil | Material Thickness | 0.3-1.2mm galvanized steel |

| De-coiler | Weight | 3 ton passive decoiler |

| Forming system | Rolling Speed | 10 m/min |

| embossing | 1 set of rolls | |

| Roller Stations | About 13 stations forming | |

| Roller Material | Cr40 Steel with quenching | |

| Shaft Material | 45# Steel Diameter 75mm shaft

| |

| Maim Motor Power | 5.5 kw | |

| Hydraulic cutting Power | 4 kw | |

Cutting system | Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 | |

| Tolerance | +-1.5mm | |

| Cutting blade | 1 set of cutting blade | |

| Electrical control system | Electric Source | 380, 50HZ,3 phases |

| Control System | PLC Delta | |

| Weight | About 4 tons | |

| Way Of Drive | 1 inch single chain | |

| Size of machine | Length 7500mm* Width 600mm* Height 800m |

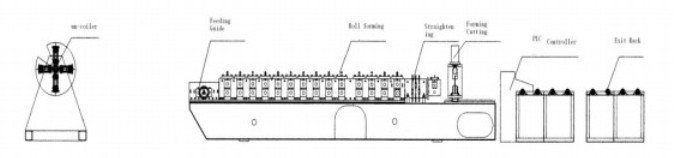

Working Flow:

Decoiler—feedingwithguide—Rollforming—punching&Cutting—Products collecting

Profile Drawing:

with punching holes

To make all of the 6 profiles in one machine by changing spacers

Machine List:

| 2 ton double heads de-coiler | 1 set |

| Hydraulic punching device | 1 set |

| Main roll forming machine | 1 set |

| Cutting device | 1 set |

| Cassettes for different flange | 2 sets |

| PLC Control box | 1 unit |

| Hydraulic station | 1 unit |

| 4 meters out table | 1 unit |

| Safety cover | 1 set |

| Extra punching die | 1 set |

| Extra cutting blade | 1 set |

| Embossing | 1 set |

Cassettes:

Loading Pictures:

Our After-Sales Service Commitments

Sussman hereby solemnly promises: We implement the “three guarantees” service policy for any equipments sold by Sussman, provide free of charge installation guidelines, commissioning and maintenance of the equipments, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipments, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipments:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipments, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Sussman will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Sussman is doing the installation and test running of the equipments for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), three guarantees including the electricity parts, the rolls, the shafts and punching& cutting moulds, then, upon the Buyer’s request, Sussman will eliminate the failure;

4. Sussman will inform all its Buyers about any upgrades and significant product improvements. Sussman will provide equipment modifications based on their costs. Sussman will provide Buyers with high-quality after-sales services in a careful and responsible attitude, provide very strong guarantee for the Buyer’s normal production.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email