Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

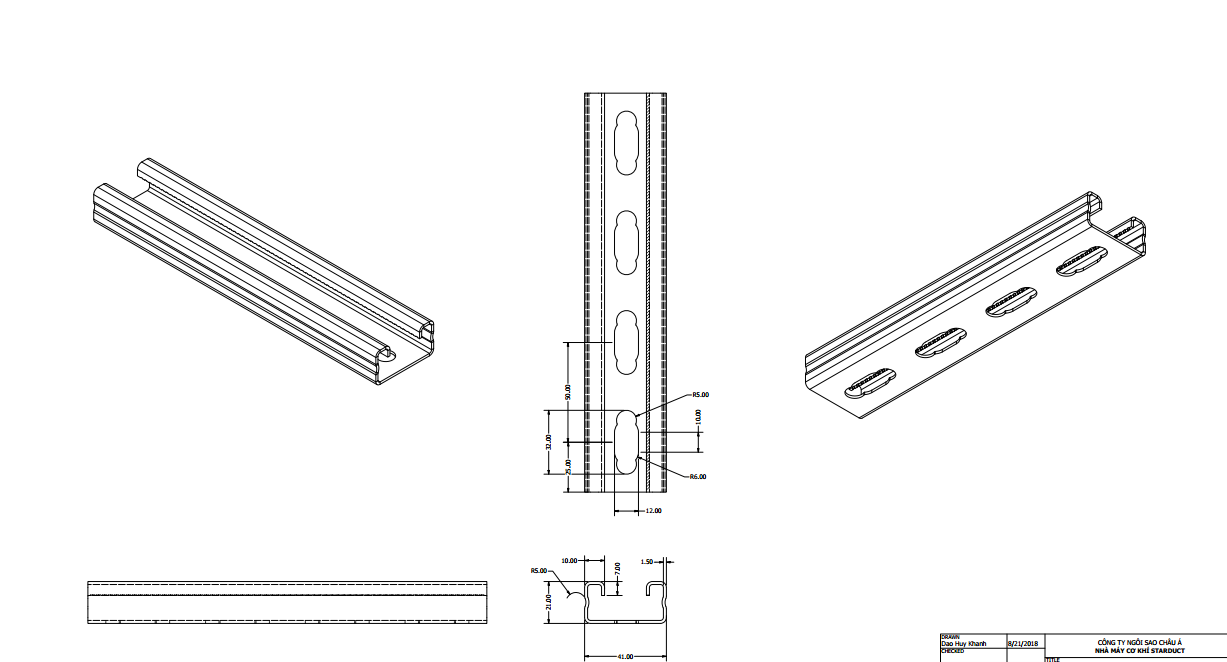

41*41mm Strut Channel Roll Forming Machine For Solar Frame

41*21mm 41*52mm 41*72mm

1. Solar Strut Channel Technical Parameter

1.Forming thickness: 2.2-2.5mm,galvanized coils yield strength≤G250MPa

2.working Line speed: 12M/min(not include cutting and punching stop time)

3.Max speed: 3-4M/min include cutting and punching stop time

4.Hydraulic punching device: 1 set

5.roller stations: about 16 stations main roller

6.material of roller: bearing steel, quenching treatment.

7.material of main shaft: 45# fine steel

8.diameter of main axis: ¢75mm

9.main motor power: 7.5kW

10.motor power of hydraulic station: 4KW

11.hydraulic station pressure: 12MPa

12.electric control system: whole line adopted PLC control, Panasonic PLC

13.cutting type: hydraulic drive, cut after forming

14.material of cutting blade: Cr12 , quenching process

15.Drive way: Chain drive

16.Touch Screen--Panasonic Japan

17. Encoder--Omron, Japan

18 Electric parts--Schneider

2. Solar Strut Channel Machine Components

| S.N | Equipment name | Quantity |

| 1 | 3T passive un-coiler | 1 set |

| 2 | Feeding guide | 1 set |

| 3 | Main roll forming machine | 1 unit |

| 4 | Main roll forming machine | 1 set |

| 5 | Hydraulic cutting | 1 set |

| 6 | control box | 1 set |

| 7 | Out tables | 2 units |

| 8 | Spare parts | 1 package |

| 9 | Safety cover | 1 set |

3. Solar Strut Channel Application

4.Profile Drawing

5. Machine Layout

6. Our Services

Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

1. As the factory, we will recommend the right profile machine to customer, and give the professional advice.

2. Confirm the final decision during the discussion.

3. The sale person will give customer updates for each period during the production process.

4. We finish the machine within the confirmed date, and shipping the goods to customers safely and faster.

5. Provide the right documents to customers.

6. Give the tips(include photos, videos and manual) for installation and operation.

7. If the buyer can not make the installation or machine appeared the problems, if possible, we will arrange our engineer to debug within one week. The charge for technician include the visa, round tickers, food, accommodation and USD100/person/day for salary.