Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

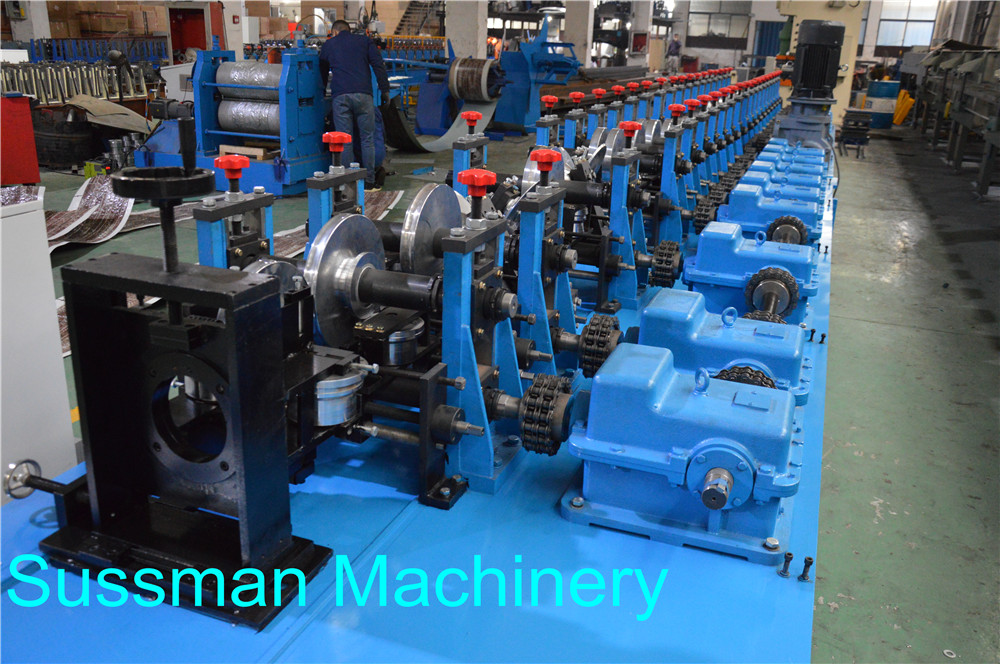

CE Certification 1.5-3.0mm Shelving Rack Roll Forming Machine With 18 Stations

Roll Forming Machine Technical Parameter

Main Specifications

Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or

blank steel

Working Speed: 8-12 meters / min

Forming Steps: 18 stations

Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal

refining

Driven system: Gearbox drives

Main Power with reducer: 11KW WH Chinese Famous

Cutting: Hydraulic Cutting Cr12mov

Material of Cutting Knife: Cr12Mov, Quench HRC58-62

Hydraulic Station Power: 4KW

The whole machine is controlled by industry computer-PLC.

PLC--Delta Japan English and Chinese Language

Touch Screen-Delta

Encoder--Omron, Japan

Electric parts--Schneider

Machine’s Components

|

Working Flow of Roll Forming Machine

Decoiling-- Leveling---Servo following-Punching---Roll

Forming----Cutting----Product Collecting

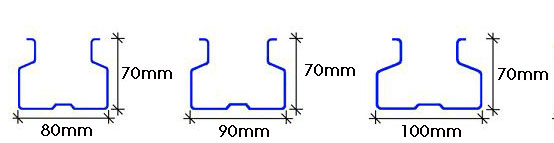

Profile drawing

Three profiles can make in one machine, change the size by

spacers

Packaging & Delivery

Standard package with film, plastic and steel wire. (or customized)

1.Need about two 40ft containers for loading one set machine

completely

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film

3. Spare parts and some small parts packed in plastic tooling box

4. All Components Fixed by steel wire with Container.

Delivery Detail:Shipped in 75 working days after payment

Advantage for Roll Forming Machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Afrer-sales service

Exhibition New:

You are warmly invitated to visit our booth at 2017 Thailand

International Building Materials Exhibition at Bangkok May 2nd-7th,

our booth No is N603-3