Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

High Speed 15-30m / Min Deck Floor Roll Forming Machine Thickness 0.8 mm -1.2 mm

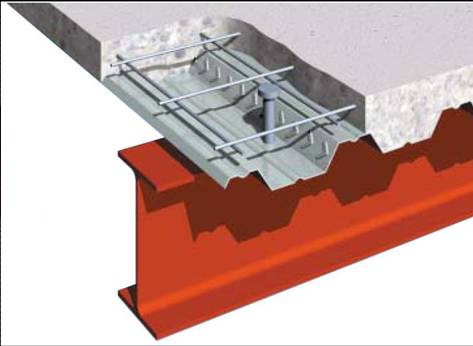

Metal deck steel produced by this Metal Deck Roll Forming Machine, it has high strength with big wave length. It not only save steel mold plate but also reduce the weight of the storey.

Tiles Making Machine are looked beautiful, elegant and noble. It can be widely used in garden-style factory, traveling scenic spots, hotel, exhibition center, villa, civil construction and so on

Normally the material thickness is from 0.7-1.2mm.

Technical Parameter

| S.N | Items | Descriptions |

| 1 | Rolling Speed | 15-30m/min(cutting time is not include) |

| 2 | Steel sheet Thickness | 0.7-1.2mm color painted sheets and galvanized steel |

| 3 | Coil width | as the final drawing |

| 4 | Control System | PLC Delta |

| 5 | Roller Stations | about 28-30 stations |

| 6 | Roller Material | 45# forge steel, coated with chrome |

| 7 | Shaft Material and DIA | ¢90mm,material is 45# forge steel, Chrome with quenching |

| 8 | Main Motor Power | 15kw Anhui wannan Brand |

| 9 | Hydraulic Pressure | 12Mpa |

| 11 | Tolerance | +-1.5mm |

| 12 | Power supplier | 380V, 50HZ,3 phase |

| 13 | Way Of Drive | 2 inches single chain |

| 15 | The size of the forming machine | About 15000*1500*1200mm |

| 16 | Machine weight | about 10 tons |

Machine working flow

Automatic decoiler--feeding with guide--Pre-cutting----Roll forming----Cutting---Out put tables

Machine Component

10 tons hydraulic de-coiler with coiler car | 1 set |

Main roll forming machine | 1 set |

Pre cutting device | 1 set |

PLC Control box | 1 set |

Hydraulic station | 1 set |

4 meters conveyor | 1 set |

6 meters auto stacker | 1 set |

| servo following cutting device | 1 set |

| Servo motor | 1 set |

Profile Drawing

We will check the machine first, before loading the container,

First, make some protection on the machine, Such as, we will mpaint

the coil on the roller and shaft, in case the roller and shast got

corrosion and rusty during long time delivery

Second, we will make the plastic package on the easy damage parts,

and fix all the parts into container by the steel wire rope, and

ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container